In the competitive field of fast collision repair, advanced equipment is crucial for shops to excel. Modern technologies like CAD systems, robotic arms, and specialized machinery streamline repairs, offering quick turnarounds while maintaining or improving quality. Investing in cutting-edge tools like laser measuring, robotic welding, and automated paint systems provides significant advantages, minimizing waste, reducing times, and ensuring superior finishes, ultimately boosting customer satisfaction for top-tier collision repair services.

In today’s competitive automotive industry, consumers demand swift and reliable collision repair services. A shop that excels in fast collision repair isn’t just about speed; it’s a blend of cutting-edge technology, skilled technicians, and streamlined processes. Advanced equipment and trained personnel are the backbone of this efficient service, ensuring precision and timely turnaround. This article explores these key elements, shedding light on what truly makes a shop an expert in fast collision repair.

- Top-Notch Equipment and Technology

- – The role of advanced tools in fast collision repair

- – Benefits of modern equipment for efficiency and precision

Top-Notch Equipment and Technology

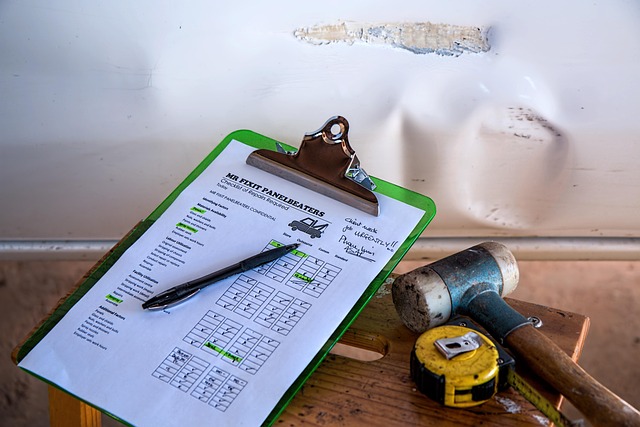

In the realm of fast collision repair, a shop’s efficiency is directly tied to the quality and sophistication of its equipment. Top-notch hardware is the backbone of any proficient auto body repair service. Advanced machines designed for frame straightening, auto dent repair, and car bodywork ensure precise and accurate work, minimizing the time spent on laborious tasks. These technologies not only streamline the collision repair process but also contribute to better outcomes, ensuring that vehicles return to their pre-accident condition or even beyond.

The latest technological advancements play a pivotal role in enhancing precision and speed. From computer-aided design (CAD) systems for accurate measurements to robotic arms facilitating complex body panel replacements, these innovations are game changers. Such tools not only improve the overall efficiency of fast collision repair but also empower technicians, enabling them to tackle even the most intricate car bodywork tasks with ease and confidence.

– The role of advanced tools in fast collision repair

In today’s fast-paced world, where convenience and speed are paramount, advanced tools play a pivotal role in making a shop stand out as an expert in fast collision repair. These cutting-edge technologies have revolutionized the way body shop services are delivered, enabling collision repair centers to offer quick turnarounds without compromising on quality. From robotic welding systems that ensure precise and efficient repairs to computer-aided design (CAD) software that facilitates accurate measurements and calculations, these tools streamline every step of the process.

Additionally, advanced machinery for vehicle dent repair, such as pneumatic hammers and vacuum bagging systems, facilitates quick and effective removal of dents, further accelerating the overall restoration process. This combination of state-of-the-art technology and skilled technicians ensures that customers receive top-notch body shop services in a fraction of the time it would take using traditional methods. As a result, collision repair centers that invest in these advanced tools not only meet but exceed expectations for fast collision repair.

– Benefits of modern equipment for efficiency and precision

In the fast-paced world of collision repairs, staying ahead means embracing modern technology. Shops that invest in cutting-edge equipment reap significant benefits when it comes to efficiency and precision. Advanced tools such as laser measuring systems enable technicians to capture exact dimensions of damaged areas, ensuring accurate repairs and minimal material waste. This translates to faster turnaround times and cost savings for both the shop and its customers, a key factor in maintaining competitiveness in the fast collision repair market.

Moreover, modern equipment facilitates intricate auto body restoration tasks with unprecedented precision. For instance, robotic welding systems enhance consistency and speed while minimizing heat impact, preserving the integrity of surrounding panels. Similarly, automated paint spraying systems offer even coating distribution, reducing the risk of human error and resulting in a more durable, factory-like finish. These innovations not only elevate the overall quality of auto body restoration but also contribute to customer satisfaction, driving demand for top-tier collision repair services.

A shop that excels in fast collision repair leverages top-notch equipment and technology, ensuring precision and efficiency throughout the process. Advanced tools streamline operations, minimizing downtime and maximizing customer satisfaction. By investing in modern equipment, these experts can deliver high-quality repairs quickly, setting them apart in a competitive market and fostering trust among their clientele for all future collision-related needs.