Tesla's Model S and X cars utilize structural aluminum for lightweight, strong construction, but their specialized repair requires advanced equipment and experienced technicians due to intricate design and interconnected systems. The meticulous process involves thorough inspection, careful disassembly, metal reshaping, replacement/reinforcement, and precise reassembly using high-strength adhesives, ensuring both cosmetic perfection and continued optimal vehicle performance comparable to collision centers.

“Discover the intricacies of Tesla structural aluminum repair, a specialized process crucial for preserving the integrity and aesthetics of Model S and X vehicles. This article delves into the unique materials and design considerations that set Tesla apart, exploring common issues faced during repairs.

We’ll guide you through the intricate process, highlighting best practices to ensure structural aluminum repairs are done effectively, maintaining the superior quality and performance expected from Tesla vehicles.”

- Understanding Tesla Structural Aluminum: Materials and Design

- Common Issues and Challenges in Repairing Model S and X

- The Process of Effective Structural Aluminum Repair for Tesla Vehicles

Understanding Tesla Structural Aluminum: Materials and Design

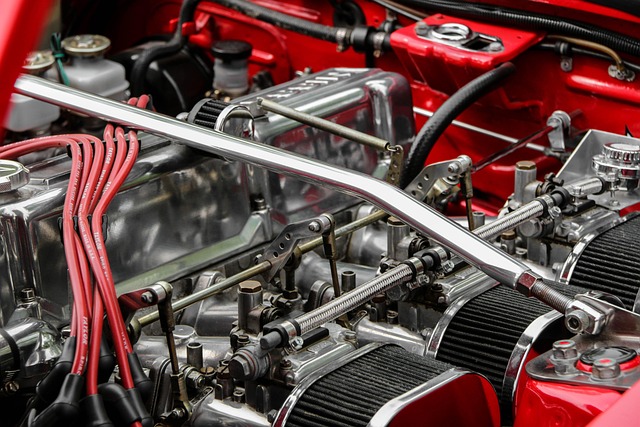

Tesla’s use of structural aluminum in their Model S and X vehicles represents a significant advancement in automotive design. This lightweight yet robust metal is strategically employed to enhance performance, efficiency, and overall vehicle dynamics. In contrast to traditional steel frames, Tesla’s aluminum architecture allows for greater design flexibility, enabling streamlined profiles and reduced weight. Every component, from the chassis to body panels, contributes to a stronger, more rigid structure that offers superior crash protection without adding substantial mass.

Understanding the intricate design of Tesla structural aluminum repair is crucial when addressing any damage or misalignments. Unlike mere cosmetic fixes, these repairs demand precise knowledge of material properties and engineering principles to maintain the vehicle’s structural integrity. Just as a skilled auto body restorer would approach a Mercedes-Benz repair with meticulous care, the same level of expertise is required to handle Tesla’s advanced aluminum frames. This ensures that the vehicle not only looks like new but also performs optimally on the road.

Common Issues and Challenges in Repairing Model S and X

In the case of Tesla Model S and X vehicles, structural aluminum repair presents both unique advantages and challenges. One of the primary issues is the specialized nature of the material itself. While aluminum is lightweight and corrosion-resistant, it can be difficult to weld and fabricate compared to traditional steel body panels. This requires auto repair services with advanced equipment and experienced technicians who understand Tesla’s specific manufacturing processes.

Additionally, these electric vehicles often involve intricate, interconnected systems within their bodies. Car repair services for Model S and X must not only address visible structural damage but also ensure that repairs do not interfere with the vehicle’s overall performance and technology suite. Finding a reputable auto repair shop equipped to handle both conventional and advanced repairs is crucial for maintaining the integrity and safety of these innovative vehicles.

The Process of Effective Structural Aluminum Repair for Tesla Vehicles

The process of effective Tesla structural aluminum repair for Model S and X vehicles involves a meticulous approach to ensure the safety and integrity of the car’s frame. It begins with a thorough inspection to identify the extent of damage, which can range from dents and dings to more significant structural breaches. Skilled technicians use advanced tools and techniques, such as laser measurements and computer-aided design (CAD) software, to precisely assess and plan the repair. This digital precision is crucial for accurate and seamless restoration.

Once the assessment is complete, the repair process commences with careful disassembly of affected components, allowing access to the damaged aluminum panels. Specialized techniques like heat application and mechanical manipulation are employed to reshape and realign the metal without compromising its strength. After replacement or reinforcement of any necessary parts, the panels are carefully reassembled and secured using advanced bonding adhesives designed for high-strength aluminum repair. This meticulous process ensures that the Tesla vehicle not only looks as good as new but also maintains its structural integrity, comparable to services provided by a reputable collision center.

Tesla’s innovative use of structural aluminum in their Model S and X presents both unique challenges and opportunities for repair. By understanding the material’s properties and common issues, specialized repairs can effectively restore these vehicles to their original integrity and performance. A meticulous process involving advanced techniques and precise tools ensures a robust and lasting solution for Tesla structural aluminum repair.