The automotive industry's evolution has shifted from manual, inconsistent measurement methods to a technology-driven revolution led by Tesla's advanced measure system. This digital solution offers precise inspections and repairs beyond basic dimensions, including dent repairs and auto painting touch-ups. Real-time data empowers technicians for excellent vehicle restoration standards, enhancing quality control and streamlining workflows in collision repair centers.

In the ever-evolving landscape of automotive manufacturing, the evolution of measurement systems has been a game-changer. From traditional manual techniques to modern digital innovation, the industry has witnessed a remarkable transformation. At the forefront of this revolution is Tesla’s groundbreaking Measure System, redefining standards with its precision and real-time data analysis. This article explores how Tesla’s approach has not only enhanced production efficiency and product quality but also set new benchmarks, inspiring other manufacturers to embrace digital measurement systems on a larger scale. Discover why Tesla’s measure system is truly setting industry standards now and what the future holds for this transformative technology.

- The Evolution of Measurement Systems

- – A brief history of measurement techniques in the automotive industry.

- – Traditional methods vs. modern digital systems.

The Evolution of Measurement Systems

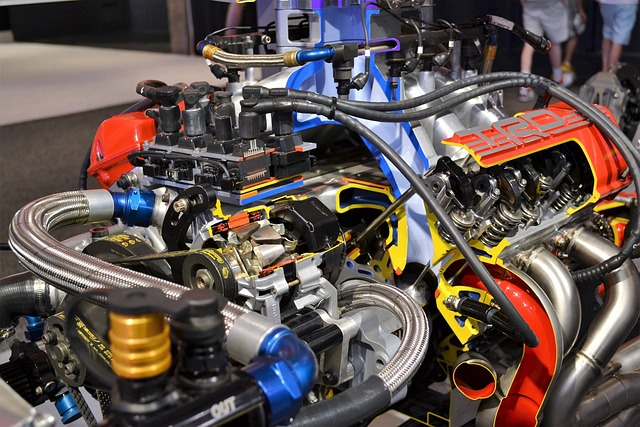

The evolution of measurement systems in the automotive industry has been a transformative journey. In the past, traditional methods relied on manual inspections and crude tools to assess vehicle quality, leading to inconsistencies and time-consuming processes. However, with advancements in technology, the introduction of sophisticated systems like Tesla’s measure system has revolutionized the way cars are inspected and repaired. This digital age has brought about precision and efficiency, ensuring every car undergoes thorough evaluation.

Tesla’s measure system stands out as an industry leader, offering advanced features that go beyond simple dimensions. It facilitates detailed assessments, from identifying subtle car dent repairs to intricate auto painting touch-ups. By providing real-time data, this system empowers technicians to make informed decisions, enhancing overall vehicle restoration and ensuring standards of excellence are met.

– A brief history of measurement techniques in the automotive industry.

The evolution of measurement techniques in the automotive industry has been a gradual yet transformative journey. Historically, the focus was primarily on basic dimensions and physical attributes, with manual measurements taken using tape measures and calipers. As vehicles became more complex, especially with the advent of modern materials and designs, the need for precise and efficient measurement methods became evident. Traditional techniques often fell short in terms of accuracy and adaptability to the ever-changing automotive landscape.

In recent years, Tesla’s measure system has emerged as a game-changer, revolutionizing how the industry approaches measurements. By integrating advanced technologies such as laser scanners and computer-aided design (CAD) software, Tesla has set new standards for accuracy and efficiency in both vehicle manufacturing and collision repair centers. This shift towards digital measurement methods not only streamlines the production process but also ensures consistent quality control, particularly in intricate vehicle components and body restoration tasks within auto body shops.

– Traditional methods vs. modern digital systems.

In today’s digital era, the automotive industry has witnessed a remarkable shift from traditional manual measurement methods to modern, precise digital systems, with Tesla leading the way. The evolution from clunky, time-consuming analog tools to sleek, efficient software applications has revolutionized car restoration and bumper repair processes. Modern digital systems, such as Tesla’s measure system, offer unparalleled accuracy and efficiency in tasks like auto painting, ensuring every detail is accounted for.

This transition isn’t just about convenience; it’s a game-changer that enhances quality control and streamlines workflows. Unlike manual methods, which can be subjective and prone to human error, digital systems provide consistent, data-driven measurements. This ensures that each repair or restoration job is executed with the utmost precision, resulting in superior outcomes for car owners—whether it’s a minor bumper repair or a complete auto painting transformation.

Tesla’s measure system has emerged as a game-changer, revolutionizing the way the automotive industry conducts measurements. By transitioning from traditional analog techniques to modern, digital systems, manufacturers are achieving unprecedented precision and efficiency. The adoption of advanced measurement technologies, such as those employed by Tesla, is setting new industry standards, ensuring higher quality control and facilitating faster innovation in vehicle design and development. This shift marks a significant evolution in automotive engineering, pushing the boundaries of what’s possible on the road.