PDR (Paintless Dent Repair) is a revolutionary automotive technique for repairing steel panels on modern cars without painting or replacing parts, preserving durability and restoring original appearance. Effective PDR materials for steel mimic metal's flexibility and resilience, offering high ductility and strong adhesion to withstand daily driving conditions. Choosing the right flexible polymers designed for metal surfaces ensures superior aesthetic results, especially for complex dents or curved panels, enhancing vehicle resale value compared to traditional painting methods.

“Uncover the transformative power of Material Selection in PDR (Paint Damage Repair) specifically tailored for steel panels. This comprehensive guide delves into the art and science behind restoring steel surfaces to their pristine condition. From understanding the PDR process and its applications on steel, to exploring the chemical composition crucial for effective repair, this article provides an insightful journey.

We’ll navigate the key factors in choosing materials, offering a detailed guide to ensure optimal results. Discover how the right materials can revolutionize your PDR practice.”

- Understanding PDR and Its Application on Steel Panels

- The Science Behind Effective Materials for PDR

- Choosing the Right Materials: A Comprehensive Guide

Understanding PDR and Its Application on Steel Panels

PDR, or Paintless Dent Repair, is a cutting-edge technique revolutionizing the way vehicle damage is addressed, particularly for steel panels. This non-invasive method has gained significant traction in the automotive industry as an efficient and cost-effective solution for collision centers and vehicle body shops. By utilizing specialized tools and techniques, PDR allows professionals to remove dents, dings, and creases from metal surfaces without painting or replacing parts, which can save time and money.

In the context of steel panels, PDR is especially valuable due to the material’s inherent properties. Steel is known for its durability and strength, making it a popular choice in modern vehicles. However, these same attributes can make traditional repair methods more challenging. PDR offers a gentle approach, allowing collision repair services to restore the original appearance of steel panel surfaces while preserving their structural integrity. This innovative process has become a game-changer in the industry, providing vehicle owners with an alternative to lengthy and costly repairs at a fraction of the time and expense of conventional methods.

The Science Behind Effective Materials for PDR

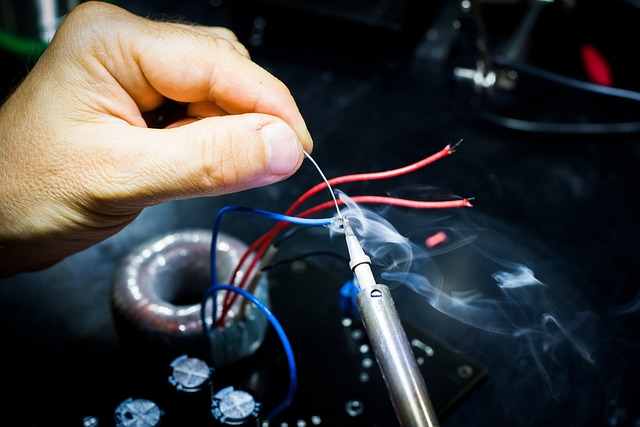

The effectiveness of Material in PDR (Paintless Dent Repair) for steel panels lies in their unique properties and ability to mimic the metal’s natural behavior. PDR is a specialized auto body service that repairs dents and scratches without painting, focusing on preserving the original finish. The science behind it involves understanding the flexibility and resilience of materials used. Effective PDR materials for steel panels should possess high ductility, allowing them to return to their original shape after being pressed or pulled, just like the metal itself.

This characteristic ensures that the dent is effectively removed, leaving minimal if any trace of damage. Additionally, these materials must have excellent adhesion properties to bond securely with the steel panel’s surface while also withstanding the rigors of daily driving and environmental conditions. The right combination of flexibility and strong bonding capabilities makes certain materials ideal for PDR, offering a cost-effective and efficient solution in auto body repair compared to traditional painting methods, thus enhancing vehicle aesthetics and resale value in the process.

Choosing the Right Materials: A Comprehensive Guide

Choosing the right materials for PDR (Paintless Dent Repair) on steel panels is a critical step in ensuring the effectiveness and longevity of the repair process. When it comes to PDR for steel panels, understanding the properties and compatibility of materials is essential. For instance, selecting high-quality, flexible polymers suitable for metal surfaces can significantly improve the outcome, especially when dealing with complex dents or curves on the panel. These materials offer the necessary pliability to conform to the panel’s shape while providing excellent adhesion and durability.

In the context of a professional auto repair shop or body shop services, tire services providers should opt for materials designed specifically for metal applications. This ensures that the repair not only looks seamless but also withstands the rigors of daily use. The right choice can make all the difference, ensuring the restoration of your steel panel to its pre-dent condition, much like a tire service expert would ensure optimal performance through the use of suitable tire products.

PDR (Paintless Dent Repair) has transformed the way we restore steel panels, offering a non-invasive solution that preserves the original finish. Choosing the right materials is key to effective PDR, with options ranging from polyurethanes to specialized dent removal gels. By understanding the science behind these materials and following a comprehensive guide for selection, technicians can achieve superior results in PDR for steel panels, ensuring a seamless and durable repair that meets the highest standards.