The post-repair inspection process is a critical quality control step in auto body shops, ensuring repairs meet pre-accident standards. Trained technicians conduct visual inspections with advanced 3D measuring devices to verify dimensions and alignment. A test drive confirms drivability and customer satisfaction. Future inspections will leverage technology like imaging software, 3D scanning, and AI analysis for enhanced precision and efficiency, streamlining the process, improving communication, reducing errors, and boosting customer satisfaction. Digital tools like AI algorithms and augmented reality (AR) can also enable remote inspections and predict issues, setting new benchmarks for excellence in car restoration.

The post-repair inspection process in auto body shops is evolving to meet the demands of a modern, tech-driven world. As consumers expect swift and precise repairs, understanding and optimizing this critical stage is crucial for shop efficiency and customer satisfaction. This article delves into the intricacies of the current post-repair inspection process, explores how technology is revolutionizing inspections, and highlights future trends in quality assurance to ensure top-tier vehicle restoration.

- Understanding the Current Post-Repair Inspection Process

- Embracing Technology: Digital Tools for Efficient Inspections

- Streamlining Quality Assurance: Best Practices and Future Trends

Understanding the Current Post-Repair Inspection Process

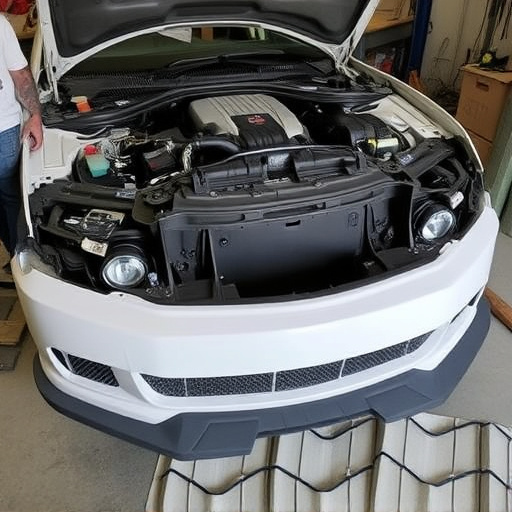

The post-repair inspection process is a critical stage in auto body shops, serving as a quality control measure for collision repair and auto dent repair services. Currently, this process involves several steps that ensure the meticulous restoration of car bodywork to its pre-accident condition. It begins with a thorough visual inspection by trained technicians who meticulously examine every angle and detail of the repaired area. This initial assessment is crucial in identifying any discrepancies or imperfections that may have occurred during the repair process.

Technicians then employ advanced tools, such as 3D measuring devices, to precisely compare the dimensions of the damaged and repaired sections. This ensures accurate alignment and fit, especially in complex car bodywork shapes. The final step involves a test drive to assess the vehicle’s performance, handling, and overall drivability, solidifying the successful completion of the collision repair and ensuring customer satisfaction.

Embracing Technology: Digital Tools for Efficient Inspections

The future of post-repair inspection in auto body shops is intertwined with technology, revolutionizing the way repairs are assessed and ensuring top-notch quality. Digital tools offer a new level of precision and efficiency, transforming traditional manual inspections. With advanced imaging software, 3D scanning, and AI-powered analysis, auto body painting and restoration processes become more accurate and time-effective. These technologies enable detailed visual assessments, allowing technicians to detect even the subtlest imperfections in car body restoration work.

By implementing these digital solutions, auto collision centers can streamline their post-repair inspection process. Real-time data and comprehensive reporting enhance communication between repair teams and customers, fostering trust. Moreover, advanced technology reduces the likelihood of human error, ensuring every car that leaves the shop meets the highest standards. This not only improves customer satisfaction but also contributes to building a reputation for excellence in auto body painting services.

Streamlining Quality Assurance: Best Practices and Future Trends

The post-repair inspection process is a critical stage in any auto body shop, ensuring that cars leave the facility with flawless auto body work and adhering to high-quality standards. Streamlining this process is not just about efficiency; it’s about maximizing customer satisfaction and minimizing errors. Best practices include implementing digital inspection tools for detailed record-keeping, standardized checklists for consistency, and real-time feedback mechanisms between technicians and inspectors.

Looking ahead, future trends in quality assurance aim to further automate and digitize the post-repair inspection process. Advanced AI and machine learning algorithms can analyze repair data to predict potential issues, while augmented reality (AR) tools enable remote inspections, enhancing accessibility and reducing labor costs. As auto body shops embrace these innovations, they’ll not only elevate their service offerings but also set new benchmarks for excellence in car restoration, ensuring a seamless transition from repair to flawless completion.

The future of post-repair inspections in auto body shops lies in digital transformation. By embracing innovative technology, such as advanced imaging and AI-powered software, these processes can become faster, more accurate, and less labour-intensive. Streamlining quality assurance through standardized protocols and automated reporting will not only enhance efficiency but also ensure consistent, high-quality repairs. As the auto industry continues to evolve, adopting these cutting-edge practices will be key for body shops to stay competitive and meet the growing demands of modern vehicle owners.