Advanced welding techniques like laser welding, robotically-assisted TIG (Tungsten Inert Gas) welding, and MIG (Metal Inert Gas Welding) are transforming automotive repair by offering unparalleled precision, speed, and efficiency. These methods enable skilled professionals to achieve superior work quality, reduce heat input for minimal distortion, and enhance material strength in complex car component repairs and custom fabrication. By leveraging these innovative techniques, modern auto collision repair and restoration processes offer faster turnaround times, improved structural integrity, and more cost-effective solutions.

“Unleash superior craftsmanship with advanced welding techniques—a game-changer for enhancing your outcomes. This comprehensive guide explores the transformative power of these modern processes, from TIG and MIG welding to precision laser fusion. Discover how adopting cutting-edge methods can revolutionize your work, offering unparalleled quality, speed, and strength while reducing waste and costs.

Embrace the future of welding with our expert insights on implementation and optimization, ensuring you harness the full potential of these techniques.”

- Understanding Advanced Welding Techniques

- – Definition and significance of advanced welding techniques

- – Common types of advanced welding processes (e.g., TIG, MIG, laser welding)

Understanding Advanced Welding Techniques

Advanced welding techniques are transforming industries, offering precise and robust solutions for various applications. These techniques go beyond conventional methods, employing innovative approaches to achieve stronger, more aesthetically pleasing welds. By understanding these advancements, professionals in automotive repair and car damage repair can significantly enhance their work quality and efficiency.

In the realm of auto repair shops, advanced welding involves specialized equipment and expert knowledge. Techniques such as laser welding, robotically-assisted welding, and TIG (Tungsten Inert Gas) welding provide unparalleled control and accuracy. These methods ensure minimal heat input, resulting in reduced distortion and improved material strength. Whether it’s repairing intricate car components or fabricating custom auto parts, these advanced techniques offer precise outcomes, making them indispensable for modern automotive repair processes.

– Definition and significance of advanced welding techniques

Advanced welding techniques are specialized procedures that go beyond conventional methods, offering enhanced precision and quality in joining metal components. These innovative approaches play a pivotal role in various industries, notably automotive collision repair and vehicle restoration, where meticulous craftsmanship is paramount. By employing cutting-edge technology and skilled expertise, professionals can achieve intricate welds with superior strength and aesthetics, ensuring the structural integrity of vehicles and enhancing their overall appearance.

In auto maintenance and restoration projects, adopting advanced welding techniques can significantly improve outcomes. These methods allow for complex geometry welds, minimal heat input, and precise control over the fusion process, resulting in reduced distortion, improved joint strength, and enhanced corrosion resistance. This not only accelerates the repair or restoration process but also guarantees long-lasting, reliable connections, contributing to the overall longevity and value of the vehicle.

– Common types of advanced welding processes (e.g., TIG, MIG, laser welding)

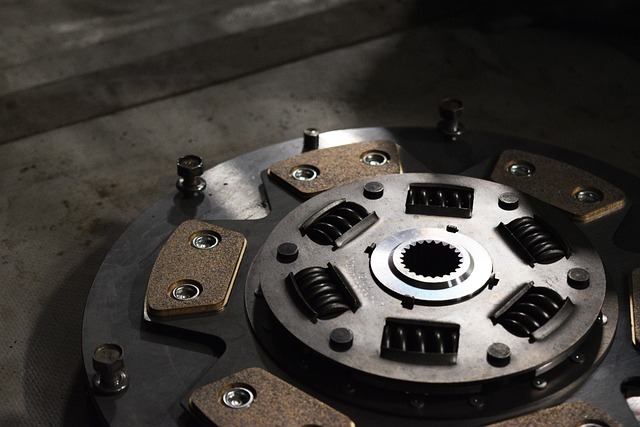

Advanced welding techniques have transformed various industries, including automotive repairs. Processes like TIG (Gas Metal Arc Welding), MIG (Metal Inert Gas Welding), and laser welding offer precision and efficiency unparalleled by traditional methods. TIG welding, for instance, is known for its versatility and ability to weld a wide range of materials, making it ideal for tasks involving auto frame repair and car paint repair. MIG welding, on the other hand, is favored for its speed and ease of use, suitable for everything from quick repairs to intricate joinery.

Laser welding stands out for its extreme precision and minimal heat input, which reduces material distortion and post-weld treatment needs. This advanced technique finds applications in both auto glass repair and car paint repair, ensuring meticulous results with minimal waste. By adopting these cutting-edge processes, professionals can achieve superior weld quality, faster turnaround times, and more cost-effective solutions for various industrial and automotive needs.

Advanced welding techniques offer a world of opportunities for professionals and enthusiasts alike to elevate their craftsmanship. By mastering these processes, such as TIG, MIG, and laser welding, you can achieve unparalleled precision, strength, and versatility in your projects. These techniques aren’t just about achieving stronger bonds; they empower you to create intricate designs and work with diverse materials. Embracing advanced welding practices ensures superior results, fosters innovation, and opens doors to endless creative possibilities in the metalworking realm.