The Tesla Measure System, an advanced technology integrated into Tesla vehicles, leverages sensors and cameras to accurately map vehicle dimensions, revolutionizing auto body restoration and repair. This system enhances efficiency, quality control, and speed in repairs, ultimately boosting customer satisfaction. It joins a diverse yet rapidly evolving measurement tech landscape, including 3D scanning, laser measuring, and CAD software, with applications across industries, especially automotive. While facing challenges like reflective surfaces and workshop calibration, the Tesla Measure System's strengths indicate its potential to transform auto maintenance practices.

The Tesla Measure System, a cornerstone of modern electric vehicle (EV) technology, is poised for significant advancements. Currently, this system relies on advanced sensors and data analytics for crucial safety features like autonomous driving and obstacle detection. However, upcoming updates promise to elevate its capabilities through artificial intelligence (AI), improved sensor accuracy, and real-time data visualization. These innovations will not only enhance vehicle performance but also open doors to broader industrial and consumer applications, revolutionizing how we interact with technology in our daily lives.

- Current Capabilities of Tesla Measure System

- – Overview of current measurement technologies and applications

- – Strengths and limitations of the existing system

Current Capabilities of Tesla Measure System

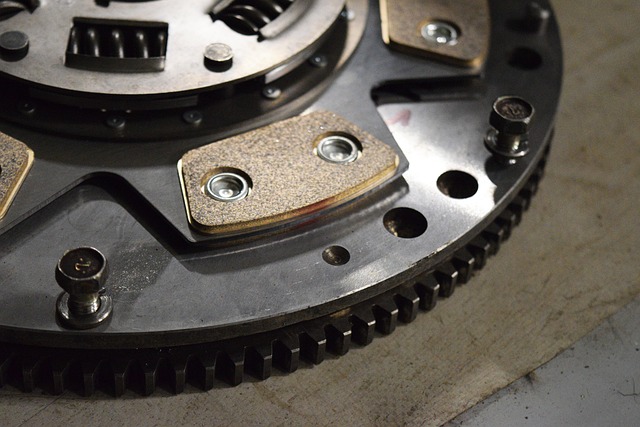

The Tesla Measure System, a cutting-edge technology integrated into Tesla vehicles, currently stands as a testament to the company’s commitment to innovation and precision engineering. This system leverages advanced sensors and cameras to accurately gauge dimensions, ensuring flawless integration during auto body restoration or bodywork repairs. By mapping the vehicle’s exterior with unparalleled detail, it facilitates seamless replacement parts installation, be it for minor scuffs or major accidents, enhancing the efficiency of vehicle paint repair processes.

In terms of functionality, the Tesla Measure System provides real-time data on panel gaps, curvature, and other critical parameters, setting a new standard in quality control. This technology not only streamlines service centers’ operations but also promises enhanced customer satisfaction through more accurate and swift auto bodywork repairs, ensuring vehicles return to their optimal condition faster than ever before.

– Overview of current measurement technologies and applications

The current landscape of measurement technologies is a diverse and evolving field, with applications spanning various industries. In the automotive sector, precision measurements are paramount for everything from manufacturing components to ensuring safe and efficient vehicle operation. Technologies like 3D scanning, laser measuring tools, and computer-aided design (CAD) software have revolutionized auto body work and collision repair services, enabling precise reconstruction and restoration of damaged vehicles. These digital measurement methods not only streamline the repair process but also enhance the accuracy of auto dent repair, resulting in superior outcomes.

The Tesla measure system, as an emerging innovation, aims to integrate these advanced measurement techniques into a comprehensive suite tailored for electric vehicle (EV) manufacturing and maintenance. By leveraging cutting-edge sensors and data analytics, this system promises to streamline production processes, improve quality control, and optimize repair procedures, particularly in the realm of EV-specific auto body work. This evolution in measurement technologies is poised to drive efficiency gains and further elevate the standards in collision repair services, making it an exciting development for both industry professionals and consumers alike.

– Strengths and limitations of the existing system

The current Tesla measure system has proven to be a game-changer for vehicle repair and auto maintenance, offering precise measurements that enhance the accuracy of repairs. Its strengths lie in providing real-time data, allowing technicians to quickly assess damage and make informed decisions during auto painting and other intricate processes. This level of precision is invaluable, especially when dealing with complex components.

However, the system isn’t without limitations. It may struggle with highly reflective or transparent surfaces, which can affect measurement accuracy. Additionally, in bustling workshops where multiple tasks are ongoing, ensuring consistent calibration and maintaining optimal conditions can be challenging. Despite these setbacks, the Tesla measure system’s capabilities highlight its potential to revolutionize auto maintenance practices, paving the way for even more advanced technologies in the future.

As we look ahead, the future of the Tesla measure system promises exciting advancements. By leveraging cutting-edge technologies, these updates will enhance measurement accuracy, expand application ranges, and address current limitations. Such improvements are set to revolutionize various industries that rely on precise and efficient data collection, solidifying the Tesla measure system’s position as a game-changer in the market.