In molding replacement collision, fit and finish are key to ensuring structural soundness and aesthetic appeal. Auto body repair professionals employ advanced techniques like frame straightening and scratch repair to achieve precise alignment and smoothness. Best practices include meticulous surface preparation, high-quality primer and paint, and techniques like sandblasting or wet sanding for a seamless, factory-like finish that enhances both functionality and resale value, meeting modern consumers' expectations in collision repair.

The precision and quality of fit and finish in molding replacement collision are paramount in modern automotive repair. This crucial aspect ensures not only structural integrity but also enhances safety, preserves aesthetics, and extends vehicle lifespan. A seamless blend of material expertise, skilled craftsmanship, and advanced technologies is required to achieve superior results. This article delves into the fundamentals of fit and finish, highlights its significant impact, and provides best practices for achieving exceptional standards in automotive repairs involving molding replacement collision.

- Understanding Fit and Finish: The Foundation of Quality in Molding Replacement Collision

- Why Precision Matters: Impact on Safety, Aesthetics, and Longevity

- Best Practices for Achieving Superior Fit and Finish in Automotive Repairs

Understanding Fit and Finish: The Foundation of Quality in Molding Replacement Collision

Understanding Fit and Finish: The Foundation of Quality in Molding Replacement Collision

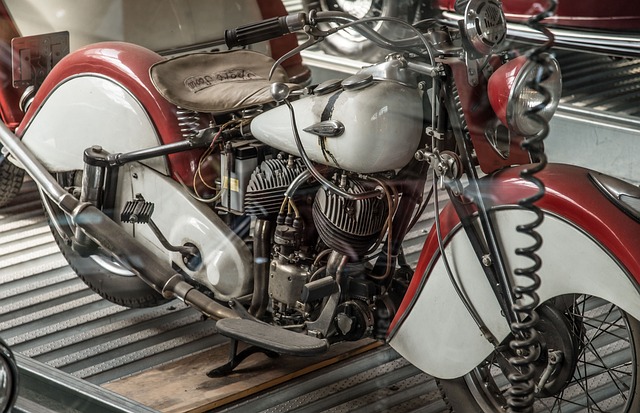

Fit and finish refer to the precise alignment and smoothness of surfaces in an automobile, particularly after collision repair or replacement. In the context of molding replacement collision, it is a critical aspect that ensures not just structural integrity but also aesthetic appeal. A well-executed fit and finish guarantees that the newly molded parts seamlessly integrate with the existing vehicle body, creating a flawless appearance and ensuring no visible signs of damage remain.

This meticulous process involves careful measurement, precise cutting, and expert application of materials to achieve seamless joints and smooth surfaces. It demands advanced techniques like frame straightening and car scratch repair to restore the vehicle’s original condition. Auto body repair professionals utilize specialized tools and machinery to address any discrepancies, ensuring that every curve, contour, and edge aligns perfectly, enhancing both functionality and visual coherence in the final molding replacement collision restoration.

Why Precision Matters: Impact on Safety, Aesthetics, and Longevity

In the realm of molding replacement collision, precision is paramount. The meticulousness with which parts are manufactured and fitted can significantly impact safety, aesthetics, and longevity. In vehicle collision repair, even minor inaccuracies can lead to structural weaknesses, compromising the protection of occupants during future accidents. Similarly, in car collision repair, off-spec finishes can detract from the vehicle’s overall appearance, undermining its resale value.

Precision molding ensures that replacement parts seamlessly integrate with existing structures, restoring the vehicle’s safety features and aesthetic appeal. This is particularly crucial in today’s market where consumers demand not just functional but also visually appealing vehicles. High-quality fit and finish, achieved through advanced manufacturing techniques, not only enhances the car’s overall look but also reinforces its structural integrity, ensuring long-lasting performance across various vehicle collision repair scenarios.

Best Practices for Achieving Superior Fit and Finish in Automotive Repairs

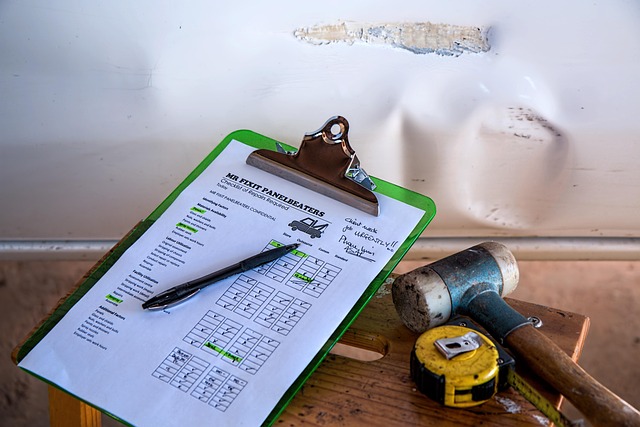

Achieving a superior fit and finish in automotive repairs is paramount for ensuring both aesthetic appeal and structural integrity in molding replacement collision scenarios. Best practices involve meticulous preparation of the car body restoration surface, beginning with thorough cleaning and de-greasing to remove any contaminants that could hinder adhesion. Using high-quality primer and paint designed specifically for automotive applications, along with precise application techniques, is crucial for achieving a seamless finish.

Additionally, skilled technicians employ sandblasting or wet sanding methods to achieve the desired surface smoothness before applying the final coat. This meticulous attention to detail ensures that every curve, contour, and crevice of the car body restoration matches the original manufacturing standards. By combining these techniques with expert auto dent repair skills, the result is a collision-free, factory-like finish that enhances both the functionality and resale value of vehicles undergoing molding replacement collision repairs.

In conclusion, achieving superior fit and finish in molding replacement collision is paramount for ensuring vehicle safety, enhancing aesthetic appeal, and prolonging the lifespan of automotive repairs. By prioritizing precision throughout the process, from material selection to meticulous craftsmanship, professionals can deliver top-notch results that meet the highest industry standards. Incorporating best practices detailed in this article will enable mechanics to consistently achieve impeccable fit and finish, ultimately satisfying even the most discerning car owners.