Precision color matching in auto collision repair is an advanced art combining science and technology. Professionals use sophisticated tools like spectrophotometers and CAD software to accurately measure light interaction with metallic surfaces, ensuring perfect color harmony for complex finishes. This meticulous process not only restores aesthetics but also maintains structural integrity, maximizing vehicle value.

“Precision color matching is a critical aspect of achieving complex metallic finishes, demanding a deep understanding of both the material’s unique properties and advanced technological solutions. This intricate process involves accurately replicating colors across various metal substrates, addressing challenges posed by reflections, iridescence, and subtle variations in chemical compositions. In this article, we explore these nuances, delve into the difficulties encountered in achieving perfect color matching for metals, and uncover cutting-edge techniques and technologies that revolutionize precision color matching.”

- Understanding Precision Color Matching for Metallic Finishes

- Challenges in Achieving Accurate Color Matching for Metals

- Techniques and Technologies for Perfect Precision Color Matching

Understanding Precision Color Matching for Metallic Finishes

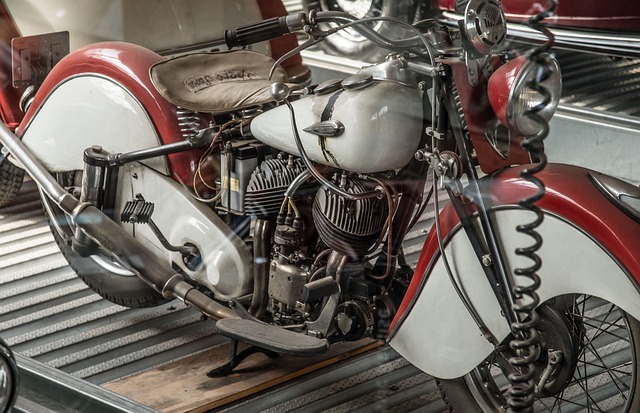

Precision color matching is a meticulous process that ensures complex metallic finishes accurately replicate their original hues. This is particularly crucial in auto collision repair, where restoring a vehicle’s exterior to its pre-accident condition demands exceptional attention to detail. In the realm of auto repair services and auto maintenance, achieving precise color matching goes beyond mere aesthetics; it guarantees structural integrity and enhances the overall value of the vehicle.

For professionals, this involves studying intricate color formulations, understanding how light interacts with metallic surfaces, and utilizing advanced tools to mix and apply paint with laser-like accuracy. The goal is to match not just the base color but also the subtle nuances created by reflections and imperfections found on these complex finishes. This level of precision is what transforms a mere repair into a restoration, ensuring that the vehicle not only looks like new but retains its original glossy finish.

Challenges in Achieving Accurate Color Matching for Metals

Achieving precise color matching for complex metallic finishes presents a unique set of challenges. Unlike traditional paint jobs with solid or matte finishes, metals offer a vast spectrum of reflections and iridescences due to their intricate microstructures. This complexity makes it difficult for color-matching algorithms to accurately replicate a metal’s unique appearance, especially when damaged or aged. Even the slightest variation in lighting conditions can dramatically alter how a metallic finish appears, making perfect matching an elusive goal.

In the realm of auto dent repair and car body repair, where precision color matching is crucial, these challenges are amplified. Collision centers strive to restore vehicles to their pre-incident condition, including replicating the exact metallic finish. However, factors like environmental conditions, paint aging, and even subtle differences in blending techniques can introduce variations that are often imperceptible to the untrained eye but detrimental to the overall aesthetic of a repaired vehicle.

Techniques and Technologies for Perfect Precision Color Matching

Achieving perfect precision color matching for complex metallic finishes is a delicate art that combines advanced techniques and cutting-edge technologies. In the realm of automotive repair, where every detail matters, professionals employ state-of-the-art equipment to ensure seamless color harmony on vehicles undergoing frame straightening or comprehensive car paint services.

One key technology driving this precision is the use of spectrophotometers, which measure light absorption and reflectance with incredible accuracy. These devices enable technicians to take detailed color readings, allowing for exact matching across various shades and finishes. Additionally, computer-aided design (CAD) software assists in digital color mixing and simulation, giving clients a clear visual of the final result before any paint is applied. This technology, coupled with skilled hands, ensures that every vehicle leaves the workshop with a flawless, metallic finish that meets or exceeds expectations.

Precision color matching for complex metallic finishes is a meticulous art that combines scientific understanding with advanced technologies. By overcoming challenges like color variation across different substrates and lighting conditions, professionals can now achieve flawless results. Through innovative techniques such as spectrophotometry and digital color management, the process has become more efficient and precise, ensuring that every metallic finish meets exacting standards. This advancement not only enhances aesthetic appeal but also solidifies precision color matching as a game-changer in the industry, allowing for consistent, vibrant, and durable finishes across various applications.