TIG welding collision systems are indispensable tools in auto body shops, utilizing Gas Metal Arc Welding (GMAW) technology to precisely repair vehicle bodies with minimal heat distortion. These systems ensure structural integrity and visual appeal after collisions, handling intricate repairs like paint and scratch restoration. By leveraging TIG techniques, they deliver top-tier results, reducing repair times, enhancing quality, and boosting vehicle longevity, making them a transformative force in automotive restoration.

TIG welding collision systems are transforming the landscape of automotive restoration. This advanced technique, utilizing Toxic Gas Welding (TIG), plays a pivotal role in ensuring vehicle integrity after collisions. By precisely fusing metal components, these systems restore structural strength and aesthetics, enhancing safety and vehicle value. The article delves into the science behind TIG welding, explores the intricate functionality of collision systems, and highlights the significant benefits it brings to modern automotive restoration practices.

- Understanding TIG Welding and Its Role in Collision Repair

- The Functionality of Collision Systems in Restoring Vehicle Integrity

- Benefits and Impact on Modern Automotive Restoration

Understanding TIG Welding and Its Role in Collision Repair

TIG welding, or Gas Metal Arc Welding (GMAW), is a precision welding process that uses a non-consumable tungsten electrode to join metals together. It’s a highly versatile technique used in various industries, including automotive and collision repair. In the context of vehicle body shops, TIG welding collision systems play a pivotal role in restoring crash integrity. This method allows for precise control over heat input, ensuring minimal heat distortion and preserving the structural integrity of the car’s frame and components.

When a vehicle suffers damage due to a collision, it’s crucial to restore not just the exterior but also the underlying structure. TIG welding systems enable expert auto detailers and body shop technicians to make intricate repairs with exceptional accuracy. By carefully applying heat and melting base metals together, these systems help create strong, lasting bonds that mimic the original manufacturing quality. This precision is particularly important in complex car paint repair and auto detailing tasks, ensuring not just visual appeal but also structural soundness.

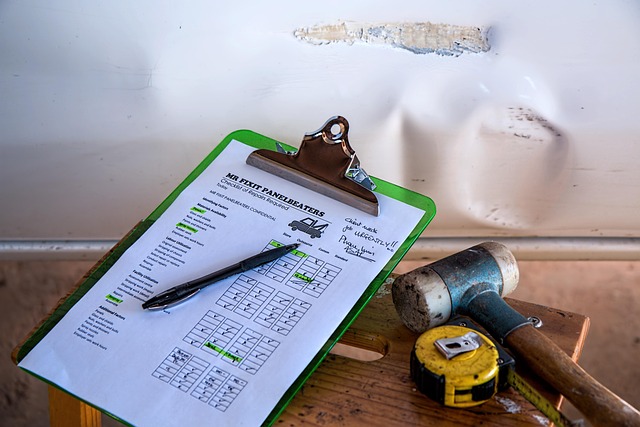

The Functionality of Collision Systems in Restoring Vehicle Integrity

TIG welding collision systems play a pivotal role in restoring crash integrity to vehicles, ensuring they are not just functional but also safe and aesthetically pleasing. These advanced systems employ TIG (Tungsten Inert Gas) welding techniques, known for their precision and strength, to repair damaged components. By precisely fusing metal parts together, the collision systems reestablish the structural integrity of the vehicle, preventing further deterioration or instability.

Moreover, these systems are particularly adept at handling intricate repairs, such as car paint repair and even car scratch repair. They meticulously mend not just the underlying metal but also restore the vehicle’s exterior, including its finish. This dual capability ensures that vehicles not only regain their structural integrity but also retain their aesthetic appeal, making them look as good as new on the road.

Benefits and Impact on Modern Automotive Restoration

TIG welding collision systems have emerged as a game-changer in modern automotive restoration, revolutionizing the way auto body shops handle crash repairs. These advanced systems offer numerous benefits, ensuring precise and efficient restorations. By employing TIG (Gas Metal Arc Welding) technology, auto repair services can achieve superior strength and structural integrity in repaired vehicles, meeting or exceeding manufacturer standards. This precision welding method allows for intricate joint configurations, enabling auto body services to restore complex vehicle panels with minimal distortion.

The impact of these systems on the automotive body shop is significant. They reduce the time required for repairs, minimizing downtime for vehicle owners. Moreover, TIG welding collision systems enhance the overall quality of auto body services, resulting in more robust and aesthetically pleasing finishes. This advanced technology ensures that restored vehicles not only perform optimally but also retain their original structural integrity, providing peace of mind for drivers and increasing the longevity of their vehicles.

TIG welding collision systems have emerged as indispensable tools in modern automotive restoration, playing a pivotal role in maintaining vehicle integrity after collisions. By understanding the unique capabilities of TIG welding and integrating advanced collision systems, restorers can achieve precise, durable repairs that match original manufacturing standards. These innovative approaches not only enhance safety but also contribute to the preservation of vehicles’ structural integrity, ensuring they return to the road with enhanced performance and reliability.