Hydraulic frame machines are essential tools for automotive structural repairs, offering precision in straightening vehicle frames and ensuring post-accident structural integrity. Skilled technicians emphasize accurate calibration and meticulous maintenance to prevent weaknesses and handle complex repairs effectively. Proper documentation, adherence to manufacturer standards, and best practices after repair are crucial to maintain vehicle quality, avoid voided warranties, and promote longevity.

In today’s industrial landscape, understanding and maintaining hydraulic frame machines is paramount. These versatile structures underpin countless operations, making their reliable operation crucial. When repairs are necessary, navigating structural warranty considerations becomes essential to prevent costly pitfalls. This article guides you through the intricacies of these considerations, from comprehending the significance of hydraulic frame machines to adopting best practices for prolonged longevity after repairs.

- Understanding Hydraulic Frame Machines and Their Significance

- Key Structural Warranty Considerations for Repairs

- Best Practices for Ensuring Longevity After Frame Machine Repairs

Understanding Hydraulic Frame Machines and Their Significance

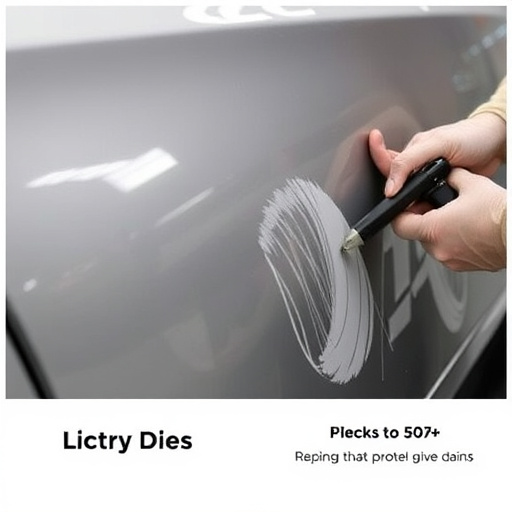

Hydraulic frame machines are essential tools in the automotive industry, particularly for structural repairs. These advanced pieces of equipment utilize hydraulic power to straighten and reshape vehicle frames after accidents or damage. In a car collision repair or bumper repair scenario, ensuring the frame is aligned precisely is crucial for safety and vehicle performance. A skilled technician understands that effective use of a hydraulic frame machine involves meticulous calibration to avoid misalignment, which could lead to structural weaknesses and handling issues.

For car body shops dealing with complex repairs, investing in high-quality hydraulic frame machines offers numerous advantages. They streamline the straightening process, reducing labor hours and increasing efficiency. Moreover, these machines enable technicians to restore vehicles to their original structural integrity, preparing them for a smooth return to the road after an accident, whether it’s a minor fender bender or a severe collision.

Key Structural Warranty Considerations for Repairs

When undertaking repairs with a hydraulic frame machine, several key structural warranty considerations come into play. First and foremost, ensure that the machine is accurately calibrated and maintained to precise standards. Any discrepancies in alignment or adjustments could compromise the structural integrity of the vehicle post-repair, potentially voiding any existing warranties on the car body shop’s work.

Additionally, careful documentation and record-keeping are vital. This includes detailed notes on the initial damage, the repair process, and final inspections. For complex vehicle paint repairs or vehicle body repairs that involve intricate structural components, it’s crucial to have a clear audit trail that demonstrates compliance with manufacturer guidelines and industry best practices. This not only safeguards against future warranty claims but also ensures customer satisfaction.

Best Practices for Ensuring Longevity After Frame Machine Repairs

After repairs using a hydraulic frame machine, adhering to best practices is essential to ensure the longevity and structural integrity of the vehicle. The first step involves thorough inspection post-repair to identify any remaining issues or misalignments. Advanced techniques like digital measurements and computer-aided analysis can detect even subtle abnormalities that might impact the vehicle’s performance and safety.

Regular maintenance checks are crucial, including periodic frame inspections, lubrication of moving parts, and adherence to recommended service intervals. Utilizing specialized car repair services with experienced technicians ensures these tasks are executed accurately. Additionally, for optimal results in vehicle bodywork restoration and frame straightening, it is vital to follow the manufacturer’s guidelines and use high-quality replacement parts.

In conclusion, understanding the intricacies of hydraulic frame machines and prioritizing structural warranty considerations during repairs are essential steps towards ensuring their longevity. By adhering to best practices, technicians can foster robust and lasting solutions, maximizing the performance and lifespan of these critical pieces of equipment. Awareness of potential issues and proper maintenance routines are key to navigating the complexities of frame machine repairs, ultimately benefiting the reliability and efficiency of operations that rely on these machines.