The evolution of wagon design from functional transportation to stylish vehicles has created new challenges in wagon body repair. Early wagons were built for durability with wooden frames, while modern wagons feature intricate paneling and sophisticated safety features requiring specialized tools and expertise. Collision centers have adapted with advanced techniques and technologies for faster, higher-quality repairs, focusing on maintaining structural integrity and aesthetic appeal of wagon bodies. Complex interior layouts and unique design features like extended roofs pose additional challenges, underscoring the specialized nature of wagon body repair within the auto industry.

Wagon body repair has left an indelible mark on the auto industry, transforming not just how vehicles are fixed but also their design and the customer experience. Historically, wagons, with their unique construction, presented specific challenges that drove innovation in repair techniques. This evolution led to groundbreaking advancements, from traditional methods to modern, sophisticated approaches using cutting-edge technology. The far-reaching effects ripple through customization, safety standards, and consumer expectations, solidifying wagon body repair as a revolution within the industry.

- The Evolution of Wagon Design and Its Vulnerabilities

- – A historical perspective on wagon bodies

- – Uncovering the unique challenges of wagon construction

The Evolution of Wagon Design and Its Vulnerabilities

The evolution of wagon design, from its humble beginnings as a simple mode of transportation to the sleek and stylish vehicles we see today, has been a journey marked by both innovation and vulnerability. Initially, wagons were crafted with functionality in mind, featuring sturdy frames and robust bodies designed to withstand rugged terrain and heavy loads. However, as automobiles became more sophisticated, the focus shifted towards aesthetics and performance, leading to lighter materials and more complex designs. This shift presented new challenges for wagon body repair, as these modern vehicles demanded precision and expertise to fix without compromising their structural integrity.

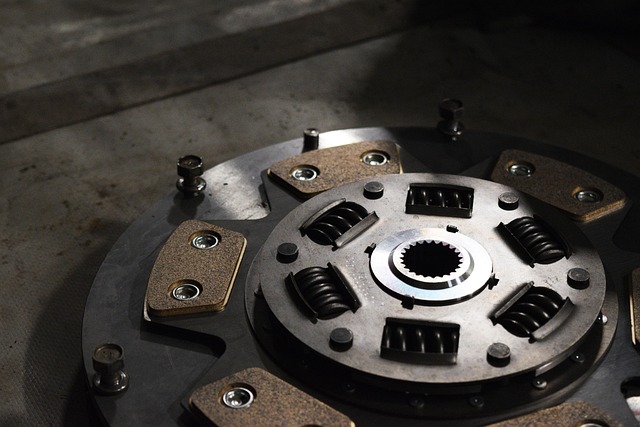

The vulnerabilities of wagon design became increasingly apparent in collision repair shops. Unlike their robust predecessors, contemporary wagons often feature intricate paneling, curved lines, and sophisticated safety features integrated into the bodywork. Damage to these delicate components can result in complex repairs that require specialized tools and a deep understanding of car bodywork services. Moreover, tire services have also become more critical, as the precision alignment and balancing necessary for optimal performance and fuel efficiency are essential to maintaining the overall health of these vehicles.

– A historical perspective on wagon bodies

Wagon bodies have a rich history dating back to the early days of transportation. These sturdy structures were integral to the design and functionality of horse-drawn carriages and, later, the advent of automobiles. Over time, wagon body construction evolved from simple wooden frames to more complex designs incorporating metal components, reflecting advancements in technology and safety standards. The traditional wagon’s enduring influence can be seen in the early models of cars, which often retained the same basic structure, featuring a separate body mounted on a chassis.

The need for efficient and effective wagon body repair became increasingly important as vehicle collision repair gained prominence in the auto industry. As accidents and collisions became more common, specialized facilities known as collision centers emerged to cater to these demands. These centers played a pivotal role in revolutionizing the way wagon bodies and, by extension, vehicles were repaired and restored. Advanced techniques and technologies were introduced, enabling faster turnaround times and higher standards of quality in vehicle collision repair.

– Uncovering the unique challenges of wagon construction

Wagon construction presents a unique set of challenges compared to other vehicle types. Their distinctive design, with an extended roof and often a higher profile, requires specialized skills and tools for effective wagon body repair. The intricate shape and structural integrity of wagons demand precision and expertise to ensure both safety and aesthetics are maintained.

One of the primary difficulties lies in preserving the wagon’s sleek lines and curved surfaces during repairs. Body shops need to employ advanced techniques, such as specialized dent removal methods tailored to these unique panels, to restore the original beauty without compromising structural integrity. Unlike standard cars, wagons may also have complex interior layouts and storage compartments, adding another layer of complexity to repair processes. These factors highlight the specialized nature of wagon body repair and its significant impact on maintaining the overall quality and value of these vehicles within the auto industry.

The evolution of wagon design, coupled with the art of wagon body repair, has left an indelible mark on the auto industry. Once considered a niche segment, wagons have undergone a metamorphosis, navigating through changing consumer preferences and technological advancements. By addressing the unique vulnerabilities of wagon construction, specialists revolutionized their repair process, ensuring these vehicles could withstand the test of time. This shift not only enhanced their durability but also underscored the importance of specialized knowledge in wagon body repair, fostering a vibrant market for restoration and customization.