Frame machine repair is a critical process in auto and collision centers, ensuring vehicle frames meet original specifications after damage. Skilled technicians use specialized equipment for precise measurements and adjustments, impacting steering, handling, and braking systems. Proper tools, regular calibration, high-grade parts, and adherence to manufacturer guidelines are key to achieving high precision, reducing errors, and enhancing overall repair quality, including fender and dent repairs. Standardization of techniques, industry standards, and advanced technologies like CAD software further streamline processes and improve accuracy in frame repairs.

In the realm of precision engineering, frame machine repair stands as a cornerstone of accuracy. This article delves into the intricate relationship between frame machine repair techniques and the resulting precision. From understanding the fundamentals of repair to exploring the significance of proper tooling and calibration, each aspect plays a pivotal role in maintaining consistency and quality. Discover best practices that underscore the importance of meticulous maintenance for optimal frame repairs. Uncover why these methods are essential in ensuring every component meets the highest standards.

- Understanding Frame Machine Repair: The Foundation of Accuracy

- The Impact of Proper Tooling and Calibration on Precision

- Best Practices for Maintaining Consistency and Quality in Frame Repairs

Understanding Frame Machine Repair: The Foundation of Accuracy

Understanding Frame Machine Repair: The Foundation of Accuracy

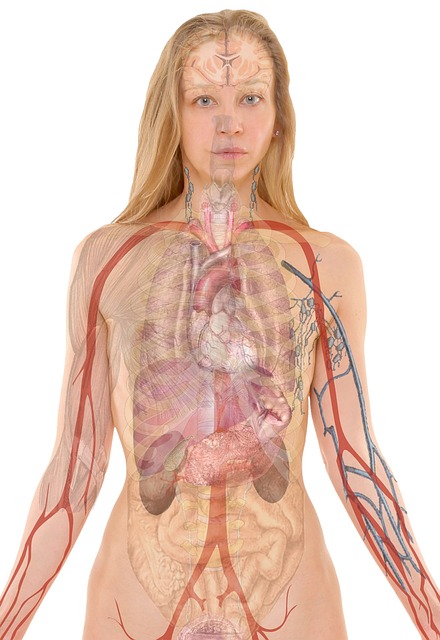

Frame machine repair is a critical component of any auto repair services or collision center. It involves the precise manipulation and realigning of vehicle frames, ensuring they return to their original specifications after an accident or damage. This meticulous process is crucial for maintaining structural integrity and safety standards. A skilled technician uses specialized equipment to accurately measure and adjust various points on the frame, from wheel alignment to suspension components.

Proper frame machine repair lays the foundation for overall vehicle accuracy, including steering, handling, and braking systems. When a collision center performs this task effectively, it not only restores the vehicle’s pre-accident condition but also enhances its performance and longevity. This is particularly important in today’s world where vehicles are designed with advanced safety features that rely on precise frame alignment to function optimally.

The Impact of Proper Tooling and Calibration on Precision

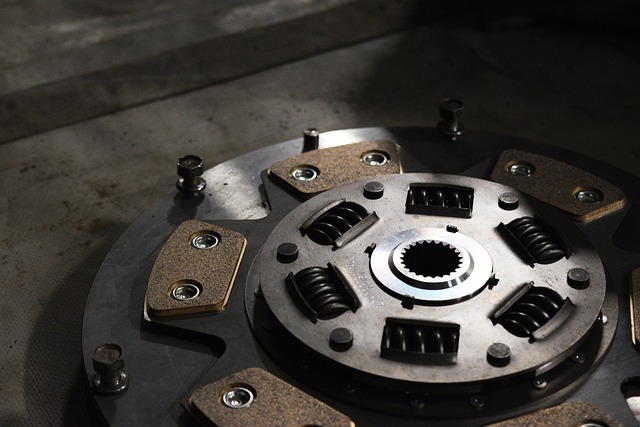

Proper tooling and calibration are cornerstones of achieving high precision in frame machine repair. The right tools, maintained and calibrated regularly, ensure that every repair step is executed with accuracy, from measuring bent frames to straightening them. This meticulous approach significantly reduces errors, making it easier for technicians to deliver top-tier vehicle repair services, including fender repair and vehicle dent repair.

Calibrated machines provide consistent results, which is critical in aligning components precisely. This attention to detail not only guarantees structural integrity in frame machine repair but also enhances the overall quality of related vehicle repair services, such as fender repair and vehicle dent repair. The impact extends beyond individual repairs; it contributes to safer vehicles on the road by ensuring that frames are structurally sound after any mishap.

Best Practices for Maintaining Consistency and Quality in Frame Repairs

Maintaining consistency and quality in frame machine repair is paramount to ensuring accurate and reliable vehicle restoration. Best practices include using high-quality tools and parts, adhering to manufacturer specifications, and implementing rigorous quality control measures throughout the repair process. Frame machines should be regularly calibrated and maintained to guarantee precision, with every step from measurement to welding meticulously documented for traceability.

Consistency in techniques and procedures across different repair shops is also key. Standardized training programs for technicians, adherence to industry standards, and open communication within professional networks help foster uniformity. Moreover, integrating advanced technologies like computer-aided design (CAD) software can streamline measurements, reduce human error, and enhance overall accuracy in both frame repairs and related automotive collision repair or vehicle paint repair tasks, such as fender repair.

Frame machine repair is a critical process that directly impacts the accuracy and quality of structural components. By understanding the fundamentals, utilizing proper tooling and calibration, and adhering to best practices, manufacturers can ensure consistent outcomes. Investing in meticulous frame repairs not only enhances product precision but also contributes to overall operational efficiency and the final integrity of assembled structures.