Digital scanners are revolutionizing bumper paint matching in auto repair, providing accurate color analysis and matching against manufacturer specifications. By capturing detailed measurements and data, these tools ensure seamless integration of repaired bumpers with a vehicle's original finish, enhancing aesthetics, resale value, and structural integrity. To maximize benefits, workshops should invest in high-quality scanners, properly train staff, and integrate scanner data into existing paint systems.

Digital scanners are transforming the automotive industry by significantly improving accuracy in bumper paint matching. This article delves into the intricacies of bumper paint matching and its challenges, exploring how digital scanners leverage advanced technology to achieve precise color matches. We discuss the benefits of adoption, including enhanced efficiency, reduced waste, and improved customer satisfaction, providing implementation strategies for auto body shops aiming to integrate this game-changing technology.

- Understanding Bumper Paint Matching and Its Challenges

- The Role of Digital Scanners in Enhancing Accuracy

- Benefits and Implementation Strategies for Digital Scanner Adoption

Understanding Bumper Paint Matching and Its Challenges

Bumper paint matching is a critical process in vehicle body repair, especially when it comes to collision repair and car body repair. It involves accurately recreating the original factory finish on a vehicle’s bumper after damage or wear has occurred. The challenge lies in achieving an exact color match, ensuring the new paint seamlessly blends with the existing panels and overall vehicle aesthetics. Traditional methods often relied on human expertise, which could be time-consuming and inconsistent due to factors like lighting conditions and subjective perception of color.

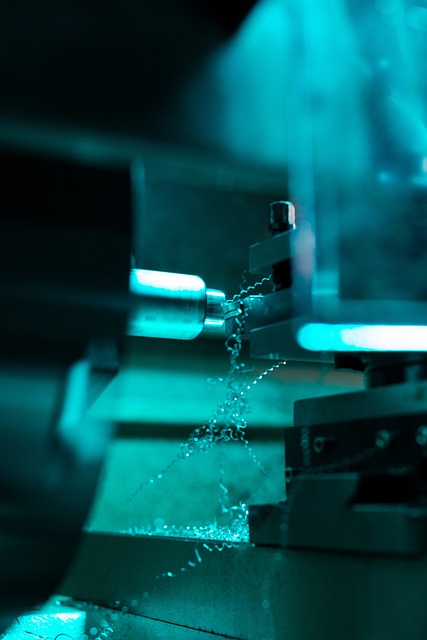

In the realm of collision repair, where precision is paramount, digital scanners have emerged as game changers. These advanced tools use sophisticated technology to capture detailed measurements and color data from the vehicle’s surface, providing a comprehensive digital blueprint. By comparing this data with available paint codes and specifications, technicians can now achieve unparalleled accuracy in bumper paint matching. This not only enhances the visual appeal of the repaired vehicle but also ensures structural integrity, as precise painting hides potential imperfections that might compromise safety.

The Role of Digital Scanners in Enhancing Accuracy

Digital scanners have revolutionized the way auto repair shops approach bumper paint matching, significantly enhancing accuracy and efficiency in vehicle paint repair processes. These advanced tools capture detailed images and data from damaged bumpers, allowing for precise color analysis and matching. By comparing scanned data with original manufacturer specifications, technicians can ensure seamless integration during vehicle dent repair, resulting in a flawless finish that matches the rest of the car perfectly.

In the realm of auto repair shops, digital scanners play a pivotal role in streamlining bumper paint matching tasks, which are crucial for maintaining the aesthetic appeal and resale value of vehicles undergoing vehicle dent repair. This technology not only saves time but also minimizes the risk of human error, ensuring that every repaired vehicle sports a color-coordinated bumper that seamlessly blends with its overall design—a key aspect in satisfying customers who seek top-notch vehicle paint repair services.

Benefits and Implementation Strategies for Digital Scanner Adoption

The adoption of digital scanners is transforming the automotive industry, particularly in the realm of bumper paint matching. These innovative tools offer several key benefits over traditional methods. Firstly, they provide precise measurements and data capture, ensuring consistent and accurate color matching across various car bodywork surfaces. This precision is crucial for achieving seamless auto body painting results, especially when dealing with intricate designs and hard-to-match shades.

Implementing digital scanners requires a strategic approach. Workshops should invest in high-quality scanners capable of capturing detailed images and spectral data. Training staff to operate these devices effectively is essential. Additionally, integrating scanner data into existing paint mixing and matching systems can streamline the process further. By adopting these strategies, tire services can enhance their capabilities, reduce paint wastage, and deliver superior bumper paint matching results, ultimately satisfying customers with precise and long-lasting finishes.

Digital scanners have emerged as powerful tools, revolutionizing the way we approach bumper paint matching. By accurately capturing and analyzing color data, these scanners ensure precise matches, minimizing errors often associated with traditional methods. The benefits are clear: improved efficiency, reduced waste, and enhanced customer satisfaction. Implementing digital scanner technology is a strategic move for any automotive industry player aiming to streamline their painting processes and maintain high-quality standards in bumper paint matching.