Advanced 3D scanning technologies have revolutionized collision frame repair, replacing manual, error-prone inspections with precise digital models. This game-changing approach enhances accuracy, speeds up repairs, identifies hidden damage, ensures structural integrity, improves safety, reduces costs, and cuts turnaround times. By leveraging laser or camera-based 3D data capture, auto body shops can achieve unprecedented precision, efficiency, and quality in repairing damaged car frames, panels, and components, setting new standards for the industry.

The evolution of structural scanning technology has revolutionized collision frame repair, marking a significant shift from traditional methods. This advanced process utilizes sophisticated sensors and 3D imaging to accurately assess damage, providing an unparalleled level of precision. By identifying hidden or hard-to-reach issues, structural scanning enhances safety for technicians while streamlining repair times. With key advancements in technology, the future looks bright for collision frame repair, promising even greater efficiency through AI integration, advanced 3D imaging, and remote scanning solutions.

- The Evolution of Structural Scanning Technology

- – Brief history of structural scanning in automotive repair

- – Key advancements that have improved collision frame repair

The Evolution of Structural Scanning Technology

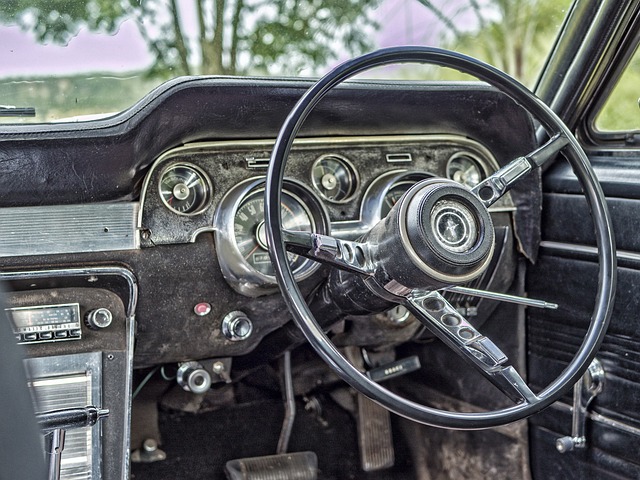

The evolution of structural scanning technology has revolutionized collision frame repair, enabling automotive repair shops to achieve unprecedented precision and efficiency. Historically, manual inspections and measurements were the norm, prone to human error and time-consuming. However, advancements in 3D laser scanning and advanced imaging technologies have changed the game. Today, body shop services utilize highly sophisticated equipment to capture detailed digital models of vehicle frames, allowing for a thorough analysis of damage and deformations. This technological leap has not only enhanced the accuracy of collision frame repair but also sped up the entire process, from assessment to reconstruction.

Incorporating structural scanning into automotive repair practices offers numerous benefits, including improved safety, reduced costs, and faster turnaround times. By swiftly identifying hidden damage, especially in complex cases involving crumpled or bent frames, technicians can tailor their restoration efforts precisely. Moreover, these digital solutions play a pivotal role in ensuring the structural integrity of vehicles post-repair, enhancing road safety for all. This technological advancement is a game-changer in the automotive industry, transforming traditional body shop services and raising the bar for tire services as well.

– Brief history of structural scanning in automotive repair

Structural scanning has evolved from a niche tool to an indispensable component in the modern automotive repair landscape, particularly in collision frame repair. Historically, before advanced technology, auto body shops relied heavily on manual measurements and visual inspection for aligning car frames after accidents or damage. This process was time-consuming, prone to human error, and often resulted in less accurate repairs.

The introduction of structural scanning systems has revolutionized collision center operations. These cutting-edge tools use laser or camera technology to capture precise 3D data of vehicle damage, enabling repair shops to accurately assess and measure car frames, panels, and components. This capability has transformed the way collision repair shops operate, fostering higher levels of efficiency and precision in their work, ultimately leading to better quality car damage repair outcomes.

– Key advancements that have improved collision frame repair

The field of collision frame repair has witnessed significant advancements over the years, revolutionizing how auto accidents are addressed. One of the key drivers of this transformation is the integration of advanced scanning technologies. Modern structural scanners offer precise measurements and detailed digital models of vehicle frames, allowing for more accurate assessments and tailored repairs. These tools have substantially improved the efficiency and quality of collision frame repair services.

Additionally, advancements in materials science and manufacturing techniques have played a crucial role. Newer, lighter, yet stronger metals and alloys are now used in modern vehicles, enhancing structural integrity and reducing overall weight. This, coupled with sophisticated welding and fabrication methods, ensures that vehicles not only look as good as new but also perform optimally after collision repair services. The combination of advanced scanning, improved materials, and meticulous craftsmanship has elevated the standards of collision frame repair, providing better outcomes for both vehicle owners and the automotive industry at large.

Structural scanning technology has revolutionized collision frame repair, offering unprecedented precision and efficiency. Advancements in sensor accuracy, data analysis software, and handheld devices have transformed the way automotive professionals address complex frame damage. By providing detailed digital representations of vehicle structures, these innovations enable more effective repairs, ensuring vehicles meet safety standards while minimizing material waste. As structural scanning continues to evolve, its integration into collision frame repair processes will only grow more vital, promoting higher quality outcomes across the industry.