Modern repair equipment, driven by AI and advanced technology, is revolutionizing collision and auto repair centers. Sophisticated tools like robotic systems, CAD software, and laser cutting machines enhance efficiency and accuracy, minimizing errors in panel replacement and welding. Integration of AI algorithms predicts issues, recommends procedures, and suggests optimal parts, improving quality and longevity. Advanced scanning systems and digital interfaces enable faster diagnostics, real-time data sharing, and better troubleshooting for complex cases, ultimately elevating repair service standards.

Modern repair equipment is transforming the way we approach maintenance, offering unprecedented advancements that promise enhanced efficiency, increased safety, and improved reliability. Automation, AI, and sophisticated diagnostics are revolutionizing sectors from automotive to electronics. This article explores these breakthroughs, highlighting how time-saving features, ergonomic designs, and safety enhancements in modern repair equipment are driving productivity gains while fostering sustainable practices. Discover the profound impact of these innovations on the future of repairs.

- Advancements in Technology for Repairs

- – The role of automation and AI in modern repair equipment

- – Improved diagnostics capabilities and their benefits for technicians

Advancements in Technology for Repairs

The world of repairs has witnessed a significant transformation due to technological advancements, especially with modern repair equipment. Tools and machinery designed for car body repair and automotive collision repair have evolved to become more sophisticated and efficient. These innovations play a pivotal role in enhancing the precision and speed of work in collision centers.

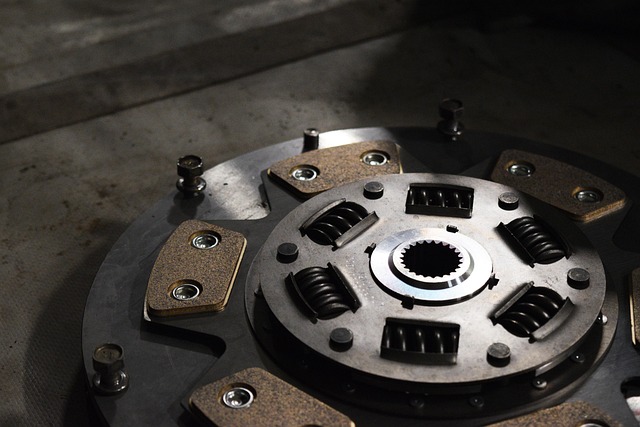

For instance, robotic systems are now employed in many advanced workshops, offering greater accuracy and consistency during panel replacement and welding processes. Similarly, computer-aided design (CAD) software allows technicians to plan and visualize repairs more effectively, ensuring complex jobs are completed with minimal errors. Additionally, the introduction of specialized equipment for modern repair techniques, such as laser cutting and precision measurement tools, has revolutionized the way collision centers operate, making car body repair processes faster and more reliable.

– The role of automation and AI in modern repair equipment

Modern repair equipment is transforming the landscape of both collision repair centers and auto repair shops, incorporating automation and artificial intelligence (AI) to streamline processes and enhance precision. These advanced technologies play a pivotal role in revolutionizing car damage repair by offering unprecedented efficiency and accuracy. Automation takes over repetitive tasks, such as panel bending and painting, using robotic arms that guarantee consistent results, thereby reducing the risk of human error.

AI algorithms analyze complex data sets, enabling technicians to make informed decisions during repairs. These systems can identify and predict potential issues, recommend specific repair procedures, and even suggest optimal replacement parts for various makes and models. By leveraging automation and AI, modern repair equipment not only improves productivity in auto repair shops but also ensures superior quality and longevity in collision repair center operations.

– Improved diagnostics capabilities and their benefits for technicians

Modern repair equipment has significantly elevated the diagnostic capabilities of technicians, enabling them to pinpoint issues with greater precision and speed. These advancements are driven by sophisticated technology that goes beyond traditional methods. For instance, modern tools often incorporate AI-powered sensors and advanced scanning systems that can detect subtle anomalies in vehicle systems, from engine performance to electrical networks. This improved diagnostics offers numerous benefits for both technicians and customers. Technicians spend less time troubleshooting and more time providing effective solutions, leading to faster turnaround times for repairs. Customers benefit from more accurate assessments, reduced costs, and improved vehicle reliability.

Furthermore, the integration of digital interfaces allows for real-time data sharing between technicians and manufacturers, ensuring access to the latest service information and repair procedures. This exchange facilitates efficient troubleshooting, especially in complex cases involving car bodywork or dent removal. Modern equipment thus not only enhances the accuracy and efficiency of repairs but also keeps technicians well-informed about evolving vehicle technologies, ultimately elevating the standards of vehicle repair services.

Modern repair equipment, driven by advancements in automation, AI, and improved diagnostics, is revolutionizing the repairs industry. These innovations not only enhance efficiency but also empower technicians with better insights, reducing downtime and improving overall job quality. As technology continues to evolve, we can expect even more sophisticated tools that will further streamline repair processes, making them faster, more precise, and environmentally friendly. Embracing these changes ensures that both professionals and consumers benefit from a repaired product that meets the highest standards of today’s digital era.