Remanufactured collision parts offer a sustainable, cost-effective, and safe solution for automotive repairs. By disassembling, inspecting, and repairing damaged components to OEM specifications, these parts reduce environmental impact while providing significant cost savings without compromising safety or reliability. Advanced technologies like paintless dent repair maintain original appearances, adhering to stringent safety regulations set by organizations like SAE and ISO. This revolutionizes auto repairs, streamlining processes, reducing turnaround times, and offering high-quality refurbished parts that rival new components in reliability and durability.

In today’s auto industry, remanufactured collision parts are revolutionizing repair processes. Understanding these parts and their safety aspects is crucial for both consumers and professionals. This article dives into the world of remanufactured collision parts, exploring the process, benefits, and stringent safety regulations they must meet. From enhancing sustainability to providing cost-effective solutions, these parts are reshaping the landscape of automotive repairs, ensuring both quality and safety without breaking the bank.

- Understanding Remanufactured Collision Parts: The Process and Benefits

- Ensuring Safety Compliance: Regulations and Standards for Remanufactured Parts

- The Impact and Advantages of Using Remanufactured Collision Parts in the Auto Industry

Understanding Remanufactured Collision Parts: The Process and Benefits

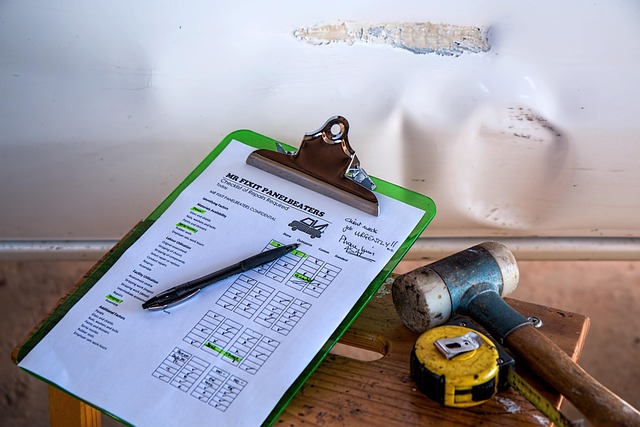

Remanufactured collision parts are a sustainable and cost-effective solution for car body shops and automotive repair centers. The process involves taking damaged or used auto parts, disassembling them, inspecting each component, and then meticulously repairing or replacing necessary elements to meet original equipment manufacturer (OEM) specifications. This meticulous approach ensures that remanufactured collision parts function as good as new, providing excellent performance and safety in vehicle repairs.

One of the key benefits of remanufactured collision parts is their environmental impact. By repurposing existing materials, these parts significantly reduce waste and the need for mining raw resources. Additionally, they offer significant cost savings for both consumers and automotive businesses, making high-quality repairs more accessible without compromising on safety or reliability. Moreover, with advancements in technology, many remanufactured collision parts now include innovative features such as paintless dent repair techniques, ensuring a sleek finish that matches the vehicle’s original appearance, all while adhering to stringent safety regulations.

Ensuring Safety Compliance: Regulations and Standards for Remanufactured Parts

When it comes to remanufactured collision parts, safety is paramount. To ensure consumer protection and vehicle integrity, these parts must meet stringent regulations and industry standards. Organizations like SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization) play a crucial role in establishing guidelines for remanufacturing processes, material quality, and part performance. These standards cover everything from design specifications to testing procedures, guaranteeing that remanufactured collision parts are just as reliable and safe as new ones.

Compliance with safety regulations isn’t merely about meeting legal requirements; it’s also vital for effective vehicle restoration and bumper repair. Remanufactured parts that adhere to these standards contribute to the overall quality of auto detailing services. By prioritizing safety, technicians can restore vehicles to their pre-accident condition, ensuring both aesthetic appeal and structural integrity without compromising on safety.

The Impact and Advantages of Using Remanufactured Collision Parts in the Auto Industry

The use of remanufactured collision parts has significantly transformed the automotive industry, offering a sustainable and cost-effective solution for auto repairs. By utilizing parts that have been carefully refurbished to meet safety regulations, automakers and repair shops can reduce waste, lower environmental impact, and provide high-quality alternatives to new components. This is particularly beneficial in the realm of car body restoration, where remanufactured parts can be just as reliable and durable as their brand-new counterparts.

Moreover, the integration of remanufactured collision parts streamlines auto dent repair processes, contributing to more efficient vehicle turnaround times. This not only benefits repair shops by optimizing their workflows but also offers customers faster and potentially more affordable options for getting their vehicles back on the road. In terms of auto maintenance, these refurbished parts can be a reliable choice, ensuring vehicles meet safety standards while keeping costs down for both consumers and businesses alike.

Remanufactured collision parts have emerged as a game-changer in the auto industry, offering both cost savings and environmental benefits while adhering to stringent safety regulations. By understanding the meticulous process behind their creation and recognizing the impact of these parts on vehicle performance and sustainability, consumers can make informed choices that contribute to a safer and more eco-friendly automotive landscape. The continued growth and acceptance of remanufactured collision parts promise a brighter future for both drivers and the planet.