Seized bolts cause significant delays and safety risks across diverse sectors. Induction heating systems offer a revolutionary solution by using electromagnetic induction to safely and quickly loosen corroded or over-tightened bolts without damaging components. This non-destructive approach is especially valuable in auto maintenance and restoration, where precision is key. Compared to conventional methods, induction heating provides a more efficient, cost-effective, and precise way to tackle seized bolts effectively, transforming automotive repairs and minimizing damage risk during various dent repairs.

Seized bolts can cause significant headaches in maintenance and repair tasks, often leading to expensive downtime. Induction heating systems offer a powerful solution, effectively unseating stubborn bolts without damaging surrounding components. This article delves into the science behind induction heating, exploring how it tackles seized bolts and its numerous advantages in various applications. By understanding these benefits, professionals can leverage induction heating for efficient, precise bolt removal.

- Understanding Seized Bolts and Their Impact

- The Role of Induction Heating Systems in Unseating Seized Bolts

- Advantages and Applications of Induction Heating for Bolt Removal

Understanding Seized Bolts and Their Impact

Seized bolts are a common issue that can arise in various settings, from industrial manufacturing to auto collision repair and car restoration projects. These bolts, designed to hold components together, can become tightly fastened due to factors like rust, corrosion, or over-tightening, rendering them nearly impossible to remove with conventional tools. The impact of seized bolts is significant, leading to costly downtime in auto maintenance and potential safety risks if left unresolved. In critical applications like automotive engineering, where precision and efficiency are paramount, this problem demands a swift and effective solution.

Induction heating systems have emerged as a powerful tool in the fight against seized bolts. By using targeted heat generated by electromagnetic induction, these systems can quickly and safely loosen corroded or tightly fastened bolts, making them easier to remove without causing further damage. This non-destructive approach is particularly beneficial in auto maintenance and car restoration, where preserving the integrity of components is crucial. Compared to traditional methods that might lead to excessive force and potential part failure, induction heating offers a more precise, efficient, and cost-effective solution for tackling seized bolts.

The Role of Induction Heating Systems in Unseating Seized Bolts

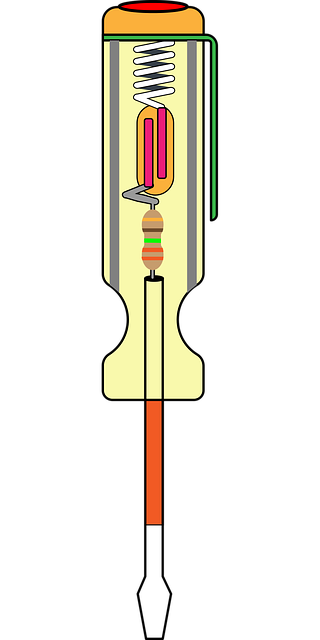

Induction heating systems play a pivotal role in the world of automotive repairs, particularly when it comes to addressing seized bolts. These innovative systems have revolutionized the way mechanics tackle stubborn fastenings that have become immobile due to corrosion, wear, or impact damage. By utilizing electromagnetic energy, induction heaters can generate intense heat within the bolt, causing the metal to expand and loosen its grip, essentially unseating the bolt without the need for excessive force.

For Mercedes-Benz repair specialists and collision repair centers dealing with various vehicle dent repairs, this technology is a game-changer. It offers a precise, efficient, and non-destructive method of removing seized bolts, minimizing the risk of further damage to the surrounding components. Unlike traditional methods that might involve hammering or heavy mechanical force, induction heating systems provide a gentle yet powerful solution, making them ideal for delicate repair procedures, whether it’s unseating a stubborn wheel bolt or disassembling complex vehicle frameworks.

Advantages and Applications of Induction Heating for Bolt Removal

Induction heating systems offer several advantages when it comes to removing seized bolts, making them a popular choice in various industries, including vehicle collision repair. These advanced technologies provide a non-contact and highly precise heating method, which is particularly useful for hard-to-reach areas. Unlike traditional methods that rely on direct contact or harsh chemicals, induction heating gently heats the bolt, expanding the metal and breaking the seizure without causing damage to the surrounding components. This not only streamlines the disassembly process but also ensures the integrity of delicate parts, especially in fender repair services.

The versatility of induction heating systems makes them applicable in numerous scenarios, from heavy machinery maintenance to automotive body shop operations. For instance, when dealing with collision-damaged vehicles, induction heating can quickly and safely loosen severely corroded or seized bolts, facilitating faster and more efficient repairs. This technology’s ability to target specific areas ensures minimal heat distortion, preserving the overall quality of replacement parts and reducing the need for costly rework in fender repair processes.

Induction heating systems have proven to be invaluable tools for removing seized bolts, offering a fast, efficient, and non-destructive solution. By leveraging electromagnetic energy, these systems safely and effectively unseat bolts that traditional methods struggle with, making them essential in various industries where quick and reliable bolt removal is crucial. The advantages of induction heating for bolt removal are clear, solidifying its position as a game-changer in navigating stubborn fasteners.