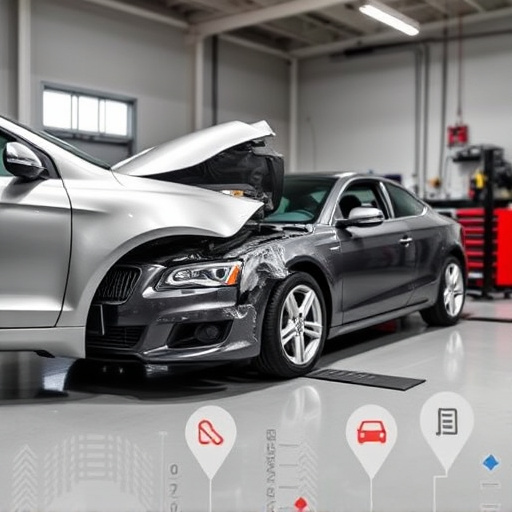

Seam sealer application is crucial after replacing car panels, offering both structural support and aesthetic enhancement. By preventing water intrusion and corrosion, it strengthens repairs and maintains vehicle value. The process involves cleaning surfaces, selecting compatible seam sealers based on weather and material type, applying a thin layer along joints, and smoothing excess for long-lasting, professional results that protect against future damage.

After replacing damaged or old panels, applying a high-quality seam sealer is essential for maintaining a durable and water-tight finish. This article guides you through the process of seamless panel replacement by detailing where and how to apply seam sealer effectively. We’ll explore the crucial role of seam sealers, identify suitable panel types, and provide a step-by-step guide ensuring your new panels stay protected. Optimize your repair efforts with these essential insights into seam sealer application.

- Understanding Seam Sealer: Its Role and Benefits After Panel Replacement

- Identifying the Right Panels for Seam Sealer Application

- Step-by-Step Guide to Applying Seam Sealer Effectively

Understanding Seam Sealer: Its Role and Benefits After Panel Replacement

Seam sealer application plays a pivotal role in the post-panel replacement process, offering significant advantages for both structural integrity and aesthetic appeal. After replacing a panel, whether on a car, bumper, or other automotive components, applying seam sealer is essential. This substance creates a robust bond between adjacent panels, preventing water intrusion and corrosion, which can compromise the integrity of the repair over time.

Not only does it reinforce the structural strength of the replacement, but a proper seam sealer application also enhances the overall look of the repaired area. By filling in gaps and smoothing out seams, it conceals evidence of previous damage, such as car dents or bumper repairs, contributing to a seamless, professional finish akin to auto detailing. This is particularly crucial for maintaining the vehicle’s value and ensuring it looks its best on the road.

Identifying the Right Panels for Seam Sealer Application

When replacing panels in auto body work or car body repair, it’s crucial to choose the right panels for seamless integration and long-lasting results. The suitability of a panel for seam sealer application depends on its material, condition, and compatibility with your vehicle’s make and model. For instance, while steel panels are common and easily welded, they may require specific sealants due to their properties. Aluminum or composite panels, often found in modern vehicles, demand different techniques and products, such as high-performance adhesives or sealers designed for these materials.

Proper preparation is key; damaged or contaminated surfaces must be thoroughly cleaned and decontaminated before applying any sealant. This includes removing any debris, dust, or old adhesive residues that could interfere with the bond strength of your chosen seam sealer. By matching the panel to your vehicle’s specific needs and ensuring optimal surface conditions, you’ll achieve a robust and durable finish during the auto body services process, enhancing the overall quality of the repair.

Step-by-Step Guide to Applying Seam Sealer Effectively

Applying seam sealer effectively after replacing a panel is a crucial step in ensuring your car’s structural integrity and aesthetics. Start by preparing the surface thoroughly; clean any debris or dust from the joint area using a soft cloth or brush. This ensures the sealer adheres properly. Next, choose the right type of seam sealer suitable for automotive applications, considering factors like weather conditions and material compatibility.

Follow a step-by-step process: first, apply a thin layer of sealer along the joint’s entire length, pressing it into the gap. Allow the sealer to set slightly, then use a smooth, dry cloth to remove any excess. Ensure complete coverage without gaps or overlaps. For curved surfaces or complex joints, consider using a tool designed for seam sealer application to achieve precise results. Remember, a well-applied seam sealer is key in auto glass repair and car bodywork maintenance, preventing water intrusion and corrosion.

When replacing panels, especially in exterior settings, proper seam sealer application is vital for maintaining structural integrity and protecting against moisture intrusion. By understanding the benefits of seam sealers and selecting the right panels, followed by a meticulous step-by-step guide, you can ensure your replacement project creates a durable, weatherproof finish. Remember, the key to successful seam sealer application lies in preparation and adherence to best practices.