Frame repair equipment, including specialized machines and precision measuring tools, is vital for professional auto body repairs, particularly for damaged vehicle frames. These tools help technicians accurately assess and correct deformities, ensuring safety and structural integrity. Laser measurements and digital calipers detect subtle misalignments, while frame machines straighten frames to original specifications, crucial for collision repair centers offering high-quality painting services. Puller machines perform paintless dent repair, preserving the factory finish, and frame racks secure vehicles during complex structural repairs. Choosing accurate measuring tools and high-quality equipment is paramount for successful repairs, enabling professionals to restore vehicles to their pre-accident condition efficiently.

“Frame repair equipment is an indispensable asset for professionals in the automotive industry. This essential toolkit includes specialized machines and precise measuring tools designed to address various frame-related repairs. In this comprehensive guide, we delve into the heart of these utilities, exploring frame machines and their diverse functions, as well as the critical role of accurate measuring tools. By understanding these components, mechanics can ensure top-tier frame repairs.”

- Understanding Frame Repair Equipment: Essential Tools for the Job

- Types of Frame Machines: Their Functions and Benefits

- Choosing the Right Measuring Tools for Precise Repairs

Understanding Frame Repair Equipment: Essential Tools for the Job

Frame repair equipment is an indispensable set of tools for any professional involved in auto body repairs, particularly when dealing with damaged vehicle frames. This essential toolkit includes specialized machines and precision measuring instruments designed to accurately assess and correct frame deformities. By employing these tools, skilled technicians can ensure that cars are not only safe to drive but also maintain their structural integrity.

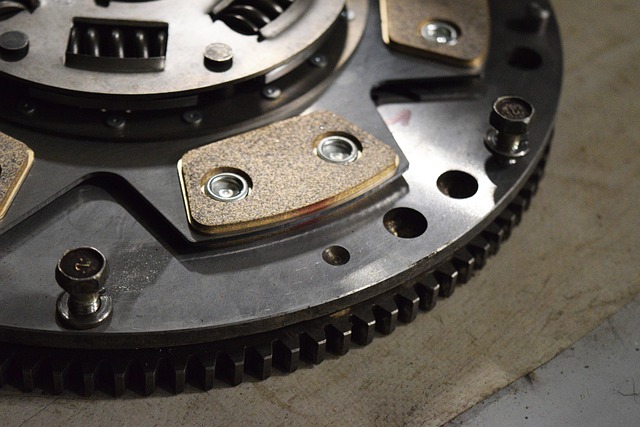

The core of effective frame repair is the ability to precisely identify issues within the car’s body structure. Measuring tools, such as laser measurements and digital calipers, play a pivotal role in detecting even slight misalignments or deformities. Once identified, specialized frame machines step in. These devices are designed to straighten, adjust, and restore damaged frames back to their original specifications. Such equipment is crucial in collision repair centers, enabling them to offer top-quality auto body painting services by ensuring the underlying structure of vehicles is fully restored.

Types of Frame Machines: Their Functions and Benefits

Frame machines are an essential part of any professional frame repair equipment arsenal. These specialized tools come in various types, each designed to serve unique needs within the intricate process of car scratch repair and paintless dent repair. Let’s explore some common types and their functions.

One popular type is the puller machine, used for removing dents without painting. It employs a precise combination of heat and pressure to reshape the damaged area back to its original form. This not only saves time but also preserves the car’s factory finish, making it ideal for those seeking top-notch car repair services. Another variant is the frame rack, which holds the vehicle securely in place during repairs, ensuring stability and precision when dealing with complex structural issues. These machines play a pivotal role in streamlining the entire frame repair process, ultimately enhancing the quality of both paintless dent repair and car scratch repair jobs.

Choosing the Right Measuring Tools for Precise Repairs

When it comes to frame repair, accuracy is paramount. Choosing the right measuring tools is a key step in ensuring successful and precise results. Professionals rely on a variety of tools, including laser measuring devices, calipers, and angle gauges, to accurately assess damage, plan repairs, and ensure proper alignment during frame straightening processes, such as those involved in car collision repair. Investing in high-quality, calibrated measuring tools is an essential part of any comprehensive frame repair equipment arsenal, contributing to efficient auto maintenance and restoring vehicles to their pre-accident condition.

Frame repair equipment, comprising specialized machines and precise measuring tools, is indispensable for maintaining vehicle aesthetics and structural integrity. By understanding the diverse range of frame machines and selecting appropriate measuring instruments, professionals can ensure meticulous repairs, enhancing both the quality and longevity of their work. Investing in these essential tools equips technicians to navigate the intricate landscape of frame repair, ultimately fostering a robust and reliable automotive industry.