Advanced technology is transforming traditional vehicle paint inspection by providing unprecedented accuracy and efficiency. Modern devices use sophisticated sensors and algorithms to detect even microscopic imperfections, streamlining collision and auto glass repair processes while enhancing aesthetic finishes. This revolution in auto body shop repairs promises improved quality, reduced costs, and faster defect detection, benefiting both larger service centers and smaller shops. Vehicle paint inspection is becoming a key standard for quality control in the automotive industry, ensuring flawless vehicle finishes upon departure from the shop.

The automotive industry’s pursuit of perfection in vehicle paint inspection has led to a significant shift from traditional methods to advanced technology. This evolution is driving accuracy, efficiency, and quality control. New devices, leveraging cutting-edge sensors and AI, offer unparalleled precision in detecting defects, ensuring consistent paint jobs.

This article explores the advantages of modern technologies over conventional practices, highlights the key features of these innovative tools, and discusses their profound impact on the industry’s future.

- Traditional Methods vs. Advanced Technology for Paint Inspection

- Key Features and Benefits of New Devices

- Industry Impact and Future Prospects

Traditional Methods vs. Advanced Technology for Paint Inspection

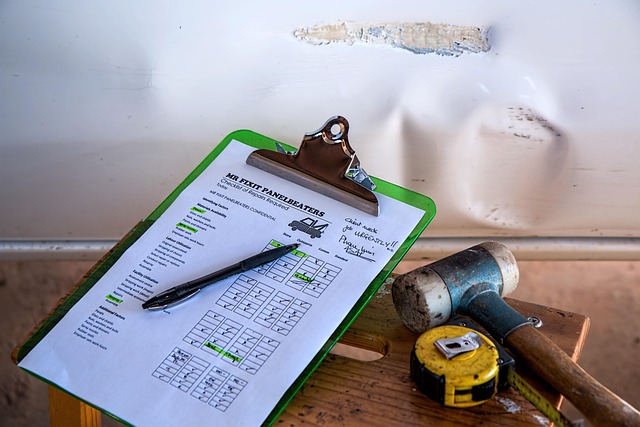

In the realm of vehicle paint inspection, traditional methods have long been the industry standard. These methods often rely on manual examination and subjective judgment, leading to inconsistencies in accuracy. Skilled technicians, while highly trained, can still miss subtle defects or variations in paint job quality. This is where advanced technology steps in as a game-changer.

By contrast, modern devices employing advanced technology offer unprecedented precision in vehicle paint inspection. These tools utilize sophisticated sensors and algorithms to detect even the slightest imperfections, such as car dents or misalignments, that might be overlooked during manual checks. In an auto body shop setting, these innovations are transforming the way repairs are assessed and executed, ensuring that every car dent repair and paint job is of the highest caliber.

Key Features and Benefits of New Devices

New devices are revolutionizing the field of vehicle paint inspection, offering unprecedented accuracy and efficiency. These innovations are designed to detect even the smallest imperfections in a car’s paint job, ensuring a flawless finish. Key features include advanced sensors that can identify microscopic cracks, scratches, and variations in color or texture. This level of detail is crucial for maintaining the aesthetic appeal and resale value of vehicles.

Benefits extend beyond just visual perfection. Accurate vehicle paint inspection using these new devices plays a vital role in car collision repair and auto glass repair processes. By pinpointing issues early on, repairs can be more precise and less invasive, reducing costs and minimizing disruption to the car’s overall structure. This not only enhances the quality of post-repair vehicles but also streamlines the workflow for automotive service centers.

Industry Impact and Future Prospects

The automotive industry is undergoing a significant transformation with the advent of advanced devices for vehicle paint inspection. This technological leap has far-reaching implications for auto repair shops, especially in enhancing the accuracy and efficiency of bumper repair and Mercedes-Benz repair services. The impact is twofold: first, it ensures higher quality finishes, reducing rework and customer dissatisfaction; second, it streamlines the inspection process, allowing mechanics to identify even subtle defects swiftly.

Looking ahead, the future prospects for these devices are promising. As they become more accessible and user-friendly, smaller repair shops can also benefit from this technology, fostering a more competitive and standardized automotive service industry. The potential for error reduction in vehicle paint inspection is not only exciting but crucial, ensuring that every car leaves the shop with a flawless finish—a new benchmark for quality control in auto repair, regardless of whether it’s a bumper repair or intricate Mercedes-Benz restoration.

Advanced devices are transforming the landscape of vehicle paint inspection by offering unparalleled accuracy and efficiency. These new technologies, with their sophisticated features, are revolutionizing quality control processes in the automotive industry. As these innovations continue to evolve, we can expect even more precise and streamlined vehicle paint inspection procedures, ultimately benefiting manufacturers, dealers, and consumers alike.