Squeeze-type resistance spot welding is a revolutionary method for auto body repair, combining pressure and high-energy pulses to create strong, precise bonds between metal components. This advanced technique offers superior repair quality, minimal distortion, and improved paint adhesion, ensuring structural integrity and longevity in vehicle maintenance. Ideal for complex repairs, it revitalizes vehicles with unnoticeable differences in integrity, enhancing safety and corrosion protection.

In the realm of automotive repairs, understanding advanced welding techniques can significantly enhance long-term structural integrity. This article delves into the benefits of squeeze-type resistance spot welding, a powerful and precise method. By examining its unique advantages, we uncover why it excels in strengthening components, ensuring durability and safety. We explore its practical applications, highlighting its pivotal role in automotive restoration and its potential to revolutionize repair processes.

- Understanding Squeeze-Type Resistance Spot Welding: A Powerful Repair Technique

- Longevity and Strength: The Advantages of This Welding Method for Structural Integrity

- Practical Applications: Where and Why Squeeze-Type Spot Welds Excel in Automotive Repairs

Understanding Squeeze-Type Resistance Spot Welding: A Powerful Repair Technique

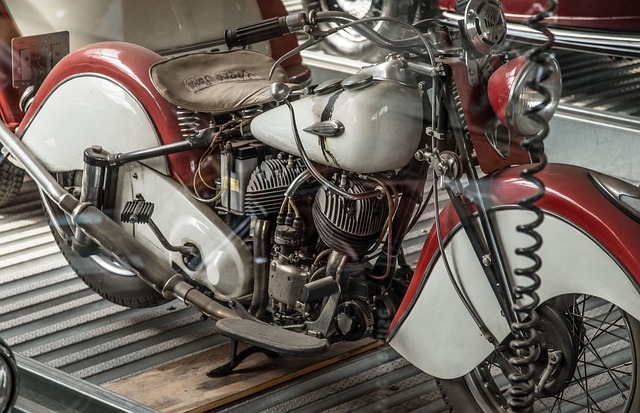

Squeeze-type resistance spot welding is a powerful technique that has revolutionized auto body work and repair processes. This advanced method involves using a specialized tool to apply significant pressure while simultaneously melting metal with a high-energy pulse. The result? A strong, permanent bond that enhances the structural integrity of vehicles, especially during complex repairs or when joining different metal components.

In the realm of auto maintenance, this welding technique offers numerous advantages. It’s particularly useful for repairing or replacing damaged panels, ensuring that the repair is as robust as the original manufacturing quality. The precision and control inherent in squeeze-type resistance spot welding make it an ideal choice for intricate auto body work, allowing for precise adjustments and minimal distortion of surrounding materials. This method also contributes to a more efficient auto painting process by providing a solid foundation, thereby ensuring better adhesion of paint or coating.

Longevity and Strength: The Advantages of This Welding Method for Structural Integrity

The longevity and structural integrity of a vehicle are significantly enhanced by employing squeeze-type resistance spot welding techniques in auto body work. This advanced welding method offers unparalleled strength, making it an excellent choice for repairing and reinforcing car bodies. The process involves precise pressure and heat application to create robust bonds, ensuring that the repaired area performs as well as the original factory welds.

In automotive body shops, where precision meets craftsmanship, squeeze-type spot welding has become a game-changer. It ensures that every joint is securely fastened, preventing structural weaknesses that could compromise safety and performance. This method is particularly beneficial for complex auto body repairs, ensuring that vehicles return to the road with unnoticeable differences in their structural integrity, a testament to the superior quality of car paint services and overall vehicle rejuvenation.

Practical Applications: Where and Why Squeeze-Type Spot Welds Excel in Automotive Repairs

In the realm of automotive repairs, squeeze-type resistance spot welding has emerged as a game-changer for professionals in auto collision centers and vehicle repair shops. This advanced technique is particularly valuable when it comes to ensuring long-term strength and structural integrity during car paint services. The practical applications are vast, from repairing damaged body panels to reinforcing welds on complex components.

Squeeze-type spot welding excels due to its ability to create strong, precise bonds with minimal heat input. This is especially beneficial for delicate metal surfaces often found in modern vehicles. By controlling the pressure and energy applied, welders can achieve superior penetration without causing excess thermal damage, a common issue in traditional welding methods. As a result, these welds exhibit enhanced fatigue resistance and corrosion protection, making them ideal for maintaining vehicle safety and structural integrity over extended periods.

In conclusion, squeeze-type resistance spot welding offers significant long-term strength benefits for structural integrity in repairs. Its advantages include superior longevity and exceptional mechanical properties, making it a game-changer in automotive repair applications. By understanding this powerful technique and its practical applications, professionals can ensure robust and durable solutions, enhancing the overall quality and safety of vehicle maintenance.