Crashworthiness testing is a critical aspect of EV safety, particularly for iconic models like the Tesla Cybertruck, requiring specialized services due to its unique design. Regular repairs and maintenance are vital to prepare these vehicles for rigorous testing, addressing structural integrity, aesthetic restoration, and complex electric systems. Stricter quality standards and specialized tools ensure the Cybertruck maintains its safety features and distinctive look after accidents, emphasizing the importance of Tesla Cybertruck repair expertise.

In today’s digital era, electric vehicles like the Tesla Cybertruck are revolutionizing transportation. However, their unique design poses specific challenges in crashworthiness testing and subsequent repairs. This article delves into the crucial aspect of Tesla Cybertruck repair importance, exploring understanding crashworthiness for EVs, the vehicle’s distinctive safety hurdles, and best practices to ensure effective post-accident repairs. By examining these factors, we can emphasize the significance of robust repair procedures for the Cybertruck’s safety and reliability.

- Understanding Crashworthiness Testing for Electric Vehicles

- The Tesla Cybertruck's Unique Challenges in Repair and Safety

- Best Practices for Ensuring Effective Cybertruck Repairs After Accidents

Understanding Crashworthiness Testing for Electric Vehicles

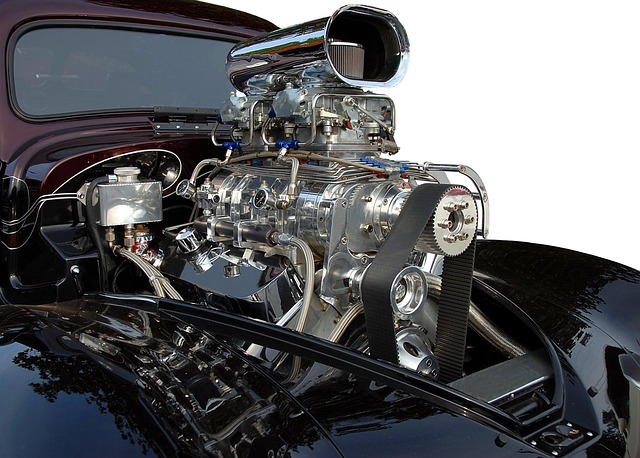

Crashworthiness testing is a critical aspect of evaluating the safety and structural integrity of electric vehicles (EVs), especially iconic models like the Tesla Cybertruck. As EV technology continues to advance, understanding how these vehicles perform in collisions becomes increasingly vital for both manufacturers and owners. Unlike traditional internal combustion engine cars, EVs have unique design considerations due to their battery packs and electric motors, making crashworthiness testing more complex.

The Tesla Cybertruck, with its distinctive look, needs rigorous auto repair services and thorough testing to ensure it meets safety standards. This includes simulations of various impact scenarios, from frontal collisions to side impacts, to assess the vehicle’s ability to protect occupants and minimize damage. Auto maintenance plays a significant role in preparing these electric vehicles for such tests, ensuring every component, from tires services to body panels, functions optimally under extreme conditions. Regular auto repair checks can identify potential vulnerabilities, allowing manufacturers to implement necessary improvements before mass production.

The Tesla Cybertruck's Unique Challenges in Repair and Safety

The Tesla Cybertruck presents unique challenges when it comes to crashworthiness testing and subsequent repairs compared to conventional vehicles. Its futuristic design, with its distinctive stainless-steel body and unconventionally shaped panels, introduces complexities in auto repair shops. The complex geometry of the exterior and interior components requires specialized collision repair services, including precise car paint repair techniques, to ensure structural integrity and aesthetic restoration after a collision.

Unlike traditional cars, the Cybertruck’s unconventional structure demands tailored approaches during the repair process. This includes managing the unique material properties of stainless steel, which can be challenging to weld and shape compared to more common metals used in modern vehicles. The high-tech nature of Tesla’s electric and autonomous systems further complicates repairs, necessitating advanced diagnostic tools and a deep understanding of the vehicle’s complex electronics for safe and effective collision repair services.

Best Practices for Ensuring Effective Cybertruck Repairs After Accidents

When it comes to the Tesla Cybertruck, ensuring effective repairs after accidents is paramount for maintaining its renowned crashworthiness. Best practices involve adhering to stringent quality standards and utilizing specialized tools designed for electric vehicle (EV) repair. Trained technicians should inspect every component of the car bodywork, from the frame to the battery system, to identify any damage or misalignments.

Effective collision repair services for the Cybertruck should encompass a comprehensive evaluation process. This includes using advanced diagnostic equipment to check for hidden damage and ensuring that all repairs meet original equipment manufacturer (OEM) specifications. By prioritizing these practices, owners can guarantee that their Cybertrucks not only look like new but also retain their superior safety features, making them reliable choices on the road.

The Tesla Cybertruck, with its innovative design, raises unique challenges in crashworthiness testing and subsequent repairs. As electric vehicles (EVs) gain popularity, understanding the importance of effective Cybertruck repairs is crucial for ensuring passenger safety. By adhering to best practices and staying informed about the latest repair techniques, technicians can navigate the specific complexities of this vehicle, ultimately contributing to a safer EV ecosystem. Effective Tesla Cybertruck repair processes are essential in mitigating risks and maintaining the structural integrity of these cutting-edge vehicles post-accidents.