Snow-related crashes present unique challenges for drivers and automotive body shops due to reduced visibility, icy roads, and sudden weather changes, leading to various damage types. Efficient snow-related crash repair requires specialized techniques, a deep understanding of Original Equipment Manufacturer (OEM) guidelines, and expertise in frame straightening using advanced tools. Adhering to OEM standards ensures precise repairs, maintains structural integrity, preserves vehicle value, and guarantees safety and performance, making it crucial for high-quality restoration. For top results, follow a step-by-step guide: assess damage, use compliant tools and parts, clean affected areas, disassemble components, replace/repair body panels with exact techniques, inspect against OEM standards, and finish with quality paint matching the original finish. Complex cases may require a specialized auto collision center.

In regions with harsh winters, snow-related crashes pose unique challenges for automotive repairs. This article delves into the intricacies of snow-induced damage and emphasizes the significance of adhering to Original Equipment Manufacturer (OEM) guidelines for effective and safe restoration. We explore the steps involved in snow crash repair, ensuring precision and quality while addressing the specific requirements set by vehicle manufacturers. Understanding these guidelines is crucial for restoring vehicles to their pre-accident condition, enhancing safety, and minimizing long-term damage.

- Understanding Snow-Related Crashes and Their Unique Challenges

- The Role of Original Equipment Manufacturer (OEM) Guidelines in Crash Repair

- Step-by-Step Guide to Efficient and Safe Snow Crash Repair Adhering to OEM Standards

Understanding Snow-Related Crashes and Their Unique Challenges

Snow-related crashes present unique challenges for both drivers and automotive body shops. These incidents often occur due to reduced visibility, icy road conditions, and sudden changes in weather patterns. As a result, vehicles may suffer various types of damage, from minor car scratch repairs to more severe frame bending. The key difference between regular accidents and snow-related ones lies in the specific type of damage and the need for specialized techniques during repair.

For instance, icy roads can lead to skidding and sliding, causing impacts at odd angles, which may result in misaligned body panels or even cracked components. Therefore, efficient snow-related crash repair requires a deep understanding of original equipment manufacturer (OEM) guidelines. These guidelines ensure that repairs are not just cosmetic but also structural, maintaining the vehicle’s safety and performance standards. In an automotive body shop, professionals must be adept at frame straightening and utilizing advanced tools to address these challenges effectively.

The Role of Original Equipment Manufacturer (OEM) Guidelines in Crash Repair

In the intricate world of snow-related crash repair, adhering to Original Equipment Manufacturer (OEM) guidelines is paramount. These guidelines serve as a comprehensive blueprint, ensuring that repairs mirror the original vehicle design and performance. By following OEM standards, auto body shops deliver high-quality vehicle repair services that maintain safety and functionality. This meticulous process involves precise techniques for auto frame repair, aligning with the manufacturer’s specifications to restore the vehicle to its pre-accident condition.

OEM guidelines play a pivotal role in facilitating efficient and accurate vehicle repair. They provide detailed instructions on everything from replacement parts to specific procedures, ensuring every aspect of the crash repair meets the manufacturer’s rigorous standards. This level of adherence is crucial for not just restoring vehicles but also preserving their original value and reliability, which is especially important when dealing with snow-related incidents that can cause unique damage patterns.

Step-by-Step Guide to Efficient and Safe Snow Crash Repair Adhering to OEM Standards

When navigating through a snowy landscape, accidents can happen, leading to vehicle damage that requires meticulous repair. For efficient and safe snow-related crash repairs, adhering to Original Equipment Manufacturer (OEM) guidelines is paramount. Here’s a step-by-step guide to ensure top-notch results while maintaining safety standards.

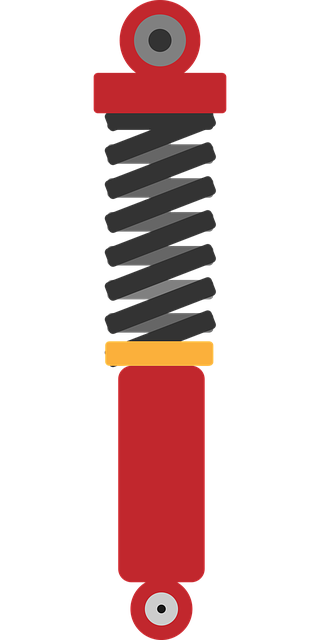

First, assess the extent of the damage, focusing on structural integrity. Next, gather all necessary tools and parts, ensuring they meet OEM specifications. Begin with a thorough cleaning of the affected areas to remove snow and ice debris. Then, carefully disassemble damaged components following the vehicle’s specific guidelines. Subsequent steps involve replacing or repairing parts like fenders, bumpers, and body panels, always referring back to OEM instructions for precise measurements and techniques. Finally, inspect the repair work, ensuring every detail aligns with OEM standards before completing the restoration with quality auto paint that matches the vehicle’s original finish. For complex cases, consider the services of a reputable auto collision center specializing in precision vehicle body repair.

In conclusion, navigating snow-related crashes requires a deep understanding of their unique challenges and adherence to Original Equipment Manufacturer (OEM) guidelines for effective and safe repairs. By following a step-by-step guide that aligns with these standards, technicians can ensure vehicle safety, performance, and longevity after such incidents, ultimately facilitating swift return to the road for affected drivers. This approach respects the OEM’s expertise and guarantees repairs meet the highest quality standards.