The traditional collision repair process struggles with accuracy due to manual measurements and visual assessments, especially in complex modern vehicles. 3D vehicle scanning emerges as a revolutionary solution by providing precise digital representations of damaged cars, enhancing repair planning and execution for increased efficiency and effectiveness. This technology is particularly beneficial for tire services and bumper repair, ensuring optimal alignment and functionality.

The collision repair process, long plagued by time-consuming manual measurements and intricate adjustments, is undergoing a transformative revolution. Traditional methods, known for their error-prone nature and lengthy timelines, are being superseded by an innovative solution: 3D vehicle scanning. This cutting-edge technology promises to redefine the industry by offering unparalleled precision, efficiency, and accuracy in repair work. By capturing detailed 3D data of damaged vehicles, repair teams can navigate complex repairs with enhanced confidence, ultimately leading to improved structural integrity, faster turnaround times, higher quality outcomes, and greater customer satisfaction.

- The Current State of Collision Repair and Its Challenges

- – Overview of traditional methods and their limitations

- – Time-consuming and error-prone processes

The Current State of Collision Repair and Its Challenges

The current collision repair process involves manual measurements and visual assessments, which can lead to inaccuracies and inconsistencies. This is particularly challenging when dealing with complex vehicle designs and extensive damage. Traditional methods often rely on experience and estimation, resulting in varying levels of quality and efficiency across collision centers. The process is further complicated by the need for precise fitting of parts, especially in modern vehicles with intricate systems and advanced safety features.

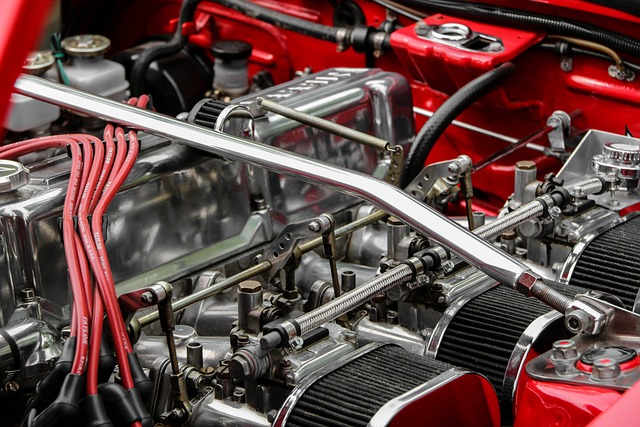

Moreover, tire services and bumper repair, two critical aspects of collision repair, require exact measurements to ensure proper alignment and functionality. Without advanced technology, achieving these levels of precision can be time-consuming and prone to errors. 3D vehicle scanning is transforming this landscape by providing a detailed digital representation of the damaged vehicle, enabling technicians to plan repairs with enhanced accuracy and efficiency.

– Overview of traditional methods and their limitations

The traditional collision repair process has relied on manual measurements and estimates for decades. This often involves using calipers to take precise measurements of damaged areas, which are then inputted into a 2D drawing or computer-aided design (CAD) software. While this method has served the industry well, it comes with several limitations. One significant drawback is the potential for human error; even the most skilled technicians can make mistakes when taking measurements by hand, leading to inaccurate repairs and inconsistent results.

Furthermore, traditional methods struggle to capture the complex geometry of modern vehicle designs. Today’s cars are more intricate, with curved surfaces, intricate panels, and diverse material finishes. These complexities often require specialized tools and techniques for repair, such as paintless dent repair for minor dents and scratches or precise tire services to ensure proper alignment. 3D vehicle scanning offers a revolutionary solution by providing an accurate, digital representation of the damaged vehicle’s bodywork, enabling more efficient, effective, and precise collision repairs.

– Time-consuming and error-prone processes

In the traditional collision repair process, assessing and documenting vehicle damage was often a time-consuming and error-prone endeavor. Without the advanced technology of 3D vehicle scanning, technicians relied on manual measurements and visual inspections, leading to potential inaccuracies and delays. This method could result in misjudged repairs, particularly for complex car dent repairs or extensive auto body work, causing further complications and longer turnaround times.

With 3D scanning, the industry has a powerful tool to streamline these processes. By capturing detailed digital representations of damaged vehicles, 3D scanning technology enables precise measurements and analysis, ensuring more accurate assessments. This innovation is particularly beneficial for car bodywork services, as it facilitates efficient planning and execution of repairs, ultimately reducing the time and resources required for auto body work.

3D vehicle scanning is revolutionizing collision repair by offering a faster, more precise alternative to traditional methods. By capturing detailed digital models of damaged vehicles, this technology streamlines the estimation and repair process, reducing human error and improving overall efficiency. As the automotive industry continues to evolve, adopting 3D scanning will be key in maintaining high standards and customer satisfaction within the collision repair sector.