Surface preparation is key to achieving high-quality results with polishing techniques on aluminum or steel panels. This involves cleaning, sanding, and deburring to remove contaminants and irregularities, creating a clean base for effective bonding of polish compound. Proper degreasing and cleaning with mild detergent, specialized cleaners, and degreasing agents are essential steps before polishing, ensuring a smooth, glossy finish that extends the lifespan of the polish.

“Unleash the radiance hidden in your aluminum and steel panels with expert polishing techniques. This comprehensive guide dives into the art of surface preparation, from the crucial steps of degreasing and sanding to choosing the perfect polishing agents and tools.

Learn how chemical and mechanical compounds work their magic, select the right cloths, pads, and wheels, and master a step-by-step process for achieving everything from a subtle matte finish to a breathtaking mirror-like shine. Perfect for professionals and enthusiasts alike, this article is your ultimate resource for mastering polishing techniques.”

- Understanding the Surface Preparation for Polishing

- – The importance of surface cleanliness and smoothness

- – Methods for degreasing and cleaning aluminum and steel panels

Understanding the Surface Preparation for Polishing

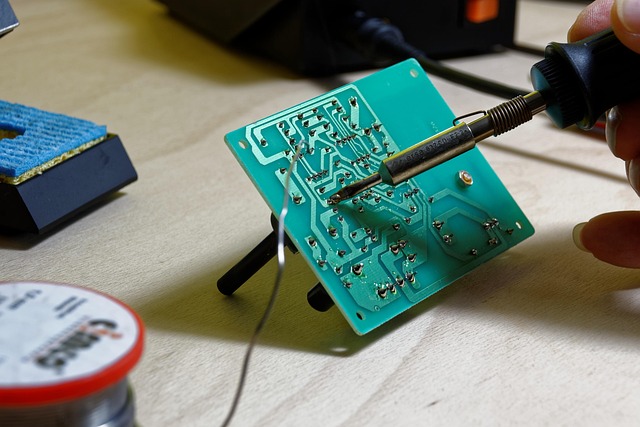

Before diving into any polishing techniques for aluminum or steel panels, it’s crucial to grasp the importance of surface preparation. The initial steps in the process are akin to laying a solid foundation—they ensure that your final polish is not only effective but also lasting. In auto bodywork, where precision and aesthetics matter, understanding this step becomes even more critical.

For aluminum and steel panels, whether used in automotive collision repair or for auto body painting, surface preparation involves cleaning the surface thoroughly to remove any contaminants, followed by sanding and deburring to smooth out irregularities. This process creates a clean canvas that allows the polishing compound to bond effectively, resulting in a gleaming, professional finish. Effective surface preparation not only enhances the visual appeal but also prolongs the life of the polish, making it an indispensable step in any automotive refining or restoration project.

– The importance of surface cleanliness and smoothness

Maintaining a pristine surface is paramount when it comes to polishing aluminum and steel panels, whether for automotive applications in a collision repair shop or enhancing industrial panels. A clean and smooth base is essential as it ensures that the polish adheres evenly, creating a lustrous finish. Any existing contaminants, such as dirt, grease, or oxidation, can hinder the effectiveness of polishing techniques, resulting in an uneven or lackluster appearance.

In the car body shop, achieving surface cleanliness involves meticulous prep work, including washing, degreasing, and using specialized cleaning solutions to remove stubborn residues. For steel panels, a mild etching process might be employed to create a slightly roughened surface that enhances polish retention. In contrast, aluminum surfaces often require more delicate treatment due to their tendency to attract water spots and fingerprints, necessitating the use of non-abrasive cleaners and microfiber cloths for optimal preparation before applying polishing techniques.

– Methods for degreasing and cleaning aluminum and steel panels

Before applying any polishing techniques to aluminum or steel panels, proper degreasing and cleaning are essential steps. Start by removing any surface contaminants using a mild detergent and warm water solution. This initial wash ensures that no grease, dirt, or dust particles remain on the panel’s surface, which could hinder the polishing process. For stubborn stains or residue, you can use specialized cleaner solutions designed for automotive applications, often found in car paint services and auto collision repair shops.

Once the panels are clean, a degreasing agent is applied to dissolve any remaining oils and grease. This step is crucial, especially when dealing with car body repair, as it prepares the metal surface for polishing, ensuring a smooth and glossy finish. After applying the degreaser, allow it to sit for the recommended time, then thoroughly rinse with clean water. This process leaves the aluminum or steel panels ready for the next stage of preparation in your chosen polishing techniques.

Polishing aluminum and steel panels requires a meticulous approach, beginning with proper surface preparation. Achieving pristine cleanliness and smoothness is paramount, as it lays the foundation for effective polishing techniques. By employing suitable degreasing and cleaning methods, you can ensure a durable and glossy finish that enhances the aesthetic appeal of both residential and commercial installations. Mastery of these techniques promises outstanding results, transforming raw panels into stunning, reflective surfaces.