Tesla prioritizes unparalleled repair quality control, a hallmark of its commitment to excellence. The process involves rigorous inspections, advanced diagnostics, thorough part examination, and meticulous training for technicians, ensuring repaired vehicles meet the brand's high standards. This data-driven approach, focusing on KPIs like defect rate and customer satisfaction, guarantees precise repairs with seamless performance and structural integrity, distinguishing Tesla in the industry.

Tesla’s commitment to exceptional vehicle quality is renowned, and a significant aspect of this is its rigorous repair quality control process. This comprehensive guide delves into the step-by-step procedure that ensures every Tesla repair meets stringent standards. From initial diagnostics to final testing, we explore how Tesla maintains its reputation for superior craftsmanship. Understanding the key performance indicators and implementing consistent repair practices across the board is vital to this success. Uncover the secrets behind Tesla’s efficient and effective quality control system.

- Understanding Tesla's Quality Control Standards

- – Overview of Tesla's commitment to quality

- – Key performance indicators and benchmarks

Understanding Tesla's Quality Control Standards

Tesla is renowned for its stringent quality control standards across all aspects of its operations, and this extends to its vehicle repair services. The company sets high bars for itself and its network of authorized collision repair shops, ensuring that every car leaving their facilities meets or exceeds original equipment manufacturer (OEM) specifications. This commitment to excellence is embedded in Tesla’s DNA, fostering a culture where precision and craftsmanship are paramount.

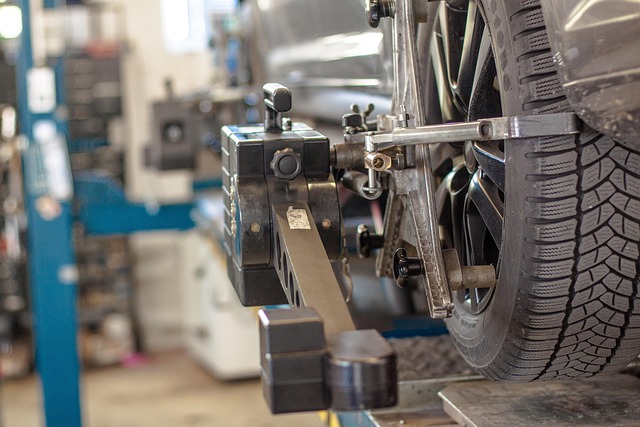

The Tesla repair quality control process begins with rigorous inspections at each stage of the repair journey. Trained technicians meticulously assess damage, utilizing advanced diagnostic tools to identify components requiring replacement or repair. From there, every part used in the collision repair shop is scrutinized for authenticity and performance, ensuring it meets Tesla’s stringent criteria. This meticulous approach guarantees that the finished vehicle not only looks like new but also performs as such, upholding the brand’s reputation for superior quality across all vehicle repair services.

– Overview of Tesla's commitment to quality

Tesla is renowned for its innovative technology and commitment to excellence, extending far beyond its electric vehicles. When it comes to Tesla repair quality control, the company sets remarkably high standards. Every step of the process, from initial assessment to final inspection, is meticulously designed to ensure that repairs match the brand’s impeccable reputation.

The focus on quality begins with rigorous training for technicians. They are equipped with expertise in the latest repair techniques and technology specific to Tesla vehicles. This specialized knowledge ensures that every auto body work or car body restoration is carried out with precision and care, upholding Tesla’s commitment to safety and performance. The company’s unwavering dedication to quality control is a key differentiator, setting them apart from conventional auto repair shops.

– Key performance indicators and benchmarks

Tesla’s repair quality control process is meticulously designed to ensure every vehicle that leaves their facility meets the highest standards. Key performance indicators (KPIs) like defect rate, customer satisfaction scores, and repair time are benchmarked against industry leaders. These metrics provide a clear picture of the auto body shop’s performance, highlighting areas for improvement and confirming consistent quality in collision repair services. By focusing on these KPIs, Tesla aims to deliver top-notch car scratch repairs that match the brand’s reputation for innovation and excellence.

The quality control process starts with rigorous inspections at every stage of the repair, from initial assessment to final checkout. Specialized teams use advanced tools and techniques to ensure precise panel fitting, paint consistency, and structural integrity. This meticulous approach extends beyond visible repairs, encompassing hidden components and systems as well. Regular training sessions equip technicians with the latest knowledge in auto body repair, ensuring they stay up-to-date with industry best practices, thereby enhancing the overall quality of collision repair services provided.

Tesla’s rigorous repair quality control process ensures that every vehicle returned to its owners meets the brand’s high standards. From initial inspection to final sign-off, each step is meticulously executed by certified technicians using state-of-the-art equipment and genuine Tesla parts. This commitment to excellence guarantees not only the superior performance of repaired vehicles but also reinforces Tesla’s reputation for unparalleled customer satisfaction in the automotive industry.