Spot weld bonding repair is a specialized auto detailing process that restores vehicle structural integrity by joining metal panels with precise spot welds, demanding meticulous surface preparation and clean, contaminant-free metal surfaces. The key steps include thorough inspection, removal of contaminants, degreasing, light etching for texture, rinsing, and drying. Critical mistakes like inadequate cleaning or improper sanding can weaken bond strength and impair the final finish. Achieving a smooth, clean surface through balanced cleaning and precise sanding is essential for both structural integrity and aesthetics in auto body shops and car damage repairs involving spot weld bonding repair.

Ensuring successful spot weld bonding repair starts with proper surface preparation. This comprehensive guide delves into the intricacies of preparing metal surfaces for optimal bond strength. We explore the unique requirements for spot weld repairs, highlighting the importance of cleanliness, surface texture, and material compatibility.

Through a step-by-step process, we detail effective techniques to achieve flawless results. Moreover, we identify common mistakes to avoid, empowering professionals to deliver top-tier welding repair work. Discover the secrets to achieving robust, long-lasting spot weld bonding repairs.

- Understanding Spot Weld Bonding Repair and its Surface Requirements

- The Step-by-Step Guide to Effective Surface Preparation

- Common Mistakes to Avoid During Surface Prep for Optimal Results

Understanding Spot Weld Bonding Repair and its Surface Requirements

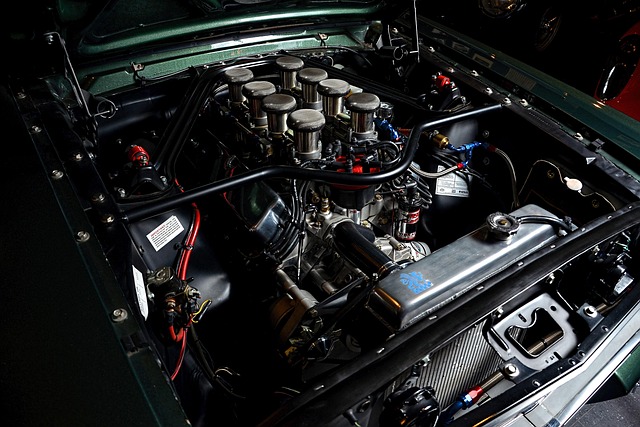

Spot weld bonding repair is a specialized process that involves re-establishing the structural integrity of a vehicle’s body by joining two or more metal panels together using spot welds. This technique is crucial in auto detailing and vehicle body shop operations, as it ensures the durability and aesthetics of vehicle bodywork. The success of this repair heavily relies on proper surface preparation, which includes cleaning, deburring, and ensuring the metal surfaces are free from contaminants, rust, and paint buildup.

Understanding the unique requirements of spot weld bonding repair is essential for achieving long-lasting results. The process demands a seamless fusion between the existing metal and the new weld, requiring a smooth and clean surface to ensure optimal bond strength. Auto detailing professionals must consider factors such as surface texture, moisture content, and overall condition before proceeding with the repair, as these elements can significantly impact the final outcome in terms of both functionality and visual appeal in vehicle body shops.

The Step-by-Step Guide to Effective Surface Preparation

To achieve successful spot weld bonding repairs, a meticulous step-by-step surface preparation process is essential. Begin by thoroughly inspecting the damaged area and surrounding surfaces to identify any contaminants, debris, or existing coatings. Next, using appropriate tools like wire brushes, grinders, or sanders, mechanically remove all loose material, rust, and corrosion from the affected zone. This step ensures clean metal surfaces for optimal bond strength.

After degreasing with a suitable solvent to eliminate oil, grease, and other residues, lightly etch the area using an acid etching solution. This process creates a roughened surface texture that enhances adhesive anchorage. Allow adequate time for etching to take effect before proceeding. Rinse thoroughly with water and ensure the surface is dry prior to applying the spot weld bonding repair materials. Following these precise steps guarantees effective preparation, fostering strong bonds in auto dent repair, car paint repair, and bodywork restoration projects.

Common Mistakes to Avoid During Surface Prep for Optimal Results

When preparing a surface for spot weld bonding repair, many professionals make critical mistakes that hinder optimal results. One common issue is inadequate cleaning. Failure to thoroughly remove grease, dirt, rust, and other contaminants from the affected area can lead to weak bond strength. It’s essential to use appropriate solvents or abrasive materials to ensure the metal surface is clean and free from any debris, especially in the vehicle body shop.

Another frequent error is improper sanding. Aggressive sanding might damage the underlying material, creating an uneven surface that doesn’t promote good adhesion. Conversely, inadequate sanding can leave rough patches, also causing bond failure. For car damage repair or auto body painting projects involving spot weld bonding, the goal is to achieve a smooth, clean finish. This balance ensures both aesthetics and structural integrity in the final product.

Proper surface preparation is key to achieving successful spot weld bonding repairs. By understanding the unique requirements of this process and following a meticulous step-by-step guide, you can avoid common mistakes and ensure optimal results. Remember, paying attention to detail during surface prep will significantly impact the final strength and durability of your welds, making it an indispensable step in any automotive repair or manufacturing process involving spot weld bonding.