Specialty trim restoration is a meticulous process requiring precise techniques and strict environmental controls for both interior and exterior vehicle components. Controlled environments prevent damage like warping, cracking, or fading during drying and curing stages of painting and dent removal. Using air filtration systems, dehumidifiers, and heating/cooling units ensures optimal technician conditions and superior aesthetics in restored vehicles. Eco-friendly practices using low-VOC paints and efficient waste management set apart environmentally conscious restorers specializing in specialty trim repair.

Specialty trim restoration, involving the meticulous repair of intricate wooden or architectural details, demands precise environmental controls. This specialized craft requires a deep understanding of materials and techniques to ensure structural integrity while preserving historical significance. In this article, we explore the environmental considerations essential for safe and effective specialty trim repair, highlighting best practices for eco-friendly restoration methods. From material selection to workroom conditions, discover key strategies for successful, sustainable specialty trim restoration projects.

- Understanding Specialty Trim Restoration and Its Environmental Demands

- Essential Environmental Controls for Safe and Effective Repair

- Implementing Best Practices for Eco-Friendly Specialty Trim Restoration

Understanding Specialty Trim Restoration and Its Environmental Demands

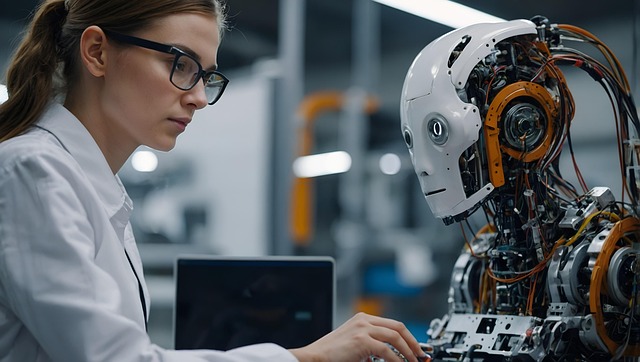

Specialty trim restoration is a meticulous process that involves the careful repair and replacement of intricate exterior and interior vehicle components. These can include door handles, grilles, bumpers, and other decorative elements that not only enhance a car’s aesthetic appeal but also contribute to its overall structural integrity. Understanding the nuances of specialty trim repair is essential given the environmental considerations unique to this specialized field.

The process demands precise techniques and specific environmental controls to ensure the longevity and quality of the restoration work. This often involves managing temperature, humidity, and air quality within a dedicated workspace, especially when dealing with materials like plastic, metal, and certain types of composite components. Maintaining these conditions is crucial, as they prevent warping, cracking, or fading of the restored trim pieces, particularly during the drying and curing stages of auto body painting and dent removal processes commonly found in collision repair centers.

Essential Environmental Controls for Safe and Effective Repair

When undertaking specialty trim repair, ensuring a controlled environment is paramount for both safety and the effectiveness of the restoration process. Proper environmental controls, including temperature regulation, humidity management, and dust suppression, are essential to prevent damage to delicate materials and ensure the longevity of the repair work.

In a vehicle body shop or during vehicle collision repair, maintaining specific conditions can be challenging due to the various materials and processes involved. For instance, high temperatures and elevated humidity levels can contribute to mold growth and warping on trim pieces, while dust from sanding or grinding operations can compromise the overall finish. Therefore, utilizing air filtration systems, dehumidifiers, and controlled heating/cooling units are vital components of a comprehensive body shop services regimen for specialty trim repair, ensuring both optimal working conditions for technicians and the best possible outcomes for the restored vehicle’s interior aesthetics.

Implementing Best Practices for Eco-Friendly Specialty Trim Restoration

In the realm of specialty trim restoration, adopting eco-friendly practices is not just a trend but a necessity to preserve our environment. When tackling intricate trim repairs, whether it’s for an old classic or a modern vehicle, restorers must implement best practices that minimize environmental impact. One key aspect is using sustainable materials and finishes whenever possible, opting for low-VOC (volatile organic compound) paints and adhesives that reduce air pollution. This approach aligns with the growing demand for eco-conscious automotive services, including bumper repair, auto collision repair, and vehicle dent repair.

Additionally, efficient waste management is a cornerstone of green specialty trim restoration. Restorers should strive to recycle or reuse materials where feasible, ensuring proper disposal protocols for any hazardous substances. By embracing these environmental controls, not only do restorers contribute to sustainability but also set themselves apart in the market. This commitment resonates with customers who prioritize eco-friendly solutions, especially when it comes to delicate trim repairs that require meticulous attention to detail.

Specialty trim restoration, while requiring precise craftsmanship, also demands thoughtful environmental controls. By implementing the essential measures and best practices discussed, professionals can ensure safe and effective repairs while minimizing ecological impact. These strategies are crucial for responsible specialty trim repair, balancing quality work with sustainability in today’s environmentally conscious world.