Tesla employs a rigorous, data-driven Tesla totaled vehicle assessment process using advanced sensors and tools. Certified technicians inspect for damage and test safety systems, determining reparability. This method includes frame straightening, sensor functionality checks, and data analysis from vehicle logs. A step-by-step guide outlines the procedure, ensuring safe disassembly, testing, and decision-making based on evidence and cost. Proper documentation facilitates efficient handling of totaled vehicles for recycling or repair, upholding Tesla's safety standards.

“In the realm of electric vehicles, Tesla’s totaled vehicle assessment process stands out. This comprehensive evaluation ensures that damaged cars are either repaired or recycled responsibly. With a sophisticated sensor network playing a pivotal role, the assessment accurately identifies and classifies damage.

Our article delves into the intricate details, offering a step-by-step guide to understanding and evaluating Tesla’s totaled vehicles through their sensor network technology. Discover how this system contributes to sustainable practices in the automotive industry.”

- Understanding Tesla's Totaled Vehicle Assessment Process

- The Role of Sensor Networks in Evaluating Damage

- Step-by-Step Guide to Senor Network Evaluation for Totaled Teslas

Understanding Tesla's Totaled Vehicle Assessment Process

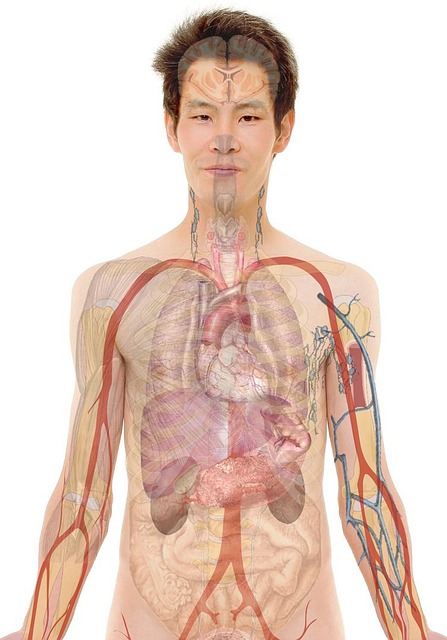

Tesla’s Totaled Vehicle Assessment process is a meticulously designed system to evaluate and determine the condition of its electric vehicles after an accident. When a Tesla encounters an auto collision, the first step involves a comprehensive inspection by certified technicians who employ advanced diagnostic tools to assess any damage. This initial assessment goes beyond merely checking for visible car bodywork scars; it delves into the vehicle’s sensor network, ensuring that all critical safety systems function optimally post-collision.

The process includes meticulous frame straightening techniques to realign any bent metal, followed by rigorous tests to verify the performance of sensors crucial for autonomous driving and collision avoidance systems. This thorough evaluation ensures that Tesla can accurately gauge whether a totaled vehicle is suitable for repair or if it needs to be recycled, promoting safety standards and responsible auto collision repair practices.

The Role of Sensor Networks in Evaluating Damage

Sensor networks play a pivotal role in modern vehicle assessment, especially when it comes to Tesla totaled vehicle evaluations. These advanced systems are designed to capture intricate data during and after a car collision, offering invaluable insights into the extent of damage. By deploying a network of sensors around the vehicle, engineers can measure displacement, deformations, and stress concentrations, providing a comprehensive picture of structural integrity.

This data-driven approach is crucial for accurate frame straightening and automotive repair procedures. It enables technicians to make informed decisions, ensuring that every component is safely replaced or repaired, thereby enhancing safety and performance standards. With sensor networks, the process of Tesla totaled vehicle assessment becomes more precise, efficient, and aligned with modern repair techniques, ultimately optimizing the car collision repair experience.

Step-by-Step Guide to Senor Network Evaluation for Totaled Teslas

When assessing a totaled Tesla for potential salvage or recycling, a thorough sensor network evaluation is crucial. This step-by-step guide will help navigate the process, ensuring accurate valuation and efficient handling of damaged vehicles.

1. Safety First: Begin by ensuring the vehicle is stable and secure. Totaled cars often have compromised structural integrity, so wear protective gear and use jack stands if necessary.

2. Visual Inspection: Documenting initial damage is key. Examine each sensor meticulously – from camera and radar units to ultrasonic sensors – for visible signs of harm. Note any cracks, missing components or discrepancies in the network’s performance during this phase.

3. Functional Testing: Use specialized diagnostic tools to check sensor functionality. Verify that cameras provide clear images, radars detect objects accurately, and ultrasonic sensors are consistent in measuring distances. Any malfunction indicates repairable issues or potential component replacements.

4. Data Analysis: Retrieve and analyze vehicle data logs stored within the Infotainment system or ECU (Electronic Control Unit). These records can reveal pre-impact conditions and post-crash sensor behavior, aiding in understanding the extent of damage and potential electronic failures.

5. Component Disassembly and Inspection: For sensors that require physical disassembly, carefully take them apart for close inspection. Check for water damage, corrosion, or internal debris that could affect performance.

6. Replacement vs. Repair: Based on visual, functional, and data evidence, decide on repairability. Some sensors may be cost-effectively repaired, while others might need complete replacement. This step involves comparing the value of repairs with the cost of new components, considering market prices and availability.

7. Documentation and Reporting: Maintain detailed records of each sensor’s condition and your findings. Prepare a comprehensive report for stakeholders, including photos, data logs, and recommendations for further actions like disassembly or replacement.

Tesla’s sensor network plays a pivotal role in their totaled vehicle assessment process, providing an efficient and comprehensive way to evaluate damage. By utilizing this technology, Tesla can accurately determine the feasibility of repair, ensuring that only eligible vehicles are returned to the road. This method not only enhances safety but also promotes sustainability by minimizing resource-intensive repairs. Understanding these assessment processes is key for both consumers and experts navigating the EV market, highlighting the importance of advanced sensor networks in shaping the future of automotive damage evaluation.