Advanced vehicle diagnostic tools and streamlined processes significantly optimize repair completion timelines in automotive service centers. By quickly identifying issues from engine problems to electrical malfunctions, technicians can efficiently plan and execute repairs, including frame straightening and auto painting. This reduces turnaround times, enhances customer satisfaction, and minimizes costs associated with prolonged vehicle downtime.

In today’s fast-paced automotive landscape, diagnostics play a pivotal role in optimizing the repair completion timeline. Understanding the intricate relationship between diagnostic tools and repair efficiency is key to enhancing service quality and customer satisfaction. This article delves into the significance of diagnostics, exploring their impact on repair speed and offering strategic insights for streamlining the process. By examining well-integrated diagnostic practices and implementing efficient strategies, auto shops can significantly reduce turnaround times.

- Understanding Diagnostics and Their Impact on Repair Efficiency

- Key Components of a Well-Integrated Diagnostic Process

- Strategies to Streamline Diagnostics for Faster Repair Completion

Understanding Diagnostics and Their Impact on Repair Efficiency

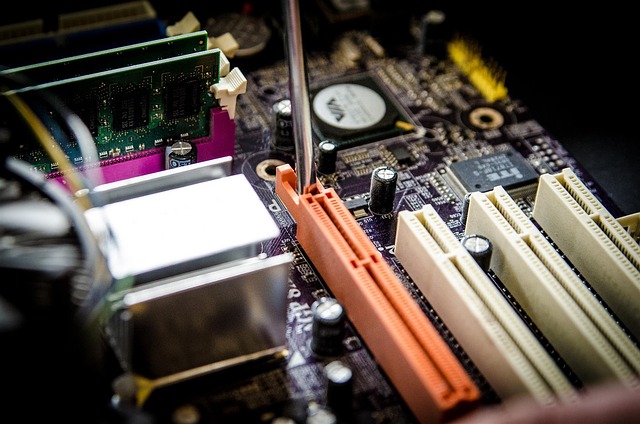

Diagnosing a vehicle’s issues is a critical step in determining the scope and complexity of repairs required. Advanced diagnostic tools used by auto repair shops today enable technicians to swiftly identify problems, which significantly impacts the repair completion timeline. These systems go beyond basic checks, delving into engine performance, electrical systems, and more, providing accurate insights into what needs fixing.

Efficient diagnostics translate into faster turnaround times for vehicle repair services, especially when it comes to specialized tasks like frame straightening. By quickly assessing damage, auto repair shops can implement the most effective strategies, ensuring repairs are completed promptly without compromising quality. This, in turn, enhances customer satisfaction and reduces costs associated with extended downtime.

Key Components of a Well-Integrated Diagnostic Process

A well-integrated diagnostic process is a cornerstone in streamlining the repair completion timeline for any automotive service centre. The key components include a thorough inspection, accurate damage assessment, and efficient data sharing between technicians and estimators.

Effective diagnostics begin with a meticulous examination of the vehicle to identify all damages, both visible and hidden. This involves the use of advanced equipment like digital measuring tools and 3D scanning technology for precise measurements and accurate restoration of the vehicle’s original state. Once damage is assessed, trained technicians can accurately determine the scope of work required, including frame straightening or auto painting services, ensuring a timely and high-quality repair completion timeline.

Strategies to Streamline Diagnostics for Faster Repair Completion

Streamlining diagnostics is a key strategy to expedite the repair completion timeline in automotive body shops, including those specializing in auto frame repair and car dent repair. By implementing efficient processes, technicians can significantly reduce the time spent on identifying and diagnosing issues. One effective approach is to utilize advanced diagnostic tools that provide accurate and rapid assessments of vehicle damage. These tools often employ sophisticated sensors and software algorithms to detect even subtle anomalies, enabling faster decision-making.

Additionally, establishing clear protocols for common repair scenarios can greatly enhance diagnostic efficiency. For instance, creating standardized checklists and step-by-step procedures for specific car dent repairs or auto frame adjustments ensures that every technician follows a consistent approach, minimizing the time spent on troubleshooting. Regular training sessions and knowledge-sharing among staff further contribute to faster diagnostics, as well-informed technicians can anticipate potential issues, leading to quicker turnarounds in the repair completion timeline.

Diagnostics play a pivotal role in optimizing the repair completion timeline. By integrating efficient diagnostic processes, repair shops can significantly enhance their efficiency and productivity. Understanding the impact of diagnostics and implementing streamlined strategies ensures faster turnaround times, satisfying customers, and staying competitive in today’s automotive industry. Key components like accurate testing, well-trained personnel, and advanced tools are essential to achieving this goal.