Frame repair technology is transforming the automotive industry by automating intricate frame straightening tasks, reducing human error, and ensuring more accurate and consistent auto body restoration. This advanced system uses sensors, CAD, and data analysis to create digital blueprints for damage assessment, leading to higher repair quality and enhanced vehicle safety. By minimizing manual assessments, automated systems offer precise measurements and calculations, streamlining processes from painting to bumper repair while setting new benchmarks for speed, accuracy, and customer satisfaction.

Frame repair technology is transforming structural repairs, minimizing human error and enhancing safety. This advanced approach addresses the current state of repairs plagued by human fallibility. By automating key aspects of the process, frame repair tech ensures precision and consistency, reducing costly mistakes.

This article explores how these innovations work, delves into their benefits, and contemplates the future implications of integrating this cutting-edge technology in construction.

- The Current State of Structural Repair and Human Error

- How Frame Repair Technology Works to Reduce Errors

- Benefits and Future Implications of Implementing Advanced Frame Repair Tech

The Current State of Structural Repair and Human Error

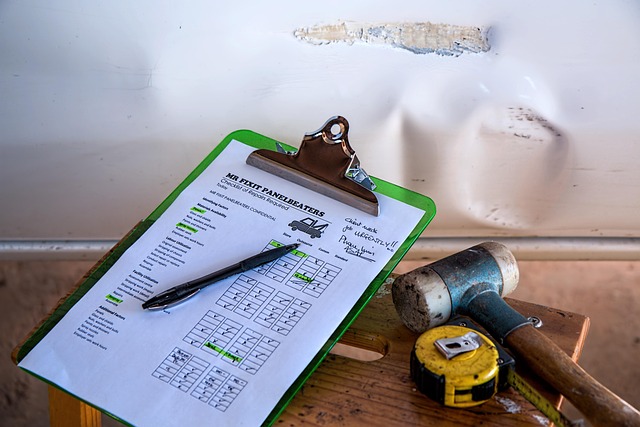

The current state of structural repair, particularly in the automotive industry, heavily relies on skilled labor and manual precision. Traditional methods, while effective, are prone to human error due to factors like fatigue, inexperience, or varying levels of expertise among technicians. This is especially evident in intricate tasks such as frame straightening and alignment during vehicle collision repair and auto body restoration.

Body shop services that involve frame repairs demand meticulous attention to detail. Even slight miscalculations can lead to structural instability or uneven panel fitting. Frame repair technology, therefore, emerges as a game-changer by providing advanced tools and systems designed to streamline these processes. By automating certain aspects of frame straightening and offering real-time feedback, this innovative technology minimizes the impact of human error, ensuring more accurate and consistent results in auto body restoration.

How Frame Repair Technology Works to Reduce Errors

Frame Repair Technology is revolutionizing structural repairs by minimizing human error and maximizing precision. This innovative system utilizes advanced sensors and computer-aided design to analyze and map the damage on a vehicle’s frame, providing an accurate digital blueprint for repair. By automating this process, Frame Repair Technology ensures consistent and repeatable results, reducing the likelihood of mistakes that can occur during manual measurements.

Unlike traditional fender repair or auto dent repair methods, which often involve subjective assessments and hand-based adjustments, Frame Repair Technology leverages data to guide the repair process. This not only streamlines the workflow in car collision repair shops but also enhances the overall structural integrity of the vehicle. By minimizing human error, this technology contributes to safer driving conditions and longer-lasting repairs.

Benefits and Future Implications of Implementing Advanced Frame Repair Tech

The implementation of advanced frame repair technology offers a multitude of benefits for both professionals and clients in the automotive industry. One of its key advantages is the significant reduction in human error, which is often a critical factor in structural repairs. With automated systems, precise measurements and calculations are guaranteed, ensuring that every component of the car’s frame is restored to its original specifications. This precision not only enhances the overall quality of repairs but also increases safety by minimizing the risk of further damage or complications.

Looking ahead, the future implications of this technology are promising. As frame repair technology continues to evolve, it will likely streamline the entire repair process, making car damage repair more efficient and cost-effective. Automated systems can handle complex tasks with minimal supervision, allowing auto body painting and bumper repair processes to be completed faster without compromising quality. This advanced tech promises to revolutionize the way structural repairs are conducted, setting new standards for accuracy, speed, and customer satisfaction in the automotive industry.

Frame repair technology is transforming structural repairs by significantly minimizing human error, a critical factor in ensuring safety and longevity of buildings. By leveraging advanced tools and precision techniques, this innovative approach promises not only enhanced accuracy but also cost-effectiveness and faster turnaround times. As the technology continues to evolve, its implementation will undoubtedly revolutionize the industry, setting new standards for quality and reliability in frame repairs.