Repair Specification Compliance is a critical aspect of vehicle body shop operations, ensuring repairs meet OEM standards for safety, performance, and aesthetics. Non-compliance can lead to subpar quality, legal issues, and voided warranties. Achieving 100% compliance involves well-trained technicians, meticulous documentation, precise adherence to specifications, regular audits, advanced technologies, and peer feedback. This comprehensive strategy guarantees top-quality auto collision repairs, customer satisfaction, and enhanced road safety.

In the realm of factory repairs, adherence to repair specification compliance is paramount. This article delves into the significance of meeting precise standards for manufacturing excellence. Understanding repair specifications ensures consistent product quality and reliability. Explore the profound impact of non-compliance, from increased costs to customer dissatisfaction. Discover strategic approaches to achieve 100% compliance, empowering factories to deliver top-tier repairs and maintain their reputation in today’s competitive market.

- Understanding Repair Specification Compliance

- The Impact of Non-Compliance in Factory Repairs

- Strategies for Ensuring 100% Compliance

Understanding Repair Specification Compliance

Repair Specification Compliance is a critical aspect of vehicle repair processes, especially in reputable auto collision centers and vehicle body shops. It involves adhering to the precise guidelines and specifications outlined in the manufacturer’s repair manual or guidelines for specific vehicle models. These detailed specifications cover everything from the replacement parts used to the step-by-step procedures followed during the repair process.

Ensuring repair specification compliance is vital to guarantee that the final vehicle repair meets the original equipment manufacturer (OEM) standards and maintains the vehicle’s safety, performance, and aesthetic appeal. In a vehicle body shop, technicians must be well-trained in these specifications to accurately diagnose and fix issues without deviating from the prescribed methods. This not only ensures customer satisfaction but also helps protect the integrity of the vehicle, making it an essential practice for any auto collision center aiming to provide top-tier vehicle repair services.

The Impact of Non-Compliance in Factory Repairs

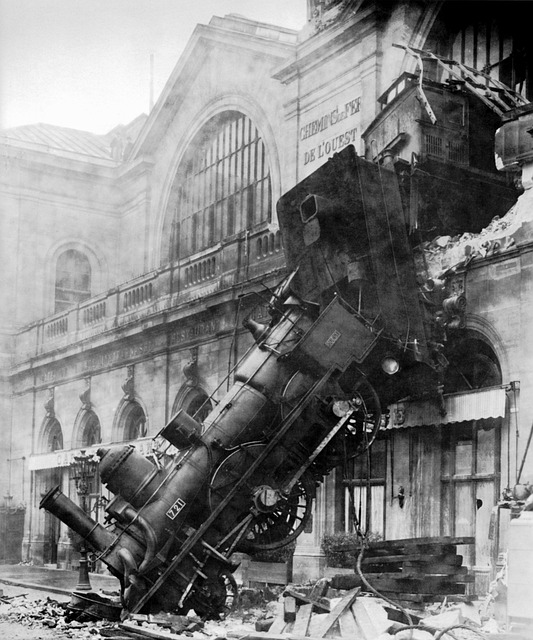

Non-compliance with repair specifications during factory-level repairs can have significant implications for both the vehicle manufacturer and the collision repair center performing the work. When a repair deviates from the specified guidelines, it may result in subpar quality, compromising the safety and performance of the vehicle. This is particularly critical in the automotive industry, where precision and adherence to standards are paramount.

For instance, in a collision repair center, auto dent repair or car bodywork that diverges from the manufacturer’s specifications can lead to issues such as improper alignment, weak structural integrity, or even cosmetic imperfections visible to the naked eye. These discrepancies not only affect the overall customer experience but may also void warranties, creating legal and financial complexities for both parties involved. Therefore, maintaining strict adherence to repair specifications is crucial to ensure the highest quality repairs and prevent potential future problems.

Strategies for Ensuring 100% Compliance

Ensuring 100% repair specification compliance is non-negotiable for achieving top-quality outcomes in auto collision repair or auto bodywork services. A systematic approach, starting with meticulous documentation and clear understanding of the repair specifications, is key. Every detail, from measurement accuracy to material selection, must align perfectly with the specified requirements. Implementing robust training programs for technicians can help ensure they’re well-versed in these specifications, promoting consistency across all repairs.

Regular audits and quality checks at every stage of the repair process are essential strategies. Using advanced technologies like digital measurement tools and automated painting systems can significantly reduce human error and improve precision. Additionally, establishing feedback mechanisms where experienced technicians review and validate each other’s work fosters a culture of continuous improvement. This comprehensive approach guarantees that every vehicle undergoing paint repairs or bodywork restoration meets the highest standards, ensuring customer satisfaction and safety on the road.

Ensuring repair specification compliance is paramount for achieving factory-level repairs that meet quality standards and customer expectations. By understanding the implications of non-compliance and implementing robust strategies, repair facilities can streamline their processes, minimize errors, and deliver consistent, reliable results. Embracing these practices not only enhances operational efficiency but also fosters trust among customers who rely on compliant, high-quality repairs.