Composite material repair is a critical process in the automotive industry, where precision is key to maintaining modern vehicles' strength, performance, and aesthetics. Skilled technicians use advanced techniques and specialized tools for meticulous surface preparation, alignment, and bonding, ensuring structural integrity and long-lasting repairs that seamlessly integrate with composite structures. This precision repair methodology offers cost savings, improved operational efficiency, and extended component lifespans, promoting sustainability in vehicle repair and manufacturing.

In the realm of composite material repair, precision is a game-changer. This article delves into the foundational significance of precise execution for enhancing the durability and performance of composite structures. From understanding the unique challenges of composite materials to exploring how meticulous techniques drive cost-effectiveness and efficiency, each section illuminates why this approach is paramount in today’s advanced manufacturing landscape. Discover how achieving laser-like accuracy in repairs can ensure these structures withstand the tests of time and environment.

- Understanding Composite Material Repair: The Foundation of Precision

- Enhancing Durability and Performance Through Precise Execution

- Cost-Effectiveness and Efficiency: Measuring Success in Composite Repairs

Understanding Composite Material Repair: The Foundation of Precision

Understanding Composite Material Repair: The Foundation of Precision

Composite material repair is a specialized process that demands meticulous attention to detail and precise execution. In today’s automotive landscape, where vehicle bodywork incorporates advanced composite materials for enhanced strength and lightweight properties, the importance of precision cannot be overstated. Composite materials, while offering significant advantages, present unique challenges during repair due to their intricate structures and differing material properties compared to traditional metals.

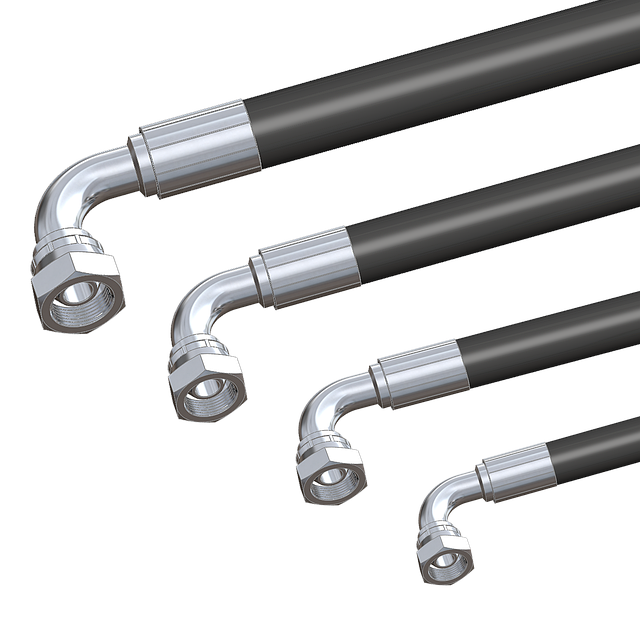

Precision in composite material repair involves several critical steps: careful inspection to identify damage, precise cutting and shaping to replace damaged sections, and meticulous layering and bonding of new composite materials. Skilled technicians utilize specialized tools and techniques to ensure each step is executed flawlessly. This foundation of precision not only guarantees structural integrity but also facilitates the restoration of vehicle aesthetics, aligning with expectations from car repair services and car restoration enthusiasts who prioritize both functionality and visual appeal.

Enhancing Durability and Performance Through Precise Execution

Precision in composite material repair execution plays a pivotal role in enhancing the durability and overall performance of vehicles. Composite materials, known for their strength-to-weight ratio, are increasingly used in modern vehicle manufacturing. However, their intricate structure necessitates meticulous care during repair processes. When repairs are executed with precision, it ensures that the structural integrity of the composite material is preserved, minimizing weakness or points of failure.

This level of precision involves using advanced techniques and specialized tools tailored for composite material repair. It encompasses everything from surface preparation to reinforcement methods. For instance, in a car paint repair or vehicle collision repair scenario, precise alignment and bonding techniques ensure that the repaired area seamlessly integrates with the surrounding composite structure. This results in a robust, long-lasting fix, preventing further damage and enhancing the vehicle’s overall performance, much like restoring a vehicle to its original state through meticulous vehicle restoration processes.

Cost-Effectiveness and Efficiency: Measuring Success in Composite Repairs

Precision in composite material repair execution brings significant advantages in terms of cost-effectiveness and operational efficiency. The success of such repairs is often measured by the minimal deviation from original specifications, ensuring structural integrity and aesthetic appeal. Achieving high precision reduces the need for excessive material replacement, which can be costly in both financial and resource terms. This is particularly beneficial in industries like automotive, where composite materials are increasingly used in vehicle construction, including fender repair and car collision repair processes.

Efficient repairs translate to quicker turnaround times, allowing businesses to service more customers without compromising on quality. Moreover, precise techniques can help extend the lifespan of composite components, thereby deferring the need for frequent replacements. This not only saves money but also reduces waste, contributing to a more sustainable approach in vehicle repair and manufacturing processes.

Precision in composite material repair execution is not just a best practice—it’s a game-changer. By understanding the fundamentals, enhancing durability and performance, and optimizing cost-effectiveness, organizations can significantly improve the outcomes of their composite repairs. This, in turn, extends the lifespan of structures and components, ensuring they meet the highest standards of quality and safety. Embracing precise execution in composite material repair is a strategic move that pays dividends in both the short and long term.