Electronic measuring equipment, from digital calipers to 3D scanners, is indispensable across multiple sectors, enhancing precision and efficiency where manual methods once prevailed. Digital micrometers excel in delicate repairs, while 3D measurement systems are vital for manufacturing quality control. Choosing the right equipment leads to optimal performance, accuracy, and cost savings in applications like car dent repair and complex fabrication. Digital tools, with their enhanced accuracy and advanced features, revolutionize industries such as auto body restoration, offering meticulousness and connectivity options that streamline workflows.

Unleash the full potential of your electronic measuring equipment with our advanced tips and techniques. In this comprehensive guide, we delve into the diverse world of analog and digital tools, exploring essential devices like multimeters, calipers, and oscilloscopes. Learn the art of calibration for impeccable accuracy, from regular checks to step-by-step guides for various equipment. Discover advanced strategies to minimize errors, maximize precision, and harness data logging, automated measurements, and connectivity for efficient data interpretation.

- Understanding Different Types of Electronic Measuring Equipment

- – Exploring various categories: analog vs digital

- – Highlighting common tools and their unique functionalities

Understanding Different Types of Electronic Measuring Equipment

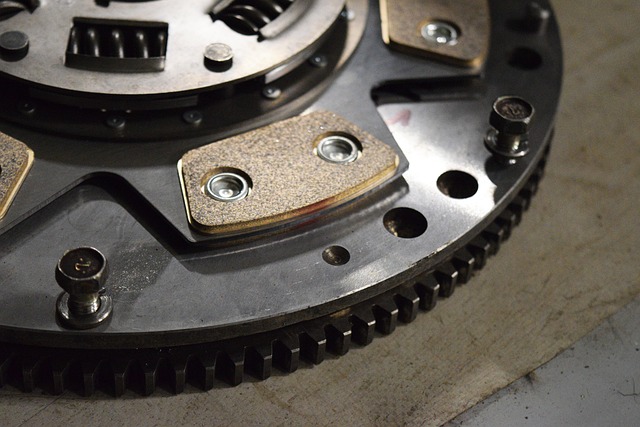

Electronic measuring equipment plays a pivotal role in various industries, offering precision and efficiency in tasks that once relied solely on manual measurement. From simple tools like digital calipers to complex systems such as 3D scanners, each type is designed for specific applications. For instance, in vehicle body repair, car dent repair, or even in manufacturing, the right electronic measuring equipment can significantly streamline processes and improve outcomes.

Understanding these devices involves grasping their functions and capabilities. Digital micrometers, for example, provide accurate length measurements down to microns, ideal for delicate car repair services or precision engineering. While 3D measurement systems capture detailed surface data, making them indispensable in quality control for both automotive production lines and intricate fabrication projects. Knowing which tool to use for the task at hand ensures efficiency, accuracy, and often, cost savings in tasks ranging from car dent repair to complex manufacturing processes.

– Exploring various categories: analog vs digital

When delving into the world of electronic measuring equipment, understanding the fundamental differences between analog and digital technologies is essential for accurate and efficient measurements. Analog devices, like traditional voltmeters and rulers, rely on physical movements or signals to display measurements, offering a tactile experience. While reliable, they may be less precise compared to their digital counterparts.

On the other hand, digital electronic measuring equipment leverages advanced circuitry and sensors to convert physical quantities into numerical data, displayed on an LCD or LED screen. This allows for enhanced precision, making it indispensable in fields such as car body restoration and auto collision centers where meticulous measurements are crucial for successful collision repair. Digital tools also often come equipped with additional features like data logging and connectivity options, streamlining workflows in these professional settings.

– Highlighting common tools and their unique functionalities

In today’s world, electronic measuring equipment has become an indispensable toolset for professionals across various industries, from precision engineering to auto repair services. Among the most common and versatile tools are digital calipers, multimeters, and laser distance meters. Digital calipers offer exceptional accuracy in measuring dimensions, making them invaluable for tasks requiring intricate detail work, such as fine mechanical repairs or vehicle body repair. Multimeters, on the other hand, serve as all-in-one solutions for voltage, current, and resistance testing, streamlining processes in auto repair and electrical work alike.

Laser distance meters provide a non-contact way to measure distances accurately, making them handy for everything from construction projects to vehicle paint repair. These tools are especially beneficial in settings like body shops where precise measurements are crucial for ensuring flawless finishes. By leveraging these advanced measuring equipment, professionals across sectors can enhance their work efficiency and produce high-quality outcomes, be it in auto body repair or intricate manufacturing processes.

Electronic measuring equipment is a versatile and indispensable toolset for professionals across industries. By understanding the nuances of different types, from analog to digital, and exploring their diverse functions, users can maximize their efficiency and accuracy. Incorporating these advanced tips into your workflow ensures you’re harnessing the full potential of your tools, making every measurement reliable and precise.