Spot welding equipment is a critical asset for collision repair shops, enabling precise and efficient fusion of metal surfaces with intense heat. Modern systems offer advanced controls, adjustable settings, and robust build quality, catering to diverse vehicle models and metal types. When selecting such equipment, prioritize safety features like overcurrent protection and automatic shut-off, alongside precision, reliability, and ease of use, to ensure top-notch repairs in the demanding automotive collision repair environment.

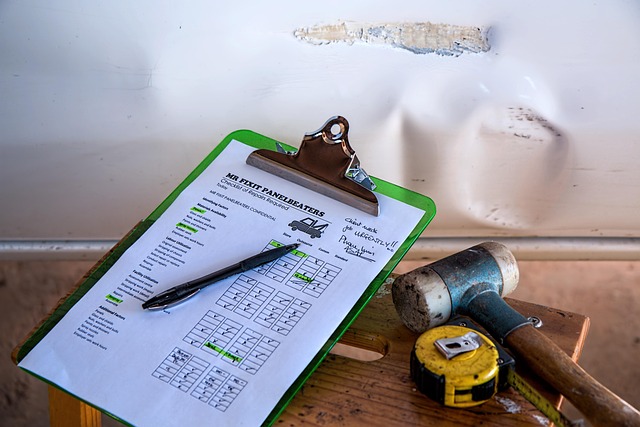

In the realm of collision repair, precision and efficiency are paramount. For certified collision centers aiming to deliver top-notch services, understanding the intricacies of spot welding equipment is crucial. This article delves into the essential requirements for effective spot welding, highlighting key features and specifications that set apart professional centers. From safety standards to operational efficiency, discover the factors driving the choice of spot welding equipment in today’s automotive industry.

- Understanding Spot Welding Equipment for Collision Repair

- Essential Features and Specifications for Certified Centers

- Safety and Efficiency Considerations in Choosing Equipment

Understanding Spot Welding Equipment for Collision Repair

Spot welding equipment plays a pivotal role in the precision and efficiency of collision repair processes within certified car body shops and automotive repair centers. This specialized machinery is designed to create robust bonds between metal panels, ensuring structural integrity during vehicle restoration. Understanding the capabilities and functions of spot welding equipment is essential for any collision repair center aiming to deliver high-quality, long-lasting repairs.

The core functionality of this equipment lies in its ability to focus intense heat onto specific points, melting and fusing metal surfaces together. This process allows for precise control over weld strength and quality, which is crucial for the structural stability of auto bodies. Modern spot welding systems offer advanced features such as variable power controls, digital display settings, and adjustable foot pedals, enabling automotive repair technicians to adapt to various metal types and thicknesses encountered in different vehicle models.

Essential Features and Specifications for Certified Centers

For certified collision centers aiming to deliver top-notch repairs, choosing the right spot welding equipment is paramount. Essential features include advanced control systems that offer precise temperature and current adjustments, ensuring consistent and high-quality welds across various metal types used in auto body painting and fender repair. These systems should support a range of welding techniques, from structural to cosmetic, allowing technicians to adapt to different automotive manufacturing standards.

Moreover, look for equipment with robust build quality capable of enduring the demanding environment of automotive collision repair. Easy-to-read displays, ergonomic designs, and safety features such as overcurrent protection and automatic shut-off mechanisms enhance operator comfort and minimize the risk of accidents during intensive welding sessions. The ability to integrate with other tools and a compatible power source is also beneficial for streamlined workshop operations.

Safety and Efficiency Considerations in Choosing Equipment

When selecting spot welding equipment for certified collision centers, safety and efficiency should be paramount considerations. These facilities handle delicate auto body restoration and car collision repair processes, demanding tools that combine precision and reliability. Investing in high-quality spot welding equipment not only ensures the integrity of repairs but also enhances productivity by streamlining work flows in these fast-paced environments.

Proper training and adherence to manufacturer guidelines are essential for safe operation. Features like automatic settings, adjustable parameters, and integrated safety mechanisms significantly reduce the risk of human error during auto collision repair. Additionally, versatile equipment capable of handling various metal types and thicknesses is crucial for tackling diverse repair scenarios in both structural and cosmetic auto body restoration projects.

For certified collision centers, investing in high-quality spot welding equipment is paramount. By understanding the specific requirements, considering safety and efficiency, and focusing on essential features and specifications, these facilities can ensure precise and reliable welds. The right spot welding equipment not only streamlines repair processes but also contributes to overall job satisfaction and vehicle restoration quality.