PDR (Paintless Dent Repair) for steel panels is a specialized collision repair technique that restores damaged car bodies without sanding or repainting. Using tools like air bags and metal straighteners, technicians gently push and pull metal back into its original shape, preserving the vehicle's finish and reducing costs. This eco-friendly method minimizes waste, saves time, and offers a cost-effective alternative to traditional dent repair for various industries, including automotive and architectural.

“Uncover the transformative power of PDR (Panel Damage Repair) in the realm of steel panel maintenance. This innovative technique offers a seamless solution for restoring damaged or dented steel surfaces, enhancing their aesthetic appeal and structural integrity.

In this comprehensive guide, we’ll explore the fundamentals of PDR specifically tailored to steel panels. From understanding the process to uncovering its diverse applications, you’ll gain valuable insights into why PDR is revolutionizing steel panel repair.”

- What is PDR for Steel Panels?

- The Process of PDR on Steel Surfaces

- Benefits and Applications of PDR for Steel Panels

What is PDR for Steel Panels?

PDR for steel panels, or Plastic Deformation Repair, is a specialized technique within the broader field of collision repair focusing on restoring damaged car bodies made from steel panels. Unlike traditional car paint repair methods that involve sanding and repainting, PDR uses a range of tools and techniques to push and pull the metal back into its original shape without leaving visible scars or needing extensive painting. This non-invasive approach not only preserves the vehicle’s original finish but also reduces the time and cost associated with conventional collision repair.

The process involves several steps, including assessing the damage, using specialized tools like air bags and metal straighteners to gently manipulate the panel back to its original form, and then verifying the results with precision measurements. By minimizing the need for painting, PDR not only helps car owners save money but also contributes to a more sustainable automotive industry by reducing waste generated from repainting processes, making it a popular choice in modern collision repair practices.

The Process of PDR on Steel Surfaces

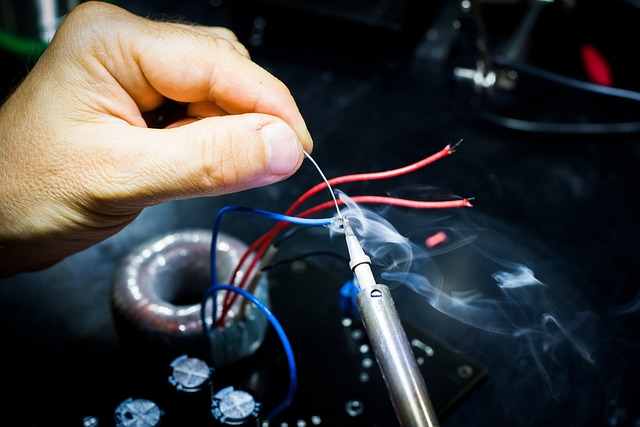

The process of PDR (Paintless Dent Repair) for steel surfaces involves a series of specialized techniques to remove dents and dings without the need for traditional painting or sanding. This method is particularly effective for steel panels, which are commonly used in automotive manufacturing due to their durability and strength. The first step in PDR for steel panels is to assess the dent’s size, depth, and location. Technicians use specialized tools, such as metal picks and paddles, to gently pry out the dented area without causing further damage or deforming the panel.

Once the dent is accessible, a range of tools, including mallets and air guns, are employed to realign the metal fibers to their original position. This process, known as “malletting,” requires precision and skill to ensure the panel returns to its original shape without leaving visible repair marks. The final step involves polishing the area to blend it seamlessly with the surrounding surface, ensuring the repair is virtually invisible. PDR for steel panels offers a cost-effective and efficient solution in vehicle body shops and collision repair centers, providing an alternative to traditional dent repair methods.

Benefits and Applications of PDR for Steel Panels

PDR for steel panels offers a multitude of benefits that make it an attractive solution for various industries. One of its key advantages is its versatility; this non-destructive technique can be applied to repair and restore a wide range of metal surfaces, including steel panels used in automotive, architectural, and industrial settings. By minimizing damage and preserving the original material, PDR is ideal for tire services and auto repair shops looking to provide quality, cost-effective repairs without replacing entire components.

Additionally, PDR is an environmentally friendly option compared to traditional methods that often involve hazardous materials and extensive welding. This makes it a preferred choice for modern, eco-conscious automotive repair facilities. The process can restore damaged steel panels to their original condition, enhancing the aesthetics of vehicles, buildings, or other structures. Moreover, PDR can save businesses time and money by reducing the need for expensive replacement parts, making it a valuable asset in any well-equipped auto repair shop or metal fabrication facility.

PDR (Paintless Dent Repair) for steel panels offers a revolutionary approach to damage restoration, providing both aesthetic and functional benefits. By understanding the simple yet effective process involved, professionals can deliver exceptional results while enhancing the value of steel structures. This non-invasive technique is a game-changer for various industries, ensuring swift repairs with minimal disruption, making PDR for steel panels an indispensable skill in today’s market.