Electronic measuring equipment revolutionizes auto repair by offering precise assessments and accurate repairs, from simple measurements with digital calipers to complex diagnostics. These tools enhance efficiency, reduce errors, improve vehicle longevity, and are crucial for modern repair shops handling both routine maintenance and extensive damage. Proper selection, training, and regular maintenance ensure their effectiveness in delivering high-quality bodywork services.

In the realm of auto repair, precision is key, and that’s where electronic measuring equipment steps in as an indispensable asset. This complete guide delves into the essential tools that are revolutionizing auto service shops. From understanding the fundamentals of this technology to exploring its diverse types, you’ll discover how these gadgets enhance efficiency and accuracy. Learn the art of selecting and utilizing electronic measuring equipment effectively to master modern auto repair techniques. Uncover the game-changer in workshops: electronic measuring equipment.

- Understanding Electronic Measuring Equipment: Essential Tools for Auto Repair

- Types of Electronic Measuring Equipment Used in Auto Repair

- Selecting and Using Electronic Measuring Equipment Effectively in Auto Service Shops

Understanding Electronic Measuring Equipment: Essential Tools for Auto Repair

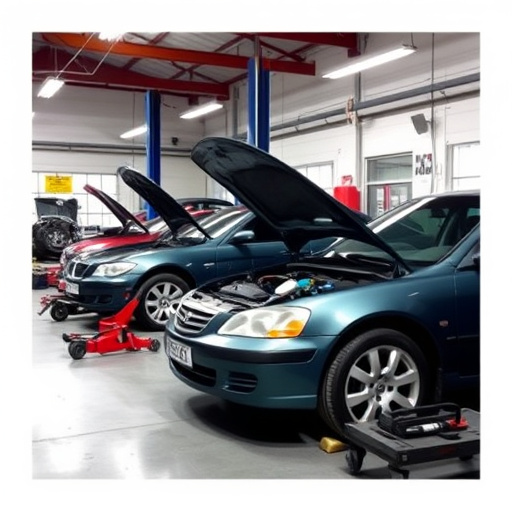

In the realm of auto repair, staying ahead of the curve requires a deep understanding and proficiency with electronic measuring equipment. These tools have revolutionized car bodywork services, enabling precise assessments and accurate repairs that were once more challenging to achieve. By integrating advanced technology, they offer auto detailing professionals an unparalleled level of control and efficiency in their work, from diagnosing complex issues to ensuring meticulous damage repair.

The versatility of electronic measuring equipment is unmatched. They range from simple yet powerful devices like digital calipers for precise measurements, to sophisticated systems capable of conducting intricate diagnostics on various car components. In light of this, these tools have become indispensable assets for any well-equipped auto repair shop. They streamline processes, reduce the risk of errors, and ultimately contribute to higher quality outcomes in both routine maintenance and extensive car damage repair scenarios.

Types of Electronic Measuring Equipment Used in Auto Repair

In the realm of auto repair, electronic measuring equipment plays a pivotal role in ensuring precise and efficient vehicle bodywork. These tools are indispensable for both minor repairs and complex collision repair center operations. Among the various types, laser measurements stand out for their accuracy in assessing panel gaps, ensuring proper alignment during auto body work. This technology enables technicians to detect even the slightest imperfections, facilitating seamless repairs that match factory standards.

Additionally, digital calipers and height gauges are frequently utilized for precise dimensions and angle measurements. These electronic measuring equipment tools are particularly handy in intricate tasks such as frame straightening and suspension adjustments, enhancing overall repair quality. Their advanced capabilities not only speed up the repair process but also contribute to the longevity of vehicles, making them a staple in modern auto body work shops.

Selecting and Using Electronic Measuring Equipment Effectively in Auto Service Shops

Selecting and using electronic measuring equipment effectively is paramount for auto service shops aiming to deliver precision and quality in their work. The first step is understanding your shop’s specific needs. Different tasks require distinct types of equipment, from intricate diagnostics in an auto collision center to precise measurements for auto painting. Investing in versatile, state-of-the-art tools that can handle a variety of tasks is essential for maximizing efficiency.

Once equipped with the right electronic measuring equipment, proper training becomes crucial. Technicians must be adept at calibrating and operating these devices accurately. This ensures reliable results, preventing costly errors and misdiagnoses. Regular maintenance and calibration schedules should be established to keep the tools in optimal condition, mirroring the meticulous attention given to auto bodywork and painting processes.

Electronic measuring equipment has revolutionized auto repair, offering precise diagnostics and efficient service. By understanding different types and selecting the right tools, auto service shops can enhance their capabilities, reduce errors, and provide higher-quality care. This comprehensive guide equips professionals with the knowledge to make informed decisions, ensuring optimal performance and customer satisfaction in today’s advanced automotive landscape.