Mercedes spot weld bonding is a cutting-edge technology that uses high-intensity laser beams to create permanent, precise bonds between metal car panels, revolutionizing vehicle repair and ensuring structural integrity without compromising performance. This method is a game-changer in the auto industry, offering unparalleled precision and efficiency for quicker repairs while maintaining top safety standards. Specialized welding techniques and bonding agents make it indispensable for preserving the structural integrity and safety of modern Mercedes Benz vehicles, enhancing rigidity, occupant protection during collisions, and overall vehicle performance after accidents.

Mercedes-Benz has pioneered an innovative technique, Mercedes spot weld bonding, that revolutionizes vehicle safety. This advanced method ensures the structural integrity of the safety cell without compromising performance. The article delves into the intricacies of this process, exploring its impact on overall vehicle safety and the unique techniques employed by Mercedes. By understanding Mercedes spot weld bonding, we gain insight into a game-changer in automotive engineering, enhancing both vehicle security and manufacturing efficiency.

- Understanding Mercedes Spot Weld Bonding: A Brief Overview

- The Impact of Spot Weld Bonding on Safety Cell Performance

- Advanced Techniques and Materials in Mercedes Spot Weld Bonding

Understanding Mercedes Spot Weld Bonding: A Brief Overview

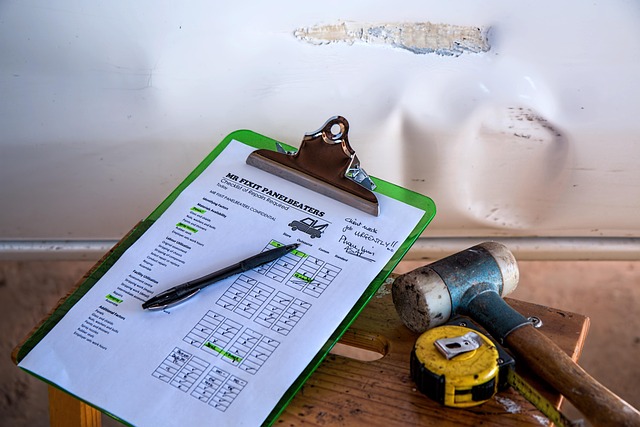

Mercedes spot weld bonding is a revolutionary technique that has transformed vehicle collision repair and car body restoration processes. This advanced method involves precisely applying high-intensity laser beams to create strong, permanent bonds between metal panels during car body repair. By focusing on specific points of contact, this technology ensures a solid fusion, enhancing the structural integrity of the safety cell without compromising its performance.

Unlike traditional bonding methods, Mercedes spot weld bonding offers unparalleled precision and efficiency. It allows for quicker car body restoration, ensuring that vehicles return to their pre-accident condition while maintaining optimal safety standards. This innovative approach has become a game-changer in the industry, setting new benchmarks for quality and reliability in vehicle collision repair.

The Impact of Spot Weld Bonding on Safety Cell Performance

Mercedes spot weld bonding plays a significant role in ensuring the structural integrity and safety of a vehicle, particularly in modern cars like Mercedes Benz models. The precision and strength of these spot welds directly contribute to how well the vehicle’s safety cell performs during collisions. When executed correctly, this technique enhances the overall rigidity of the car body, which is crucial for protecting occupants and maintaining the structural stability of the vehicle.

In the realm of vehicle repair and mercedes benz repair, proper spot weld bonding is indispensable. Car body shops skilled in this technique can effectively reinforce critical components, ensuring that even after an accident, the safety cell remains as robust as when the vehicle left the factory. This meticulous process not only preserves the structural integrity but also has a positive ripple effect on other aspects of the car’s performance and longevity.

Advanced Techniques and Materials in Mercedes Spot Weld Bonding

Mercedes spot weld bonding has evolved significantly, incorporating advanced techniques and materials that ensure superior safety cell performance. The process leverages modern metallurgy to create stronger, more durable bonds between vehicle components, enhancing structural integrity in case of collisions. One such technique is laser welding, which offers precise control over heat input, minimizing heat-related distortions and preserving the material’s properties.

Additionally, specialized bonding agents are used to augment the welds, providing extra strength and flexibility. These materials, designed for auto body repair and collision repair services, not only facilitate faster and more efficient assembly but also contribute to improved crash test ratings. The collision center’s adoption of these advanced practices underscores Mercedes’ commitment to delivering vehicles with unparalleled safety standards, ensuring that every component, down to the smallest weld, meets the highest industry requirements.

Mercedes spot weld bonding is a game-changer in automotive manufacturing, ensuring optimal safety cell performance without compromising structural integrity. By employing advanced techniques and high-quality materials, this innovative process maintains the strength and rigidity required for modern vehicles while enhancing overall safety standards. Understanding and implementing effective Mercedes spot weld bonding practices is crucial for automakers aiming to deliver top-tier, secure, and reliable vehicles.