Electric vehicles (EVs) are transforming transportation, but maintaining their structural integrity is vital for safety and performance. Auto body shops, equipped with modern tools and trained technicians, play a key role in structural integrity restoration, addressing frame damage from battery systems and electric motors. This meticulous process includes inspections, precision welding, collision repair, and alignment to meet stringent standards, extending vehicle lifespans and promoting cost-effectiveness and environmental sustainability. Advanced technologies and innovative repair methods are emerging to keep pace with growing EV demand, contributing to a greener future for electric mobility.

In today’s electric vehicle (EV) revolution, ensuring structural integrity is paramount. This article delves into the critical aspect of restoring EV frames, a crucial step in maintaining safety and performance. We explore the intricacies of understanding structural integrity in these vehicles and unravel the process of effective restoration. From advanced techniques to the numerous benefits, including cost savings and environmental advantages, we provide insights into the future outlook for EV frame restoration, highlighting its growing importance in the evolving automotive landscape.

- Understanding Structural Integrity in Electric Vehicles

- The Process of Structural Integrity Restoration

- Benefits and Future Outlook for EV Frame Restoration

Understanding Structural Integrity in Electric Vehicles

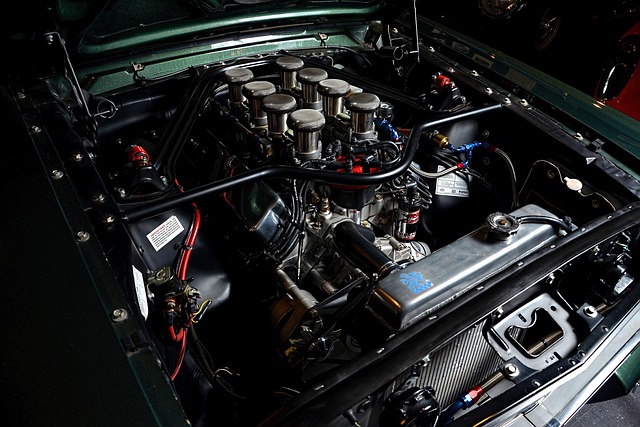

Electric vehicles (EVs) are transforming the automotive landscape, offering advanced technology and environmental benefits. However, ensuring their structural integrity is paramount to maintaining safety and performance. Structural integrity refers to the overall stability and strength of a vehicle’s frame, which bears the brunt of impacts and supports the entire structure. In EVs, this becomes even more critical due to the placement of high-voltage batteries and other sensitive components.

Restoring structural integrity in EV frames involves specialized techniques and knowledge. Auto body shops and auto repair shops equipped with advanced equipment and trained technicians play a vital role. They use modern diagnostic tools to assess frame damage, often caused by accidents or wear over time. Through precision welding, replacement of damaged sections, and careful alignment, these professionals bring the vehicle back to its original structural soundness, ensuring it meets safety standards and providing a reliable foundation for continued EV operation.

The Process of Structural Integrity Restoration

The process of Structural Integrity Restoration for Electric Vehicle (EV) frames involves a meticulous approach to ensure safety and optimal performance. It begins with a thorough inspection to identify any damage or weaknesses in the frame structure, which is critical as EV frames bear the weight of advanced battery systems and electric motors. Advanced diagnostic tools are employed to pinpoint problem areas, ensuring that every component is assessed for integrity.

Repairs often encompass a combination of techniques, including paintless dent repair for minor cosmetic dents and dings, and collision repair for more significant structural issues. Auto glass repair may also be necessary if the frame’s protective barriers have been compromised. The goal is to restore the EV’s structural integrity while adhering to stringent safety standards, ultimately extending the vehicle’s lifespan and maintaining its performance capabilities.

Benefits and Future Outlook for EV Frame Restoration

The benefits of structural integrity restoration for electric vehicle (EV) frames are significant, addressing a critical aspect of EV ownership and maintenance. As EVs gain popularity, ensuring the long-term safety and performance of their frames becomes increasingly essential. Restoration techniques not only enhance the structural stability of the vehicle but also extend its lifecycle, potentially reducing costs for owners. By repairing and reinforcing damaged or weakened areas, rather than replacing the entire frame, restoration practices promote sustainability and minimize environmental impact. This is particularly important given the resource-intensive nature of EV manufacturing.

Looking ahead, the future outlook for EV frame restoration is promising as the industry continues to evolve. Advanced technologies and innovative repair methods are being developed to enhance the precision and effectiveness of restoration processes. These advancements promise improved outcomes and greater accessibility to car paint services and auto body shop capabilities, ensuring that collision centers can keep pace with the growing demand for EV maintenance and repairs. This shift towards more sustainable and cost-effective solutions will contribute to a greener future for electric mobility.

Structural integrity restoration for electric vehicle (EV) frames is a game-changer in the automotive industry. As EV technology continues to evolve, ensuring the structural soundness of these vehicles is paramount. The process involves meticulous techniques and advanced materials to repair and reinforce damaged frames, extending the lifespan of EVs and enhancing their safety features. With the growing demand for sustainable transportation, the benefits of EV frame restoration are evident, promising a more eco-friendly and cost-effective future for both vehicle owners and manufacturers alike.