Collision repair adhesives play a crucial role in vehicle safety, reconnecting damaged car parts to restore structural integrity. These specialized bonding agents must meet strict standards for strength, flexibility, and compatibility with various materials. Modern adhesives are designed to withstand high-stress areas, revolutionizing auto frame repair processes and enhancing safety ratings. Using high-grade collision repair adhesives is essential for auto body shops to guarantee reliable and safe car body repair services, aligning with evolving vehicle manufacturing technologies and environmental considerations. Future developments focus on integration with modern designs, quick application, faster setting times, and robust long-term performance, ensuring elevated safety ratings and maintaining aesthetic appeal in collision repair services.

Collision repair adhesives play a critical role in vehicle safety, enhancing structural integrity during crashes. This article delves into the intricate world of these adhesives and their profound impact on safety ratings. From understanding the fundamentals of their function to exploring the influence on crash test outcomes, we uncover how adhesive quality directly contributes to passenger protection. Additionally, we gaze into the future, where advanced collision repair adhesives promise to further revolutionize vehicle safety standards.

- Understanding Collision Repair Adhesives and Their Role in Vehicle Safety

- The Impact of Adhesive Quality on Crash Test Results

- Future Trends: Enhancing Safety with Advanced Collision Repair Adhesives

Understanding Collision Repair Adhesives and Their Role in Vehicle Safety

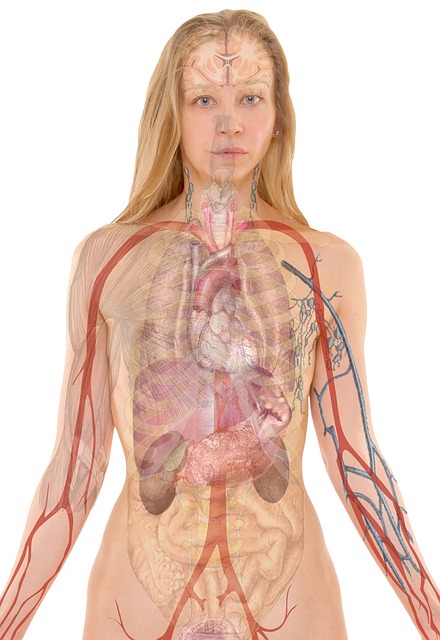

Collision repair adhesives play a pivotal role in ensuring vehicle safety during and after accidents. These specialized bonding agents are designed to reconnect damaged car parts, such as panels, frames, and components, restoring structural integrity. In the realm of car repair services, their application demands precision and adherence to strict standards to achieve optimal safety ratings.

Auto frame repair involves intricate work, and collision repair adhesives must meet specific criteria to maintain vehicle safety. The adhesive’s strength, flexibility, and compatibility with various materials are crucial factors. Modern adhesives are formulated to withstand high-stress areas, like the roof, doors, and fenders, ensuring they hold firm during sudden impacts. This is especially significant in collision repair, where the goal is not just to fix but also to enhance safety, often revolutionizing the way auto frame repairs are executed.

The Impact of Adhesive Quality on Crash Test Results

The quality of collision repair adhesives plays a pivotal role in the safety ratings of vehicles post-crash. Adhesives are a critical component in car body repair, ensuring structural integrity during and after impact. When a vehicle undergoes a crash test, the strength and durability of these adhesives can make or break the overall safety rating. High-quality adhesives provide robust bonding, contributing to the car’s ability to withstand forces generated in a collision, thereby enhancing passenger protection.

In the realm of auto body shops, using inferior adhesives can lead to structural failures during subsequent crash tests. This is because poor-quality adhesives may not hold up under stress, compromising the overall stability of the vehicle. Conversely, top-tier collision repair adhesives offer superior bonding power and flexibility, ensuring that car body repairs maintain their integrity even in challenging conditions. Thus, auto body shops should prioritize using high-grade adhesives to uphold safety standards and deliver reliable car body repair services.

Future Trends: Enhancing Safety with Advanced Collision Repair Adhesives

As technology advances, so too do the materials used in vehicle manufacturing and repair. Collision repair adhesives are evolving to meet higher safety standards, integrating advanced polymers and composites that offer enhanced structural integrity. These innovative adhesives not only improve crash performance but also contribute to lighter vehicle weights, thereby improving fuel efficiency and reducing environmental impact—a key trend in the automotive industry today.

Looking ahead, the future of collision repair adhesives lies in their ability to seamlessly integrate with modern vehicle designs, offering superior bonding strength while maintaining aesthetic appeal. With the increasing demand for quick and efficient bumper repair and collision repair services at auto collision centers, developers are focusing on formulations that can be applied quickly, set faster, and provide robust long-term performance. These advancements promise to elevate safety ratings even further, ensuring that vehicles not only withstand collisions but also maintain their structural integrity and passenger protection long after the incident.

Collision repair adhesives play a pivotal role in vehicle safety, significantly influencing crash test outcomes. As the automotive industry advances, focusing on enhanced safety and sustainability, future trends in collision repair adhesives will be instrumental. Developing advanced formulations that meet stringent performance criteria will ensure better structural integrity during collisions, ultimately protecting occupants and reducing severity of accidents. Continued research and innovation in this domain are essential to keep up with evolving safety standards, making our roads safer for all.