Technician safety equipment is crucial for the automotive industry, ensuring compliance with regulations and prioritizing worker well-being. It includes protective gear, protocols for hazardous materials, and equipment for operating heavy machinery, mitigating risks from tasks like dent removal and body repairs. Specialized gear protects against physical injuries and exposure to harmful substances, with proper usage including respirators, safety goggles, and insulated gloves. Regular training on personal protective equipment (PPE) and maintaining equipment is vital for fostering a culture of safety, benefiting both technicians and employers by preventing accidents, injuries, and fines.

Technician safety equipment plays a vital role in ensuring compliance with safety regulations, safeguarding professionals from potential hazards in their line of work. This article delves into the critical components of understanding safety standards specific to technicians and how the right gear can mitigate risks. We explore the significance of proper use and maintenance practices, emphasizing their impact on fostering a safe environment for technicians while adhering to legal requirements.

By equipping yourself with the knowledge of these guidelines, you’ll be empowered to make informed decisions regarding technician safety equipment.

- Understanding Safety Regulations for Technicians

- The Role of Technician Safety Equipment

- Ensuring Compliance Through Proper Use and Maintenance

Understanding Safety Regulations for Technicians

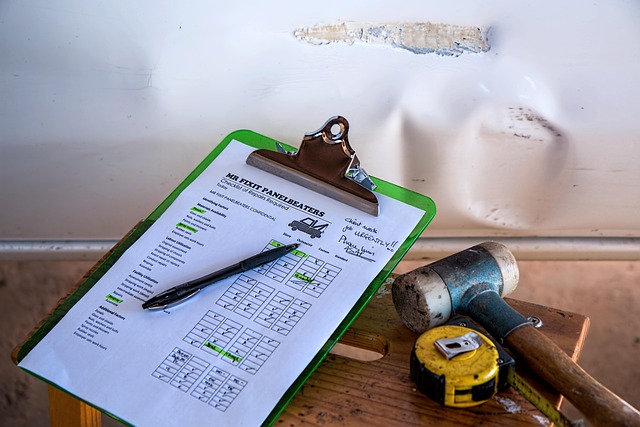

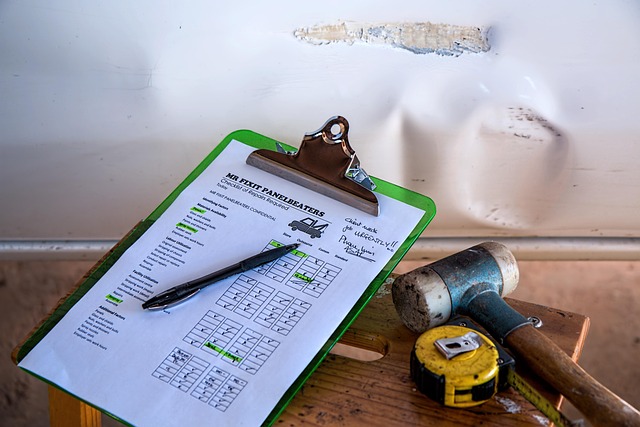

Technician safety equipment plays a pivotal role in ensuring that automotive professionals adhere to stringent safety regulations across various industries. These regulations are designed to protect technicians working on vehicles, ranging from simple dent removal to complex vehicle body repair. Understanding and adhering to these standards is not just a legal requirement but also crucial for the well-being of the workforce.

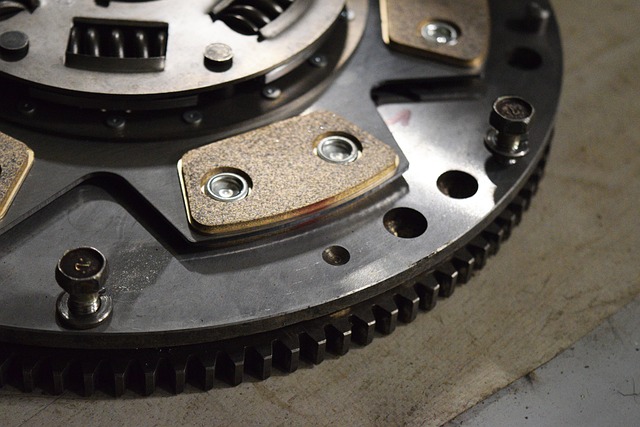

Safety regulations cover a broad spectrum of issues, including proper use of protective gear like gloves, goggles, and respirators; safe handling of hazardous materials commonly found in vehicles; and adherence to protocols during tasks such as welding, painting, and working with heavy machinery. Technician safety equipment is specifically designed to mitigate risks associated with these activities, ensuring that the work environment is as safe as possible for all involved.

The Role of Technician Safety Equipment

Technician safety equipment plays a pivotal role in ensuring compliance with safety regulations across various industries, particularly in fields like automotive repairs. When it comes to tasks such as fender repair or car scratch repair, auto body repair technicians are often faced with potential hazards that require specialized protective gear. This equipment is designed not just to safeguard against physical injuries but also to mitigate risks associated with exposure to harmful substances commonly found in auto shops, including solvents and metals.

Proper use of technician safety equipment includes respirators for protecting against toxic fumes during painting or sanding processes, safety goggles to shield eyes from debris, and insulated gloves for handling electrical components or working with hot materials. By adhering to these standards, technicians not only protect themselves but also contribute to maintaining a safe work environment, thereby facilitating compliance with industry regulations. This, in turn, enhances the overall quality of services provided in fender repair, car scratch repair, and auto body repair sectors.

Ensuring Compliance Through Proper Use and Maintenance

Technician safety equipment plays a vital role in ensuring compliance with safety regulations within auto body restoration and automotive collision repair settings. Proper use and regular maintenance of this equipment are essential to safeguard workers from potential risks and hazards inherent in these industries. By adhering to strict guidelines for technician safety, businesses can mitigate the chances of accidents, injuries, and costly fines associated with non-compliance.

Regular training sessions on the correct usage of personal protective equipment (PPE), such as gloves, eye protection, and respirators, are necessary. Technicians must understand when and how to don these tools effectively. Additionally, maintaining equipment in good working order is crucial. Regular checks, repairs, and replacements ensure that safety devices like fire extinguishers, emergency showerheads, and first-aid kits function optimally during accidents or emergencies. This proactive approach to compliance fosters a culture of safety within the workplace, ultimately benefiting both technicians and employers.

Technician safety equipment is not just a tool, but a vital component in ensuring compliance with safety regulations. By understanding the specific requirements for technicians and providing appropriate gear, organizations can create a culture of safety. Proper use and regular maintenance of this equipment are key to mitigating risks and upholding standards. Investing in high-quality technician safety equipment and training can significantly reduce accidents and fines, making it an essential strategy for any industry looking to stay compliant.