The modern B-pillar, a critical structural element in vehicles, has evolved from a vertical support to an integrated design feature while preserving its safety function. Due to varying vehicle models and complex systems like side impact airbags, replacing a B-pillar is not a universal process. Professional services are recommended for proper alignment, safety standards, and vehicle integrity, including tire and fender repairs if needed. Advanced materials, fabrication techniques, and auto body painting methods are now explored to replace traditional B-pillars, ensuring enhanced safety, lightweight design, and aesthetic innovation in modern vehicles.

In modern vehicle designs, the B-pillar—a critical structural element supporting roof integrity and passenger safety—is facing unprecedented challenges. As cars evolve with lighter materials, enhanced aerodynamics, and advanced driver assistance systems, replacing the B-pillar becomes a complex task. This article delves into the understanding of B-pillar structure and its evolving role in vehicle design. We explore key challenges, from technical constraints to safety considerations, while highlighting innovative alternatives that could reshape future mobility.

- Understanding B-Pillar Structure and Function in Modern Vehicles

- Key Challenges in Replacing B- Pillars: Technical and Safety Considerations

- Exploring Alternatives: Innovative Solutions for Enhanced Vehicle Design and Safety

Understanding B-Pillar Structure and Function in Modern Vehicles

The B-pillar, a structural element found in modern vehicles, plays a crucial role in supporting the roof and providing lateral protection to occupants. In recent years, as vehicle designs have evolved, the B-pillar has transformed from a traditional vertical support to a more integrated and aesthetically pleasing component. Its primary function remains unchanged—to ensure passenger safety during collisions—but its form has become an essential part of the vehicle’s overall design language. This evolution presents unique challenges when it comes to B-pillar replacement, especially as vehicles incorporate advanced safety features and dynamic styling.

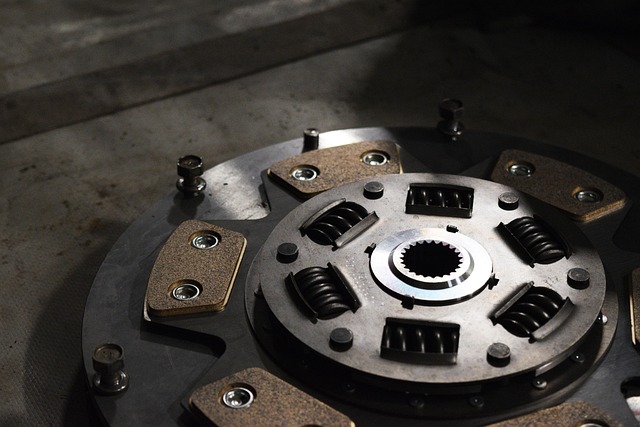

B-pillar replacement is not a one-size-fits-all process. With varying designs across different vehicle models, the removal and installation of a new pillar require specialized knowledge and tools. Moreover, modern cars often feature complex systems integrated into the B-pillar, such as side impact airbags and advanced sensors, which must be carefully handled during the repair or replacement process. Vehicle owners should seek professional services for such tasks, ensuring proper alignment and safety standards are met, including tire services and fender repairs if necessary, to maintain the vehicle’s structural integrity and performance.

Key Challenges in Replacing B- Pillars: Technical and Safety Considerations

Replacing B-pillars in modern vehicle designs presents a unique set of challenges that go beyond mere structural integrity. The key consideration is balancing technical feasibility with safety standards, especially as vehicles evolve to incorporate advanced materials and design aesthetics. In today’s automotive landscape, where lightweight materials like aluminum and carbon fiber are increasingly popular, replacing the B-pillar requires sophisticated engineering to maintain structural rigidity while adhering to stringent safety regulations.

Technical challenges include ensuring proper load distribution in vehicle collision repair, which is crucial for passenger safety. Body shop services must employ innovative techniques such as advanced welding methods or specialized adhesives to replace the B-pillar without compromising structural integrity. Moreover, the seamless integration of new materials and designs requires meticulous precision during replacement, often necessitating advanced car paint services to match the existing body panel finishes flawlessly.

Exploring Alternatives: Innovative Solutions for Enhanced Vehicle Design and Safety

In modern vehicle design, exploring alternatives to traditional B-pillar replacement is a testament to the industry’s constant pursuit of enhanced safety and aesthetic innovation. Engineers and designers are diving into uncharted territories to create structures that not only meet stringent safety regulations but also contribute to improved car performance and reduced weight. One such solution involves rethinking structural elements through advanced materials and fabrication techniques, offering lightweight alternatives without compromising integrity.

This shift towards innovative B-pillar replacement strategies extends beyond mere functionality; it encompasses the overall vehicle restoration process. As cars evolve, the need for seamless integration of safety features and sleek designs becomes increasingly crucial. Auto body painting and restoration techniques play a pivotal role in achieving this balance. By combining cutting-edge materials with meticulous craftsmanship, auto body restoration specialists ensure that vehicles not only meet modern safety standards but also retain their aesthetic appeal, creating a harmonious blend of performance, security, and visual allure.

Modern vehicle designs present unique challenges when it comes to B-pillar replacement, as these structural elements are crucial for both safety and aesthetic integrity. By addressing technical and safety considerations, automakers can explore innovative alternatives that enhance overall vehicle design while maintaining stringent safety standards. Continued advancements in materials science and engineering will be pivotal in overcoming these challenges, paving the way for more streamlined and efficient vehicle architectures. Effective B-pillar replacement strategies not only improve vehicle performance but also contribute to the development of safer, more sustainable transportation solutions.