Mercedes factory seam sealers are crucial for preserving the structural integrity, durability, and aesthetic appeal of luxury vehicles. These specialized adhesives prevent water intrusion and corrosion, ensuring long-lasting performance and safety. In collision repairs, high-quality Mercedes factory seam sealers are vital for restoring vehicles to pre-accident condition, saving time and money while preserving structural strength and safety features. This advanced sealing technology ensures every Mercedes maintains impeccable sealing, preventing water penetration, air leaks, and potential weaknesses, enhancing both the safety and structural durability of the vehicle.

In the heart of automotive manufacturing, the role of a Mercedes factory seam sealer goes beyond aesthetics. This critical component ensures structural integrity and safety by sealing body panels, preventing water intrusion, and minimizing corrosion. Mercedes-Benz’s advanced sealing technology leverages innovative materials to create robust bonds, enhancing durability and reliability. Discover how these seamless solutions contribute to the overall quality and longevity of Mercedes vehicles, prioritizing both passenger safety and performance.

- The Role of Seam Sealers in Automotive Manufacturing

- Mercedes-Benz's Advanced Sealing Technology

- Benefits and Impact on Safety and Durability

The Role of Seam Sealers in Automotive Manufacturing

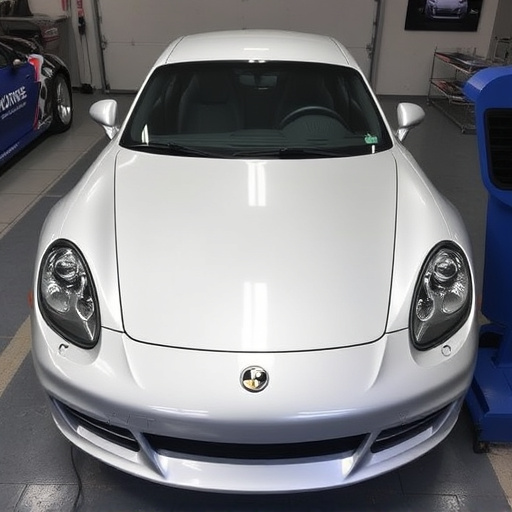

In automotive manufacturing, Mercedes factory seam sealers play a pivotal role in ensuring both safety and structural durability. These specialized adhesives and sealants are crucial for joining various components together, from body panels to interior trims. By effectively sealing seams, they prevent water intrusion, corrosion, and other environmental factors from compromising the integrity of the vehicle’s structure. This is particularly important for luxury brands like Mercedes, where aesthetics and performance go hand in hand.

Moreover, seamless integration achieved through these sealers contributes to overall vehicle quality and longevity. In cases of minor dents or damage, such as those involving fender benders or bumper repairs, proper seam sealer application becomes even more critical. Collision repair services often rely on high-quality Mercedes factory seam sealers to restore vehicles to their pre-accident condition, effectively minimizing the need for extensive body work. This not only saves time and money but also ensures that the vehicle retains its original structural strength and safety features.

Mercedes-Benz's Advanced Sealing Technology

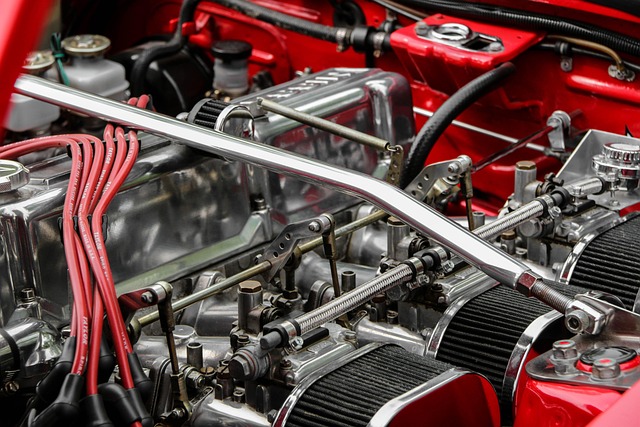

Mercedes-Benz has consistently been at the forefront of automotive innovation, and their advanced sealing technology is a prime example. The Mercedes factory seam sealer is a cutting-edge solution designed to enhance safety and structural integrity. This sophisticated system utilizes high-performance materials to create seamless bonds between various components of the vehicle, from body panels to interior trim.

The integration of this technology in both manufacturing and subsequent vehicle repair services ensures that every Mercedes rolls off the assembly line with impeccable sealing, preventing water intrusion, air leaks, and potential structural weaknesses. This is particularly significant for automotive body shops aiming to restore vehicles to their original condition, as it guarantees a robust and reliable repair, maintaining the car’s safety features and overall performance.

Benefits and Impact on Safety and Durability

The Mercedes factory seam sealer plays a pivotal role in enhancing both safety and structural durability within the automotive industry. This advanced sealing technology is meticulously applied during the manufacturing process, ensuring that every joint and seam on Mercedes vehicles is securely sealed. The benefits are manifold; it prevents water penetration, which can cause corrosion and compromise structural integrity over time. By effectively keeping out moisture and contaminants, the seam sealer contributes significantly to the longevity of the vehicle’s exterior.

Furthermore, this innovative solution fortifies the overall safety of Mercedes cars. Seams, when left unsealed, can become weak points in the body, leading to potential hazards during accidents. The factory-applied sealer creates a robust barrier, minimizing the risk of panel separation and ensuring that the vehicle’s structural integrity remains intact. This is particularly crucial for an automotive body shop aiming to provide top-notch auto maintenance, as it guarantees that any repairs or dent removal processes adhere to the highest safety standards.

Mercedes’ cutting-edge factory seam sealer is a testament to their commitment to both safety and structural durability in automotive manufacturing. By integrating advanced sealing technology, Mercedes ensures that every vehicle not only meets but exceeds industry standards. This investment in innovation directly benefits consumers, guaranteeing the long-term reliability and safety of their vehicles. The use of high-quality seam sealers is a game-changer, fostering a robust and secure car infrastructure.