Repair Specification Compliance in auto workshops is crucial for high-quality standards. This requires staff training in advanced techniques and technologies to interpret and implement detailed repair specifications accurately. Auto shops must invest in continuous education, industry trends updates, and practical skills development to meet compliance. Regular assessments, feedback, and digital quality control systems further ensure precise repairs, customer satisfaction, and adherence to repair specification standards.

In the competitive marketplace, ensuring repair specification compliance is paramount for shops to maintain customer satisfaction and trust. This article explores critical steps that automotive service centers take to meet stringent repair specifications. We delve into defining quality standards, implementing tailored training programs for technicians, and adopting robust continuous monitoring and quality assurance practices. By adhering to these strategies, shops can guarantee precise repairs, enhance operational efficiency, and foster long-term customer relationships.

- Understanding Repair Specifications: Defining Quality Standards

- Implementing Effective Training Programs for Technicians

- Continuous Monitoring and Quality Assurance Practices

Understanding Repair Specifications: Defining Quality Standards

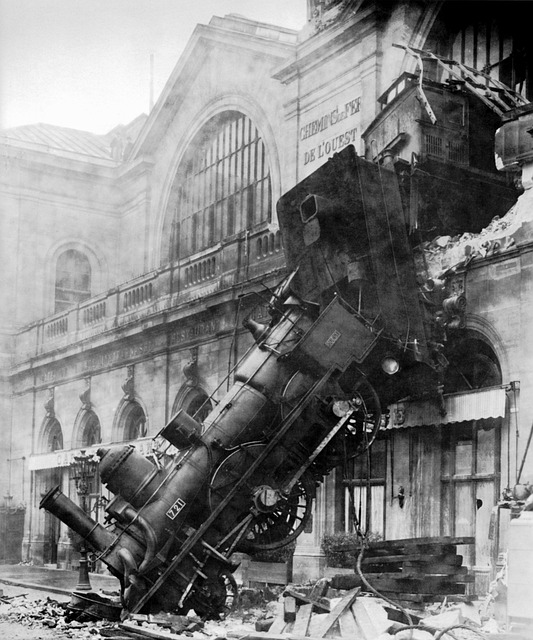

In the realm of automotive services, understanding repair specifications is paramount for shops aiming to achieve repair specification compliance. These specifications define the quality standards and procedures for various types of car damage repair, car body repair, and car collision repair. By adhering strictly to these guidelines, workshops ensure that repairs not only meet but exceed industry expectations. Every detail, from panel fitment to paint accuracy, is meticulously specified to guarantee customer satisfaction and vehicle safety.

Shops must invest in comprehensive training for their staff to interpret and implement these specifications accurately. This involves learning the latest techniques in car body repair, understanding advanced painting technologies, and mastering precision measurements. Through continuous education, technicians become adept at navigating the intricate processes required to maintain repair specification compliance, ultimately fostering a reputation for excellence within the industry.

Implementing Effective Training Programs for Technicians

To ensure repair specification compliance, steps must be taken to equip technicians with the necessary knowledge and skills. Implementing effective training programs is a strategic move that addresses this need. These programs should cover not just theoretical aspects but also hands-on practice, focusing on the latest industry standards and technologies related to auto bodywork, automotive collision repair, and car body restoration. By providing continuous learning opportunities, shops can maintain a competent workforce capable of accurately interpreting and executing complex repair specifications.

Well-structured training sessions enable technicians to stay updated with evolving regulations and best practices in their field. This ensures that every repair job undertaken adheres to the specified standards, thereby enhancing customer satisfaction and retention. Through regular assessments and feedback mechanisms within these programs, shops can identify knowledge gaps and tailor training accordingly, fostering a culture of continuous improvement aligned with repair specification compliance goals.

Continuous Monitoring and Quality Assurance Practices

In the dynamic landscape of automotive services, maintaining strict adherence to repair specifications is non-negotiable for car body shops. Continuous monitoring and quality assurance practices form the backbone of this commitment. Skilled technicians employ sophisticated tools and techniques to ensure every repair, from vehicle paint repair to intricate auto dent repair, aligns perfectly with the original manufacturer’s standards. This meticulous process involves regular training sessions, where staff are updated on the latest industry benchmarks and best practices.

Additionally, advanced quality control systems are integrated into the workflow of these shops. These digital tools facilitate real-time data analysis, enabling quick identification and correction of any deviations from the prescribed repair specifications. Such proactive measures not only uphold the integrity of repairs but also foster customer satisfaction, ensuring that every car body shop delivers top-tier services that meet and exceed expectations for both vehicle paint repair and comprehensive car body repair solutions.

In ensuring repair specification compliance, steps such as understanding clear quality standards, providing comprehensive training, and adopting rigorous monitoring practices are paramount. By defining precise repair specifications and implementing effective training programs, shops can equip their technicians with the knowledge and skills to consistently deliver high-quality work. Continuous monitoring and robust quality assurance practices further solidify this commitment, ensuring that every repair meets or exceeds expected standards. These strategies not only foster customer satisfaction but also strengthen a shop’s reputation in an industry where repair specification compliance is non-negotiable.