The four-stage paint system is a meticulous process crucial for automotive body shops, providing optimal results in terms of protection and aesthetics. This system comprises surface preparation, primer application, base coat, and clear coat stages, each demanding specific materials like abrasive papers, paints, and adhesives. Efficient parts availability management, including real-time inventory tracking, strategic supplier partnerships, and regular communication, is vital for smooth operations, high-quality service, and minimizing downtime in Mercedes Benz repair shops or any auto body shop employing this system.

“Unveiling the efficiency of the four-stage paint system, this article delves into its comprehensive overview, exploring how each stage contributes to seamless automotive painting processes. We dissect the critical role of key components, highlighting their unique functionalities in maintaining parts availability.

Through strategic insights, we guide readers on effective management techniques, ensuring uninterrupted operations and minimizing downtime in automotive manufacturing facilities. Unlocking the secrets of this system is a game-changer for optimizing production.”

- Understanding the Four-Stage Paint System: A Comprehensive Overview

- Key Components and Their Functionality in Ensuring Parts Availability

- Strategies for Effective Management of Parts Availability in a Four-Stage Paint System

Understanding the Four-Stage Paint System: A Comprehensive Overview

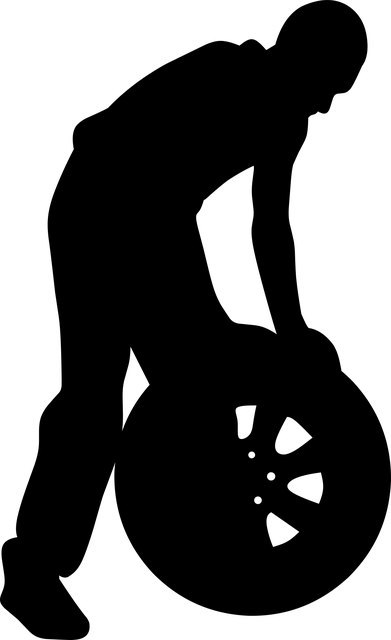

The four-stage paint system is a meticulous process designed to ensure optimal results in automotive body shops and beyond. This system breaks down the painting process into four distinct stages: surface preparation, primer application, base coat, and clear coat. Each stage plays a critical role in achieving a smooth, durable finish that protects the vehicle’s body and enhances its aesthetics.

In an automotive repair or paintless dent repair setting, understanding this system is paramount. Proper surface preparation involves cleaning, priming, and smoothing the damaged area to create a perfect base for subsequent layers. The primer acts as a barrier between the metal and the paint, providing additional protection and ensuring better adhesion. The base coat offers color and coverage, while the clear coat provides the final shine and UV protection, safeguarding against fading and chipping. This systematic approach guarantees not just an attractive finish but also longevity for the vehicle’s painted surface.

Key Components and Their Functionality in Ensuring Parts Availability

The success of a car body shop heavily relies on an efficient parts availability management system. In a four-stage paint system, each stage plays a crucial role in ensuring the seamless provision of necessary components for car paint repair and collision repair services. Firstly, the four-stage paint system comprises preparation, prime coating, base color, and clear coat layers. Each stage demands specific materials, from abrasive papers to various paints and adhesives.

The key components of this system are designed to function cohesively. For instance, the initial preparation stage requires high-quality primers and undercoats to create a clean, rust-free surface, enabling optimal adhesion for subsequent coats. Similarly, the base color and clear coat layers necessitate distinct pigments and resins for accurate color matching and top-notch durability. Efficient inventory management ensures that these components are readily available, minimizing downtime in car paint repair processes and maximizing customer satisfaction in collision repair services.

Strategies for Effective Management of Parts Availability in a Four-Stage Paint System

In a four-stage paint system, efficient parts availability management is key to ensuring smooth operations and maintaining high-quality vehicle repair services, such as those offered in Mercedes Benz repair shops. The first step involves implementing a robust inventory tracking system that provides real-time visibility into stock levels, expiration dates, and location of all paint and related materials. This digital approach allows auto frame repair specialists to anticipate demand, minimize stockouts, and reduce waste.

Moreover, establishing strategic partnerships with reliable suppliers is vital. Negotiating favorable terms, including fast delivery times and dedicated lines for critical parts, can significantly enhance parts availability. Regular communication and collaboration between the auto body shop and suppliers are essential to staying ahead of trends, identifying new product offerings, and ensuring that all necessary components are readily available when handling complex vehicle repair tasks.

The four-stage paint system, with its meticulous process and key components, offers an efficient solution for parts availability management. By understanding each stage and its role, manufacturers can streamline their operations, reduce downtime, and ensure a steady supply of quality components. This strategic approach to parts availability is essential in meeting production demands and maintaining customer satisfaction, ultimately making the four-stage paint system a game-changer in the manufacturing landscape.