Spot weld bonding repair is a specialized auto restoration technique for roof and quarter panels, emphasizing precision and quality in Mercedes Benz repair. This method creates strong adhesive bonds without disturbing surrounding areas, effectively filling gaps and reinforcing weak bonds to restore structural stability. Preferred in modern car body shops due to its cost-effectiveness and minimal metalworking requirements, it's an eco-friendly and time-efficient solution for damaged rooflines or quarter panels, maintaining structural integrity while offering efficiency, aesthetic appeal, and affordability, despite the challenges of matching original weld strength and selecting appropriate agents.

“Discover the art of spot weld bonding repairs for your vehicle’s roof and quarter panels. This comprehensive guide delves into the intricacies of this specialized technique, offering a reliable solution for structural integrity. We explore the process, from understanding the method to mastering its application.

Learn about the benefits that make spot weld bonding repair a game-changer in automotive restoration. Additionally, we highlight common challenges and provide insights to ensure successful outcomes. Get ready to transform your vehicle’s exterior with this robust repair approach.”

- Understanding Spot Weld Bonding Repairs

- The Process of Repair for Roof and Quarter Panels

- Benefits and Common Challenges in Spot Weld Bonding Repair

Understanding Spot Weld Bonding Repairs

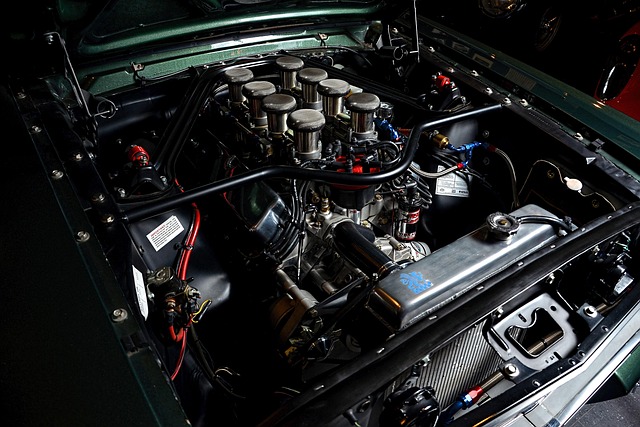

Spot weld bonding repairs are a specialized technique used to fix or reinforce weak spots in vehicle panels, particularly in roofs and quarter panels. This process is crucial for auto dent repair and maintaining structural integrity in car body shops. Unlike traditional welding methods that join metal pieces directly, spot weld bonding involves creating a strong adhesive bond between existing welds or metal surfaces without disrupting the surrounding area.

In Mercedes Benz repair, where precision and quality are paramount, spot weld bonding repairs offer an efficient solution for damaged rooflines or quarter panels. By strategically applying specialized adhesives, technicians can effectively fill gaps, reinforce weak bonds, and restore structural stability. This method is not only cost-effective but also minimizes the need for extensive metalworking, making it a preferred choice in modern car body shops focusing on eco-friendly and time-efficient repairs.

The Process of Repair for Roof and Quarter Panels

The process of repairing roof and quarter panels using spot weld bonding is a meticulous art within the realm of auto repair services. It begins with identifying the extent of damage, whether from impact or corrosion. Once determined, the affected area is prepared by removing any loose debris, and in some cases, correcting misaligned panel edges for a seamless finish. Auto dent repair techniques may be employed to shape and mold the panels back to their original form.

After preparation, skilled technicians apply a specialized adhesive designed for robust bonding. This adhesive fills gaps and ensures a strong connection between the damaged panel and the surrounding body. The spot welds are then carefully executed, strategically placed to mimic the original manufacturing process. This meticulous approach, often coupled with careful sanding and priming, facilitates an unnoticeable repair that blends seamlessly into the car restoration process, enhancing the vehicle’s overall aesthetics and structural integrity.

Benefits and Common Challenges in Spot Weld Bonding Repair

Spot weld bonding repairs offer a range of benefits for both car restoration and fender repair projects. This technique is particularly advantageous when dealing with roof and quarter panel damage, as it provides a strong and lasting bond. The process ensures that the original structure is maintained, preserving the integrity of the vehicle’s overall design. Moreover, spot weld bonding repairs are efficient, cost-effective, and can restore vehicles to their pre-damaged condition, enhancing their aesthetic appeal and structural soundness.

Despite these advantages, there are common challenges associated with spot weld bonding repair. Auto repair services often face difficulties in matching the original weld strength, especially when working on older vehicles or those with complex panel designs. The precision required to accurately target specific weld points without impacting adjacent areas can be demanding. Additionally, ensuring the proper preparation of the metal surface and choosing the right bonding agents are critical for successful long-term results, adding complexity to the process.

Spot weld bonding repairs offer an effective solution for damaged roof and quarter panels, providing both structural integrity and aesthetic restoration. By understanding the process and addressing common challenges, auto body shops can deliver high-quality, long-lasting results. This specialized technique, centered around spot weld bonding repair, not only enhances vehicle safety but also contributes to the overall retention of a vehicle’s value.