PDR (Paintless Dent Repair) techniques have revolutionized auto collision repair and restoration, offering a non-invasive method to fix dents and dings without painting. Popular among professionals and enthusiasts, PDR uses specialized tools to gently push dented panels back into place, preserving original paint jobs. Ideal for minor damage, it's cost-effective, efficient, and eco-friendly, with benefits extending to classic car restoration, mobile detailing, and historical artifact preservation. Best practices, including proper preparation, technique, and skilled technicians, ensure exceptional results while staying ahead of industry trends.

“Unleash the power of PDR (Paintless Dent Repair) techniques and discover how they’re transforming the automotive industry and beyond. This innovative approach to dent removal offers a range of advantages, from minimal damage and swift repairs to cost-effectiveness and environmental friendliness.

From car dealerships to bodyshops and even home DIY enthusiasts, PDR techniques are revolutionizing how we handle dents and scratches. Get ready to explore the benefits and best practices for mastering this game-changing method.”

- What Are PDR Techniques and How Do They Work?

- Benefits of Implementing PDR Techniques in Various Industries

- Best Practices for Effective Use of PDR Techniques

What Are PDR Techniques and How Do They Work?

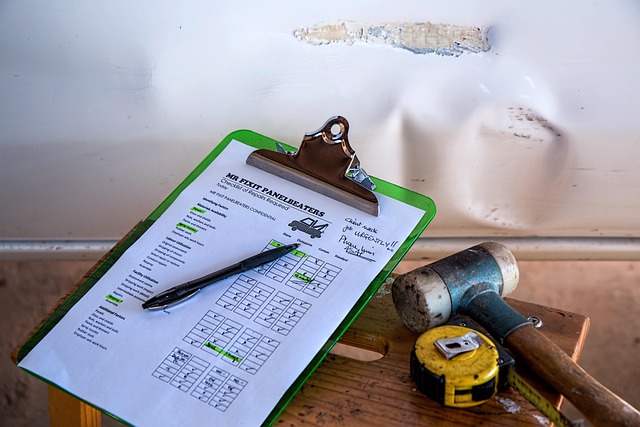

PDR techniques, short for Paintless Dent Repair, are a revolutionary approach to vehicle restoration that has gained immense popularity among car enthusiasts and automotive professionals alike. This innovative method focuses on removing dents and dings from vehicle bodies without the need for sandpaper, chemicals, or extensive painting. By utilizing specialized tools and techniques, PDR experts can effectively reverse damage caused by minor collisions, parking mishaps, or other incidents, resulting in a flawless finish that matches the vehicle’s original paint job.

The process works by accessing the dented area from the exterior of the car, allowing for minimal disruption and preservation of the vehicle’s overall aesthetic. PDR technicians employ a range of tools, including metal rods, air guns, and specialized brushes, to gently push and pull the dented panel back into its original position. This non-invasive approach ensures that the underlying paint and primer remain intact, eliminating the need for extensive repainting or re-coating. Whether it’s removing a door ding, fixing a fender bender, or restoring a vehicle’s overall brilliance, PDR techniques offer an efficient, cost-effective, and environmentally friendly solution for dent removal and vehicle paint repair.

Benefits of Implementing PDR Techniques in Various Industries

Implementing PDR (Paintless Dent Repair) techniques offers significant advantages across various industries. This innovative approach to auto collision repair has transformed the way auto repair shops handle dents and scratches, leading to faster turnaround times and cost savings for customers. By leveraging specialized tools and methods, such as frame straightening without paint removal, PDR allows for precise restoration of vehicles, minimizing the need for extensive repainting.

In the competitive automotive market, this technique is a game-changer for auto repair shops, enabling them to differentiate themselves by offering superior service quality and reduced environmental impact. The benefits extend beyond auto collision repair, as PDR techniques are increasingly adopted in other sectors where aesthetics matter, such as restoration of classic cars, mobile detailing services, and even the preservation of historical artifacts. Its non-invasive nature ensures that surfaces remain intact, preserving original finishes and enhancing longevity.

Best Practices for Effective Use of PDR Techniques

When employing PDR techniques—a cutting-edge approach to vehicle dent repair—adhering to best practices is key to achieving exceptional results. The first step involves thorough preparation, which includes inspecting the damaged area meticulously and identifying any hidden issues that could affect the repair process. Using high-quality tools and materials tailored for PDR ensures precision and longevity in the repair.

Another critical aspect is maintaining proper technique throughout the repair process. Skilled technicians understand the science behind PDR, leveraging tools with specific shapes and applications to gently work out dents without causing further damage or leaving unsightly marks. Regular training on the latest PDR methods keeps collision repair shops at the forefront of this innovative field, offering customers a more efficient, cost-effective, and environmentally friendly alternative to traditional vehicle collision repair.

PDR techniques offer a powerful method to enhance productivity and efficiency across various sectors. By understanding their application and benefits, businesses can unlock new levels of success. These techniques provide a structured approach to problem-solving and decision-making, ensuring that every step is optimized. With the right practices in place, organizations can streamline operations, reduce costs, and improve overall performance. Embracing PDR as a game-changer in today’s competitive market is a strategic move towards achieving long-term growth and staying ahead of the curve.