Mercedes Boron steel cutting is a specialized process using advanced techniques for precise cutting and shaping high-performance alloy with superior strength-to-weight ratio and durability, ideal for modern vehicle body restoration and collision repair. Its hardiness, corrosion resistance, and compatibility with safety systems extend component lifespans while maintaining structural integrity and meeting stringent safety standards. This innovation is crucial in enhancing passenger protection during collisions and enabling efficient dent removal, making it a game-changer in the automotive industry.

Mercedes boron steel cutting, a revolutionary material, combines exceptional strength and durability with enhanced safety features. This advanced steel type has gained prominence in the automotive industry for its compatibility with modern crash-avoidance systems. With its unique properties, it plays a vital role in enhancing vehicle safety without compromising structural integrity. Explore how Mercedes boron steel cutting’s ability to withstand extreme forces contributes to safer driving experiences and continues to shape the future of automotive engineering.

- Understanding Mercedes Boron Steel Cutting: Properties and Advantages

- Compatibility with Modern Safety Systems: A Comprehensive Look

- Real-World Applications: Why This Metal is Essential in Today's Vehicles

Understanding Mercedes Boron Steel Cutting: Properties and Advantages

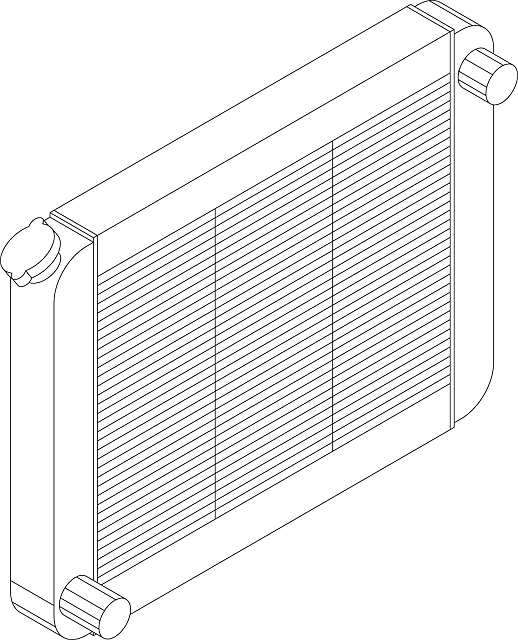

Mercedes Boron steel cutting is a specialized process that utilizes advanced techniques to precisely cut and shape this high-performance alloy. This steel, known for its exceptional strength-to-weight ratio and durability, is increasingly popular in modern vehicle construction, particularly in car body restoration and collision repair applications. Its superior properties make it ideal for creating intricate parts with tight tolerances, ensuring structural integrity and safety in vehicles.

The advantages of Mercedes Boron steel cutting are multifaceted. This material’s hardness and resistance to corrosion contribute to longer-lasting components, reducing the need for frequent replacements. Additionally, its compatibility with modern safety systems is a significant benefit. Whether it’s high-precision cuts required for car restoration or precise repairs after a collision, Mercedes boron steel cutting offers a reliable solution that maintains structural integrity while aligning with stringent safety standards.

Compatibility with Modern Safety Systems: A Comprehensive Look

Mercedes boron steel cutting is a game-changer in the automotive industry, offering unparalleled precision and durability for modern vehicle manufacturing. This advanced material’s compatibility with today’s safety systems is a critical aspect that sets it apart from traditional steels. With advancements in car design and safety standards, ensuring that cutting tools can handle the unique properties of boron steel without compromising structural integrity is essential.

The seamless integration of Mercedes boron steel cutting into auto body repair processes allows for efficient dent removal and precise shaping, which are vital for addressing various types of car damage repair. Its superior strength-to-weight ratio means that components made from this steel can withstand rigorous safety tests while maintaining their structural integrity. This is particularly relevant in the event of collisions, where the ability to absorb and distribute energy is crucial for passenger protection.

Real-World Applications: Why This Metal is Essential in Today's Vehicles

In today’s automotive landscape, Mercedes boron steel cutting plays a pivotal role in vehicle manufacturing and safety. This advanced metal is not just a choice for luxury car brands like Mercedes; it’s an essential component that enhances structural integrity and contributes to modern safety systems. Its high-strength properties make it ideal for critical components such as frames, chassis, and even panels in auto body repair, ensuring the vehicles can withstand severe impacts while protecting occupants.

The integration of boron steel in automotive design allows for lighter yet stronger structures, which is crucial for improving fuel efficiency and reducing overall vehicle weight. When a car suffers damage, specifically in bumper repair scenarios, the ability to seamlessly cut and shape boron steel ensures that repairs are both effective and efficient, maintaining the structural integrity and safety features that modern vehicles rely on. This metal’s compatibility with advanced safety systems makes it an indispensable material in today’s auto industry, shaping not just cars’ physical attributes but also their safety standards.

Mercedes Boron steel cutting stands as a game-changer in modern automotive manufacturing, offering enhanced safety without compromising structural integrity. Its unique properties and compatibility with advanced safety systems make it an essential material for today’s vehicles, ensuring both performance and passenger protection. By leveraging the advantages of Mercedes Boron steel, automakers can create lighter, safer, and more efficient cars, solidifying its position as a key component in the industry’s ongoing evolution.