Quality Assured Body Work (QABW) is a systematic approach in the automotive industry that ensures vehicle repair compliance with set quality standards, fostering transparency and reliability. Key aspects include meticulous documentation, tracking through digital systems, and collaborative cloud-based storage for real-time updates and repair histories. Best practices involve clear documentation, standardized procedures, staff training, and regular quality control checks by experienced technicians, leveraging technology for enhanced tracking and communication.

Shops across industries are enhancing their operations through Quality Assured Body Work (QABW), ensuring consistent, high-standard outcomes. This article explores the definition and growing importance of QABW in various sectors. We delve into the methods and tools used to track and document these processes, highlighting the significance of consistency and accountability. By implementing best practices, businesses can streamline their workflows, improve product quality, and gain a competitive edge through efficient QABW management.

- Understanding Quality Assured Body Work: Definition and Importance

- Tracking and Documenting Processes: Tools and Techniques

- Best Practices for Maintaining Consistency and Accountability

Understanding Quality Assured Body Work: Definition and Importance

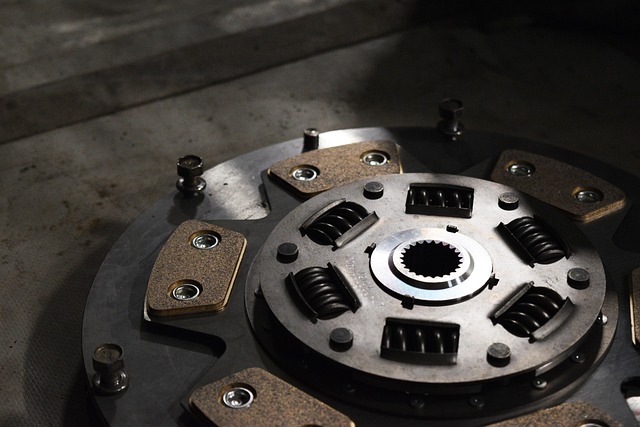

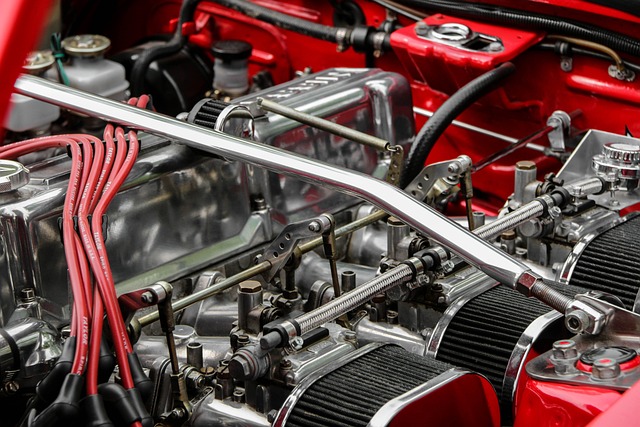

Quality Assured Body Work refers to a systematic approach where shops meticulously document and track every step of their vehicle repair processes, ensuring that all work complies with predetermined quality standards. This concept is vital in the automotive industry as it guarantees customers receive reliable, safe, and high-quality repairs. By implementing strict protocols and detailed documentation, body shops can maintain consistent excellence in their services, from simple vehicle dent repair to complex engine overhauls.

This process is essential for several reasons. It promotes transparency between the shop and the customer, assuring vehicle owners that their cars are in capable hands. Moreover, it enables efficient problem-solving and quality control, as shops can easily identify and rectify any deviations from set procedures, thereby enhancing overall customer satisfaction with body shop services.

Tracking and Documenting Processes: Tools and Techniques

In the realm of quality assured body work, efficient tracking and documentation are paramount to maintaining precision and consistency in auto body repair and car restoration processes. Vehicle body shops utilize a variety of tools and techniques to ensure every step of the auto body painting process is meticulously recorded. Digital systems play a pivotal role here, with specialized software designed to streamline workflow management, from initial assessment to final quality check. These platforms allow for real-time updates, enabling quick access to information about each vehicle’s repair history, specifications, and progress.

Furthermore, cloud-based storage solutions facilitate secure document sharing and collaboration among team members, ensuring everyone works with the most up-to-date records. For instance, detailed work orders that outline specific tasks, parts required, and estimated timelines are digitally documented and easily accessible. This digital approach not only enhances transparency but also serves as a valuable reference for future projects, fostering a culture of continuous improvement within the shop, be it for vehicle body shop repairs or sophisticated car restoration endeavors.

Best Practices for Maintaining Consistency and Accountability

To ensure consistent quality in quality assured body work, shops should implement best practices that promote accountability and uniformity. This starts with clear documentation at every stage of the process, from initial assessment to final inspection. Each step should be meticulously recorded, including the materials used, techniques employed, and outcomes achieved. Standardized procedures and training programs for staff can help maintain consistency, regardless of who is handling a particular vehicle. Regular quality control checks by experienced technicians further ensure that work adheres to set standards.

Additionally, leveraging technology through digital management systems can significantly enhance tracking and accountability. These platforms enable real-time updates, easy access to historical records, and efficient communication among team members. By integrating these best practices into their workflow, collision repair services or auto body restoration shops can guarantee high-quality outcomes while holding themselves accountable for delivering exceptional quality assured body work.

Shops adopting quality assured body work processes benefit from enhanced efficiency, customer satisfaction, and safety. By tracking and documenting each step using advanced tools and adhering to best practices, businesses ensure consistency, accountability, and compliance. This meticulous approach not only elevates the overall quality of services but also fosters trust among clients who value transparency in their automotive care.